Torsional vibration reducing device based on hydraulic damping cam

A technology of hydraulic damping and torsional vibration reduction, applied in the direction of rotation vibration suppression, spring/shock absorber, vibration suppression adjustment, etc., can solve the problems of insufficient transmission stability, poor versatility and reliability, etc. To the effect of flowing quickly and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

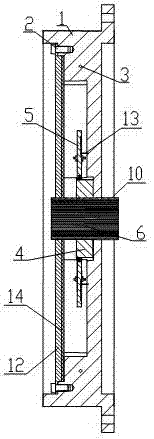

[0033] The present invention will be further elaborated below in conjunction with accompanying drawing:

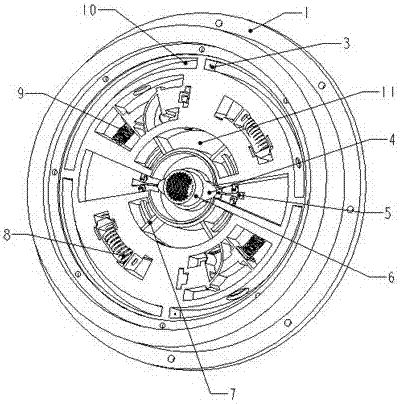

[0034] Such as figure 1 , 2 As shown, the torsional vibration damping device based on the hydraulic damping cam of the present invention mainly includes a flange plate 1, a central cam 4, a cam push rod 5, a spline shaft 6, an arc push rod 7, a direction control window 8, and a decompression window 9. Annular oil tank 10, arc-shaped oil cylinder 11, sealing cover 12.

[0035] The outer edge of the flange 1 is equidistantly provided with a plurality of bolt holes for fixing.

[0036] The sealing cover 12 is screwed to the flange plate through the threaded hole to form a closed space including a decompression window and a direction control window, and the inner cavity of the closed space is filled with oil 15 .

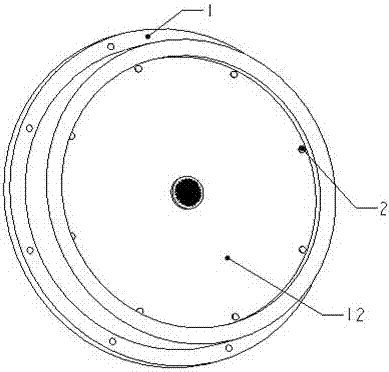

[0037] As shown in FIG. 3 , the outer edge of the flange 1 is provided with a plurality of assembly holes, and the assembly holes are equally spaced.

[0038] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com