Non-uniform partitioned permanent magnet linear synchronous motor excitation topology structure and design method thereof

A permanent magnet linear synchronization and non-uniform block technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit, electrical components, etc., can solve the problems of affecting optimization efficiency, reducing the maximum rated thrust of the motor, and small overload capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] The motor mainly consists of primary, secondary and air gap.

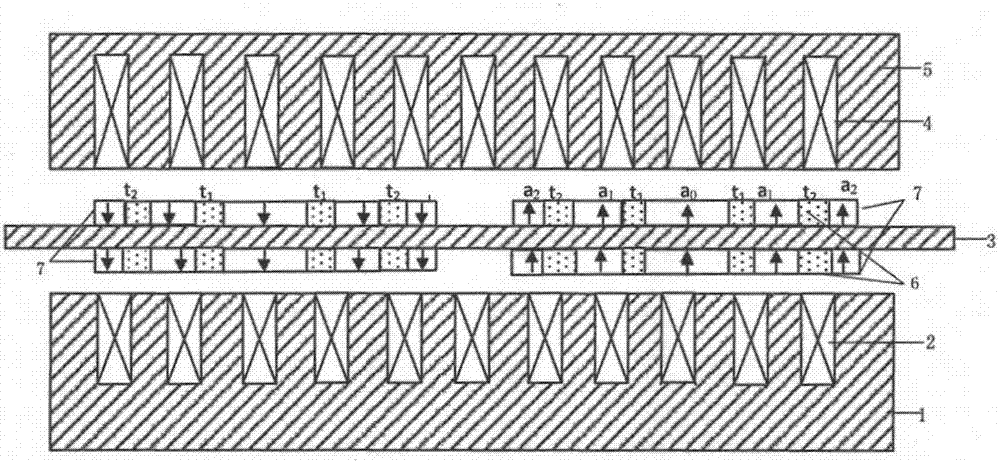

[0070] Such as figure 1 As shown, the primary side of the bilateral cylindrical permanent magnet linear synchronous motor is divided into inner and outer double-layer structures, consisting of an inner stator and an outer stator.

[0071] The outer stator includes an outer primary core 5 and an outer armature winding 4 . The outer primary iron core 5 is located at the outermost side of the motor and is of tubular structure, and the outer layer armature winding 4 is tightly fixed inside the outer primary iron core 5 .

[0072] The inner stator includes an inner primary core 1 and an inner armature winding 2 . The inner primary iron core 1 is located at the innermost side of the motor and is also of tubular structure, and the inner armature winding 2 is tightly fixed outside the inner primary iron core 1 .

[0073] The inner armature winding 2 and the outer armature winding 4 are connected in series, and bo...

Embodiment 2

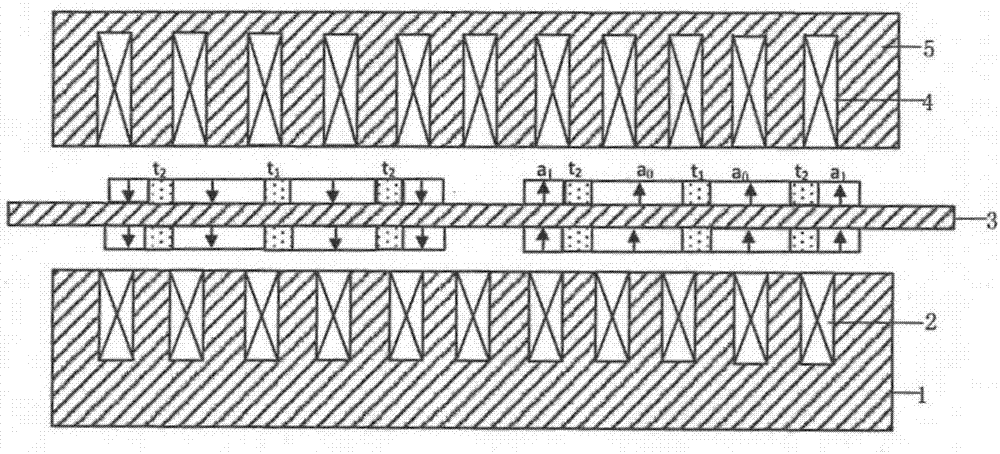

[0098] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the permanent magnet has a non-uniform even-numbered block topology.

[0099] Let the width of the two permanent magnet blocks in the middle be a 0 ; The width of each permanent magnet block extending to both ends is a 1 、a 2 ,...,a n ;a i =a 0 *q i , i=1, 2, 3,...n, n is a positive integer, 01 , t 2 ,...,t n+1 ; The relationship between its harmonic content and design variables is:

[0100]

[0101]

[0102] B r is the residual magnetism, μ r is the relative magnetic permeability, h m is the thickness of the magnetized permanent magnet.

[0103] for image 3 For an example, take n=2 as an example for illustration.

[0104] According to the factor level constraints a 0 p ; When the pole distance τ of the permanent magnet p is a certain value, in the variable interval [a d , a e ] to select a 0 The value of , in the interval [t f , t g ] select t 1 , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com