Waste heat utilization device of circulating fluidized bed heat supply unit slag cooler

A circulating fluidized bed and heating unit technology, applied in fluidized bed combustion equipment, household heating, heating systems, etc., can solve the problem of reducing the amount of regenerative steam extraction, reducing the effect of regenerative heat, and reducing the effect of waste heat utilization and other problems, to achieve good economy, good heat recovery effect, and improve peak shaving ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and example the present invention will be further described:

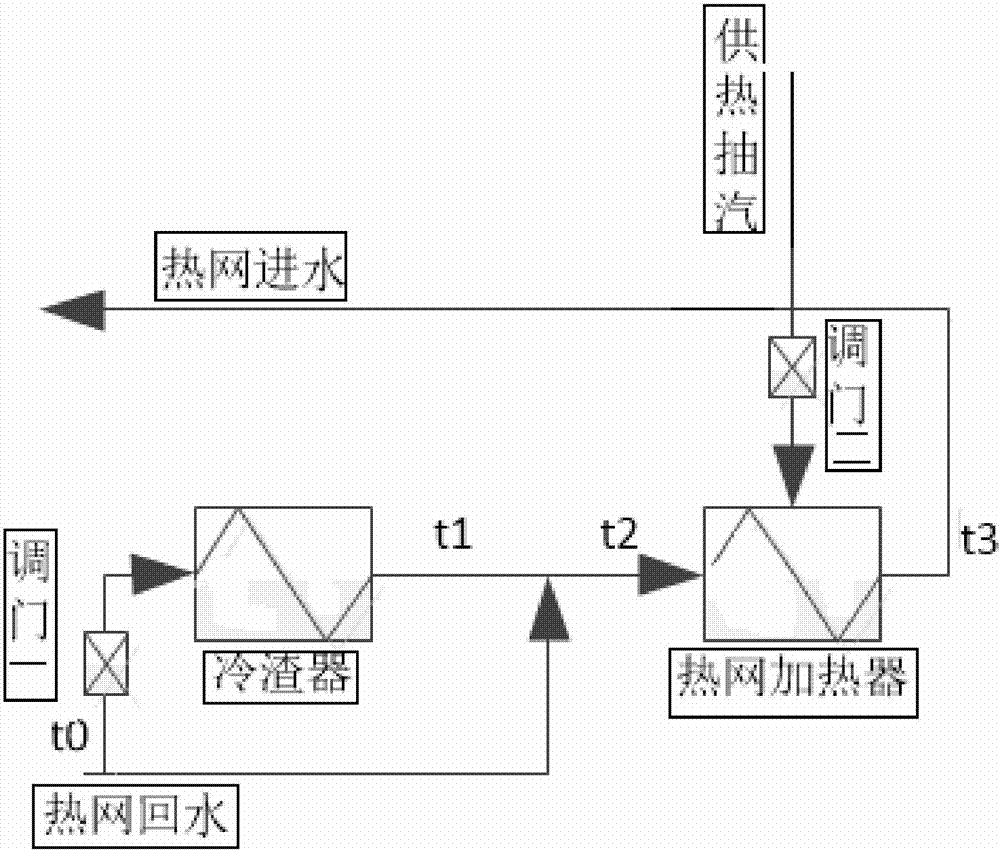

[0012] to combine figure 1 , a circulating fluidized bed heating unit waste heat utilization device for the slag cooler, including a heating network heater, the heating network heater is connected to the main road heating network return water pipeline, and there is a parallel connection on the main road heating network return water pipeline The return water branch pipeline of the heating network, the return water branch pipeline of the heating network is connected with the slag cooler as the pipeline for cooling water to enter the slag cooler, and the cooling water after the slag cooler absorbs heat and heats up and the return water of the main road heating network Converge into one road to connect with the water inlet of the heating network heater. The heating network heater is connected to the four-exhaust steam extraction pipeline. The road is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com