Wound-stacked battery

A stacked battery technology, applied in secondary batteries, secondary battery manufacturing, circuits, etc., can solve the problems of battery safety not being guaranteed, battery cycle performance deterioration, affecting long-term characteristics of batteries, etc., to reduce internal short circuits The risk, the theoretical loss reduction, the effect of low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

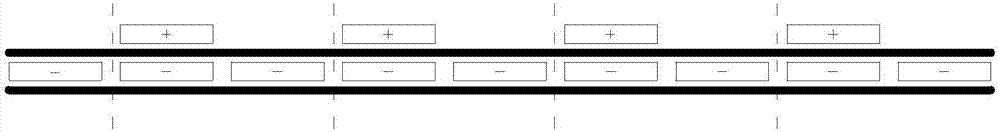

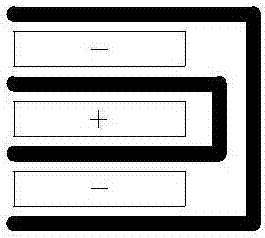

[0058] The winding structure unit has two different structures, figure 1 It is the structure of the winding structure unit one before winding, with two layers of diaphragms in parallel, the negative pole piece is set in the middle of the two layers of diaphragms, and the positive pole piece is spaced above the diaphragm, and the winding structure unit one after winding 0.5 turns structured as figure 2 As shown, the structure of the winding structure unit 1 is separator / negative electrode / diaphragm / positive electrode / diaphragm / negative electrode / diaphragm, image 3 It is the structure before the second winding of the winding structure unit. Two layers of separators are arranged in parallel. The negative pole piece is set in the middle of the two layers of membranes. The structure of the second winding structure unit is as follows Figure 4 As shown, the structure of the winding structure unit 2 is positive electrode / diaphragm / negative electrode / diaphragm / positive electrode / d...

Embodiment 2

[0060] The difference from Example 1 lies in the difference of the winding structure unit, the winding structure unit has two different structures, Figure 6 It is a winding structure unit-the structure before winding, with two layers of diaphragms in parallel, the negative pole piece is set in the middle of the two layers of diaphragms, and the positive pole pieces are respectively arranged above the first layer of diaphragm and below the second layer of diaphragm, winding The number of turns can be 0.5*N (N is an odd number), and the winding structural unit after winding 1.5 turns has a structure such as Figure 7 As shown, the structure of the winding structure unit 1 is separator / negative electrode / diaphragm / positive electrode / diaphragm / negative electrode / diaphragm / positive electrode, such as Figure 8 The structure of the winding structure unit 2 shown is diaphragm / negative electrode / diaphragm. The two winding structure units 1 are stacked in sequence. After stacking, the...

Embodiment 3

[0062] The difference with embodiment 1 is that the winding structure unit is different, and the winding structure unit has two different structures, such as Figure 10 As shown, the structure of the wound structure unit 1 is separator / negative electrode / separator / positive electrode, such as Figure 11 As shown, the structure of the wound structure unit 2 is separator / negative electrode / separator, such as Figure 12 As shown, four sets of winding structural units are stacked in sequence, and after stacking, the two sides are respectively the separator and the positive electrode sheet, and the outermost layer is the side of the positive electrode sheet, and a set of winding structural units are stacked on this side to form a battery electrode group.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com