Electric push rod

A technology of electric push rod and transmission screw, applied in the direction of using feedback control, etc., can solve the problems of limited precision, sunlight deviation, large error of electric push rod return to zero accuracy, etc., to achieve rapid response, guaranteed accuracy, and good sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

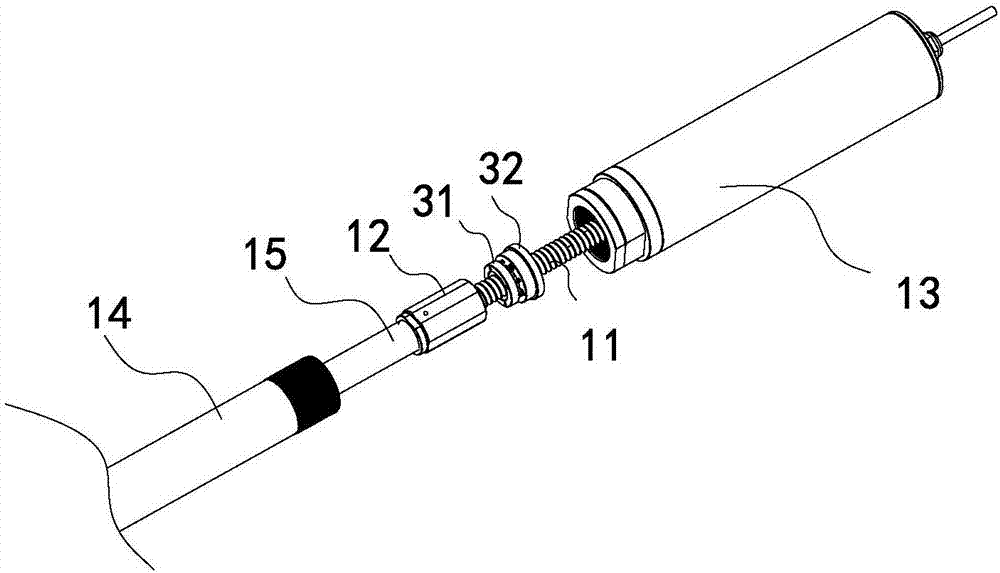

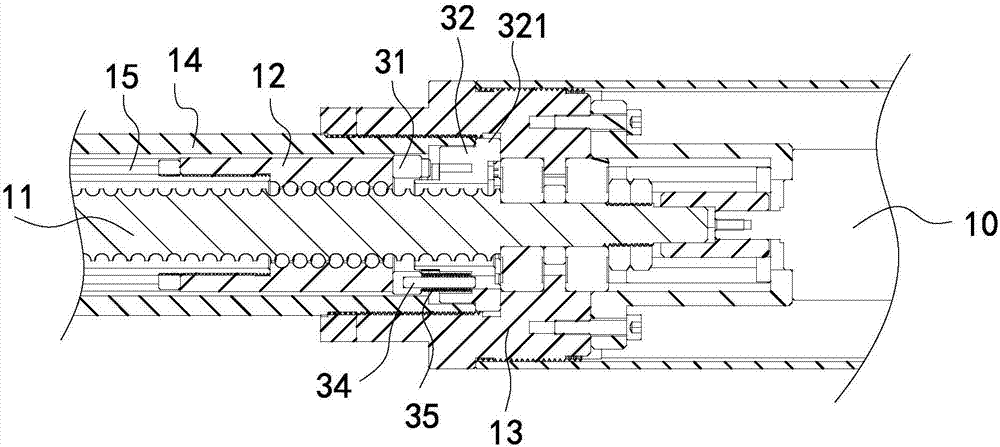

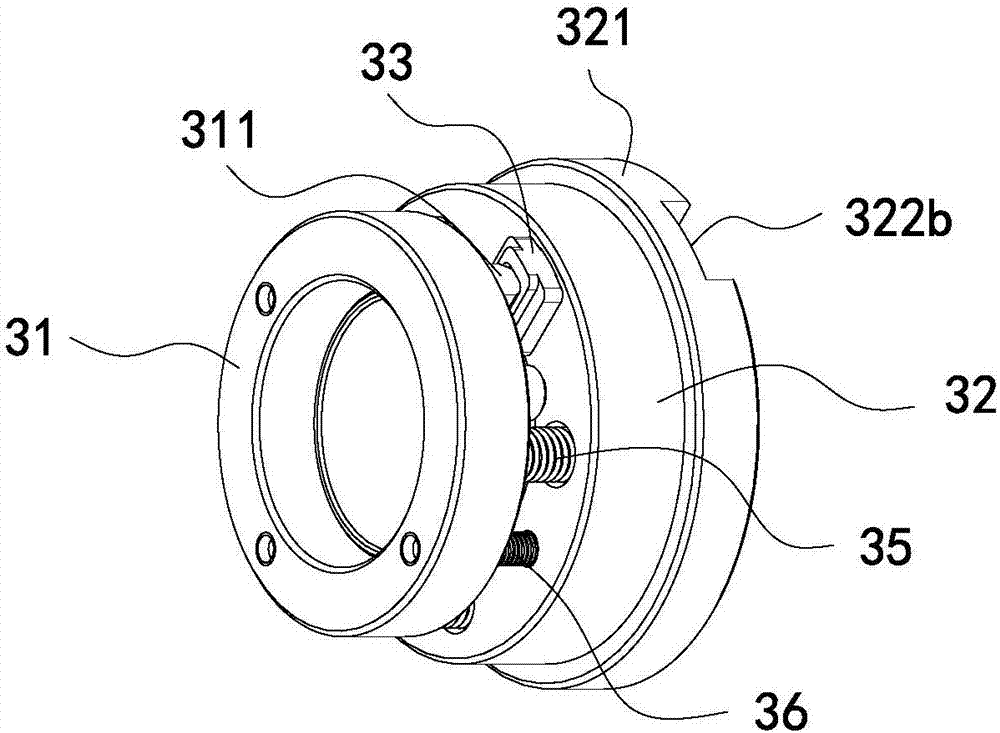

[0033] Such as Figure 1 to Figure 8 As shown, this embodiment shows an electric push rod for solar thermal power generation. This embodiment is mainly used in solar thermal power generation technology to drive heliostats. Of course, it can also be used for other pairs of electric push rods. In the field of high precision, the main structure of the electric push rod in this embodiment includes a motor 10, the motor 10 is connected with a drive screw 11, the drive screw 11 is connected with a nut 12, and the motor 10 is installed in the base 13 , the base 13 is fixedly connected with the outer tube 14, and the nut 12 is fixedly connected with the inner tube 15, when the motor 10 drives the drive screw 11 to rotate, the nut 12 and the drive screw 11 move relatively, specifically in the drive screw 11 The reciprocating movement between the two positions on the nut 12 is a reciprocating movement between an initial position and an extreme position. Overall, the relative movement b...

Embodiment 2

[0051] The difference between this embodiment and Embodiment 1 is that there is no fixed seat in this embodiment, the photoelectric sensor is directly fixed on the base, and the touch panel is also installed on the base, and is installed in a sliding fit with the base. The structure is to set a chute on the base, let the touch plate slide and install in the chute, after the photoelectric sensor is installed on the base, cover it with a protective cover to prevent oil, of course, the protective cover is also set accordingly There is a first opening as in embodiment 1, for the trigger projection to stretch in or out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com