Non-uniform disturbance electrical sparkle micro hole machining device

A processing device and non-uniform technology, which is applied in the field of metal processing and EDM micro-hole processing, can solve the problems such as the difficulty of removing electro-corrosion products, achieve a large flow of working fluid, prevent congestion of electro-corrosion products, and prevent non-uniform side walls The effect of discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

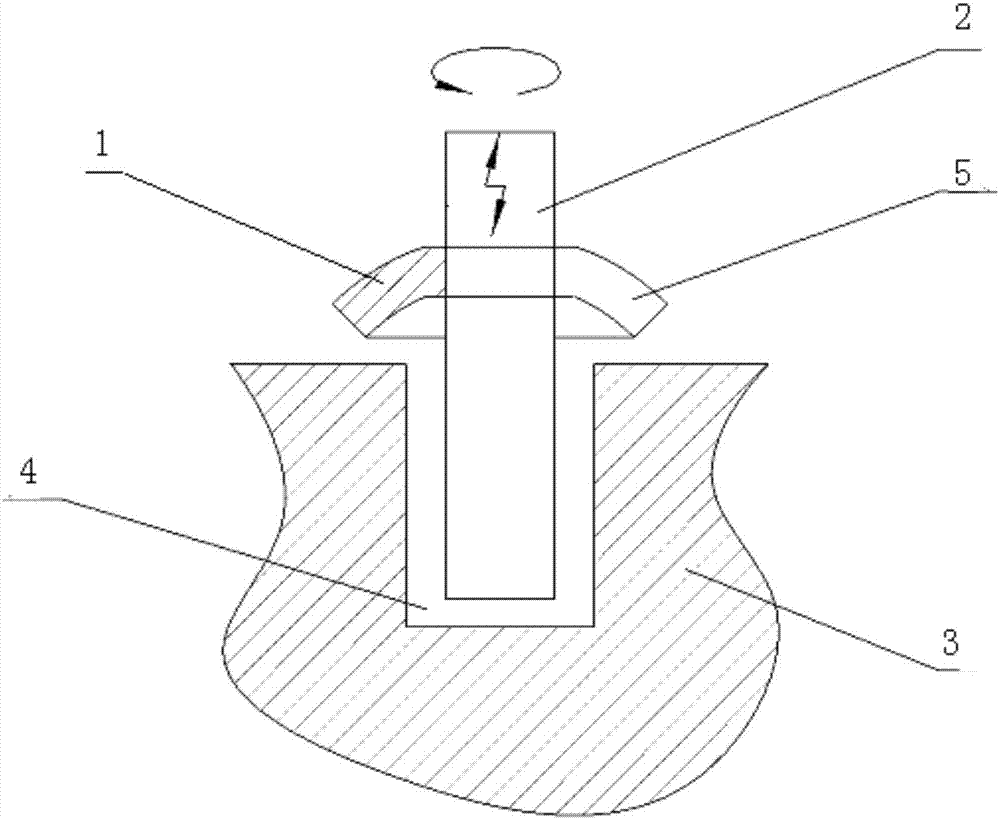

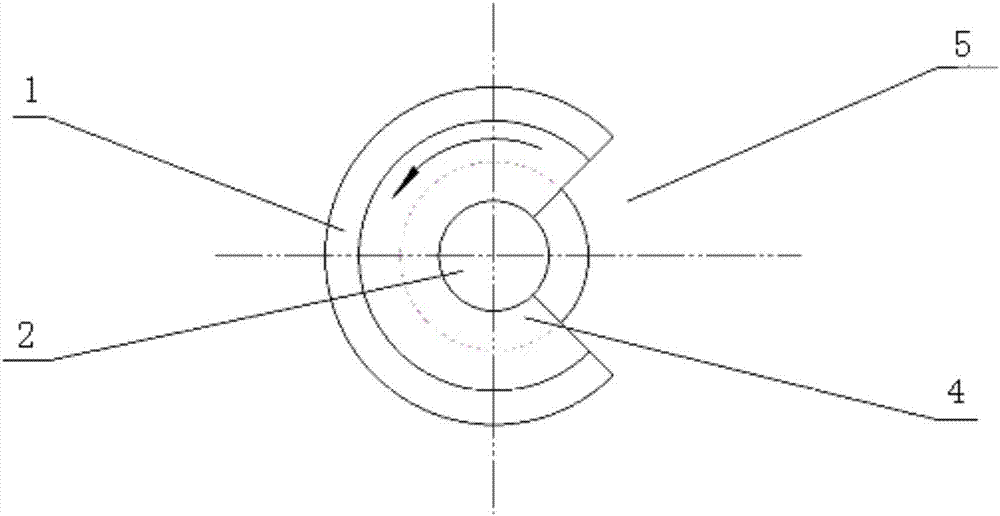

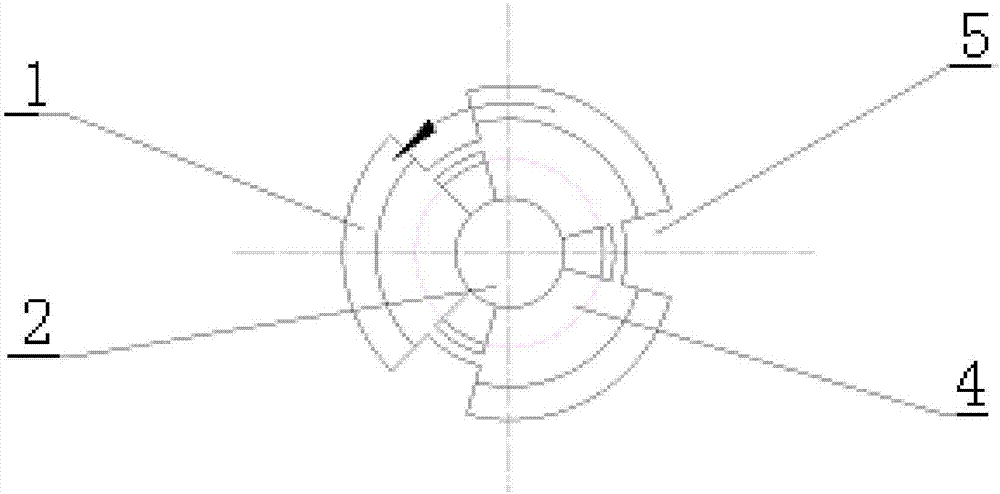

[0023] Attached below image 3 And the specific embodiment will further illustrate the present invention:

[0024] The non-uniform disturbance electric discharge micro-hole machining device includes electric discharge machining equipment. The tool electrode 2 of the electric discharge machining equipment has a compound motion of rotation and vibration during the machining process. The tool electrode 2 is equipped with a non-uniform disturbance actuator 1. The non-uniform disturbance actuator 1 is a disc with notches. There are more than one notch. The central hole of the disk is installed on the tool electrode 2 through a rubber ring, and is located above the workpiece 3 to be processed. The gap between the edge of the non-uniform disturbance actuator 1 and the upper surface of the workpiece is m, and 0mm≤m≥the amplitude of the tool electrode 2.

[0025] The working process of the present invention is: in the downward stage of the vibration of the tool electrode 2, the tool e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com