Transformer substation relay protection onsite debugging mobile terminal

A technology for intelligent substation and relay protection, applied in the measurement of electricity, measurement of electrical variables, photometry, etc., can solve problems such as insufficient implementation of technical standards, affecting the quality of engineering debugging, technical exchanges, and technical learning not being timely and in place. , to achieve the effect of speeding up fault handling capabilities, ensuring the quality of engineering debugging, and eliminating multi-version problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Considering the limited space for terminal integration, the bottom board, main board and switch board are designed in combination, that is, the first bottom board, the second main board, and the third switch board. In consideration of the complex working environment on site, the device will be subject to shock or collision, so in order to make the contact firm and prevent the contact from being distorted and deformed, fixed slots are specially designed around the bottom plate, main board, and switch plate.

[0021] The fixed slots are spot-welded around the base plate, main board, and switch board for purely physical connection. Considering the influence of static electricity, a rubber mat is used as the socket body, and the pins are made of plastic long cylinders to complete the three-board fixation.

[0022] The bottom plate, the main board and the switch board all adopt existing conventional products.

[0023] The main function of the terminal integrated base plate ...

Embodiment 2

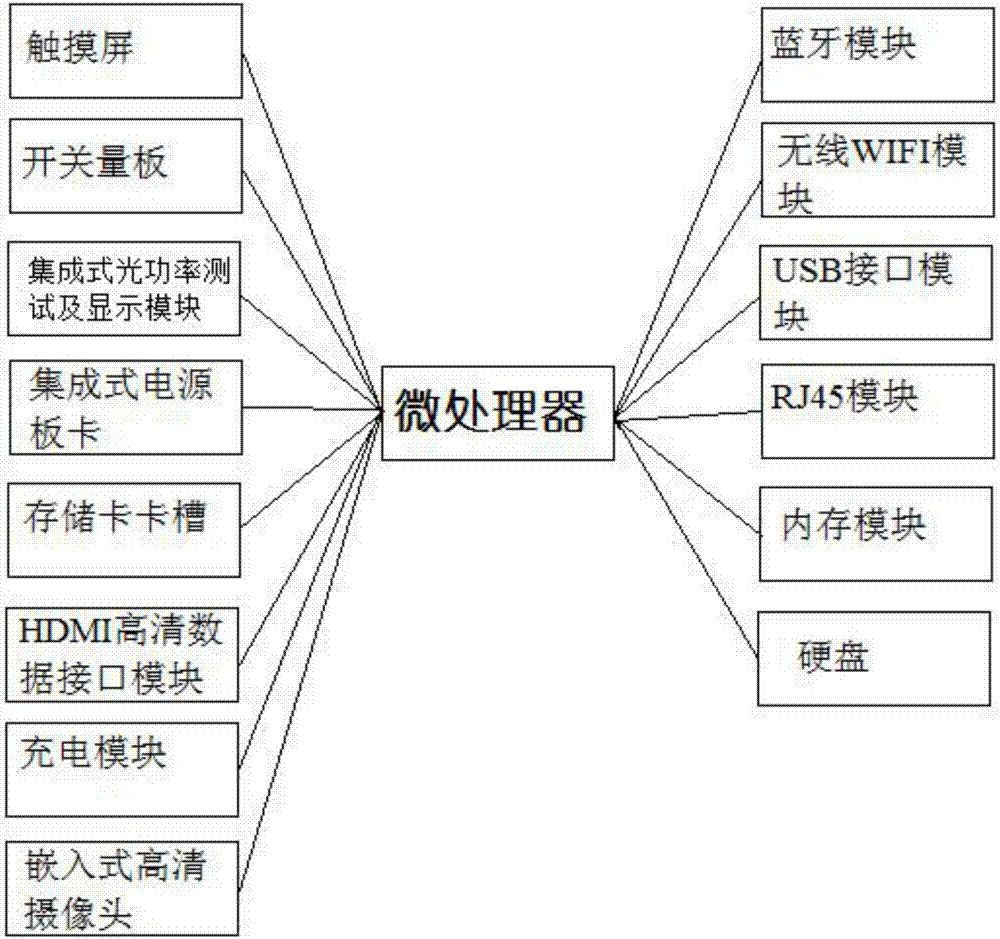

[0045] The intelligent substation relay protection on-site debugging mobile terminal of the present invention is mainly divided into two parts: hardware design and software design. Hardware design mainly includes equipment appearance, terminal equipment body hardware function and distribution design, terminal equipment integrated bottom plate, main board, switch board, integrated optical power test and display plug-in, integrated power supply board, inductive capacitive touch electronic screen, SDXC Slot, high-definition data interface, charging system, terminal equipment tripod bracket, etc. The software design is mainly divided into two system platforms, including the functional application software developed under the FreeRTOS system platform and the XP system platform. The present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation examples.

[0046] The intelligent substation relay protection on-site debug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com