Parallel-microchannel water-cooling base plate

A water-cooled substrate and micro-channel technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., to ensure no deformation and reduce the deformation of aluminum plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

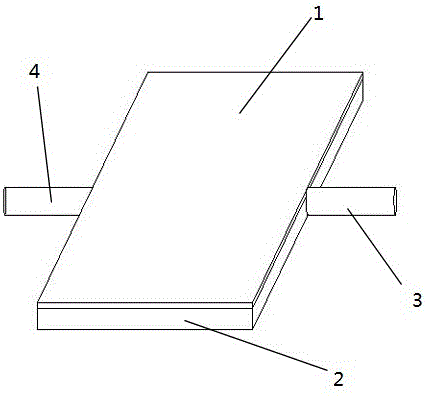

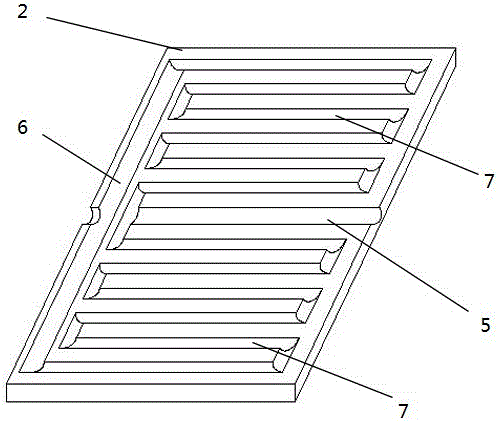

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0016] Such as figure 1 , figure 2 Shown on the water cooling system loop. In the main circulation loop, the cooling medium (water) flows through the cooled device to cool it. At the same time, the medium absorbs heat and flows through the air cooler for secondary heat dissipation. The heat-dissipated medium enters the next cycle under the action of the main circulation pump. This goes back and forth; the voltage stabilization circulation system provides voltage stabilization for the water-cooled substrate circulation circuit and the secondary heat dissipation circuit; the main test platform frame is used to cooperate with the IGBT water-cooled substrate performance test and the assembly and support of its auxiliary equipment. Each data signal of the system is collected and processed by Agilent 34980A data acquisition instrument.

[0017] The water-cooled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com