Cable plugging type connector for transformer

A plug-in, transformer technology, applied in the direction of transformer/coil connectors, circuits, connections, etc., can solve the problems of inconvenient installation, long cable handling length, and lack of waterproof performance of the main body of the joint, so as to improve fastness and guarantee tightness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

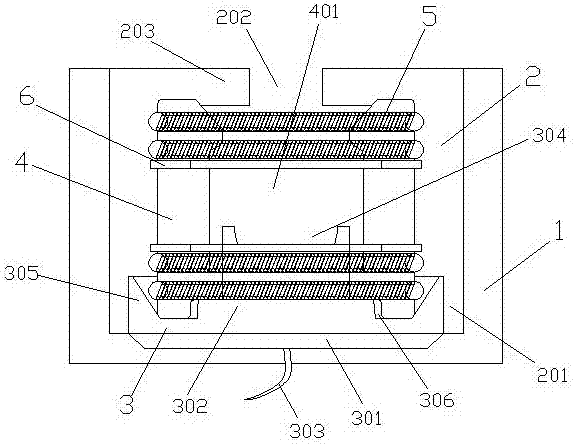

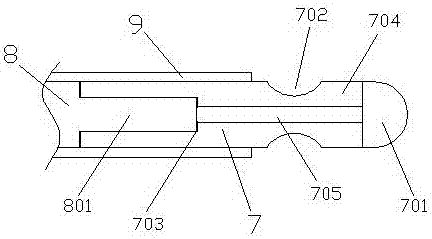

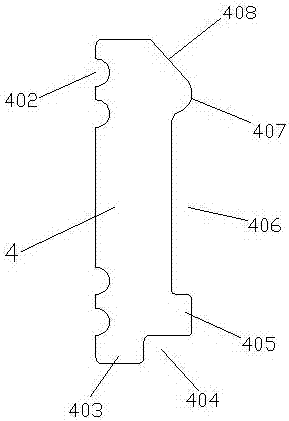

[0022] As shown in the figure, a cable plug-in connector for a transformer includes a female head and a sub-head that cooperate with each other. The female head includes an insulating sleeve 1 with one end open and the other end closed, and a conductive card arranged at the bottom of the insulating sleeve 1. seat 3 and several arc-shaped fixing plates 4, wherein the bottom of the conductive card seat 3 is provided with a wire 303 leading out of the insulating sleeve 1, and the outer edge and center of the conductive card seat 3 are respectively provided with an annular baffle 305 and a circular convex platform 302, the bottoms of the plurality of arc-shaped fixed plates 4 are all movably arranged in the annular groove 306 formed between the annular baffle plate 305 and the circular boss 302, so that each arc-shaped fixed plate 4 can be placed in the annular groove 306 moves along the radial direction of the annular groove 306; the upper and lower parts of the outer sides of all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com