a punching device

A technology of punching device and dimples, which is applied in the field of fabric processing, can solve the problems of great significance, inability to accurately position the lower mold, errors and other problems of luggage companies, and achieve increased profit margins, fast work efficiency and good molding effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

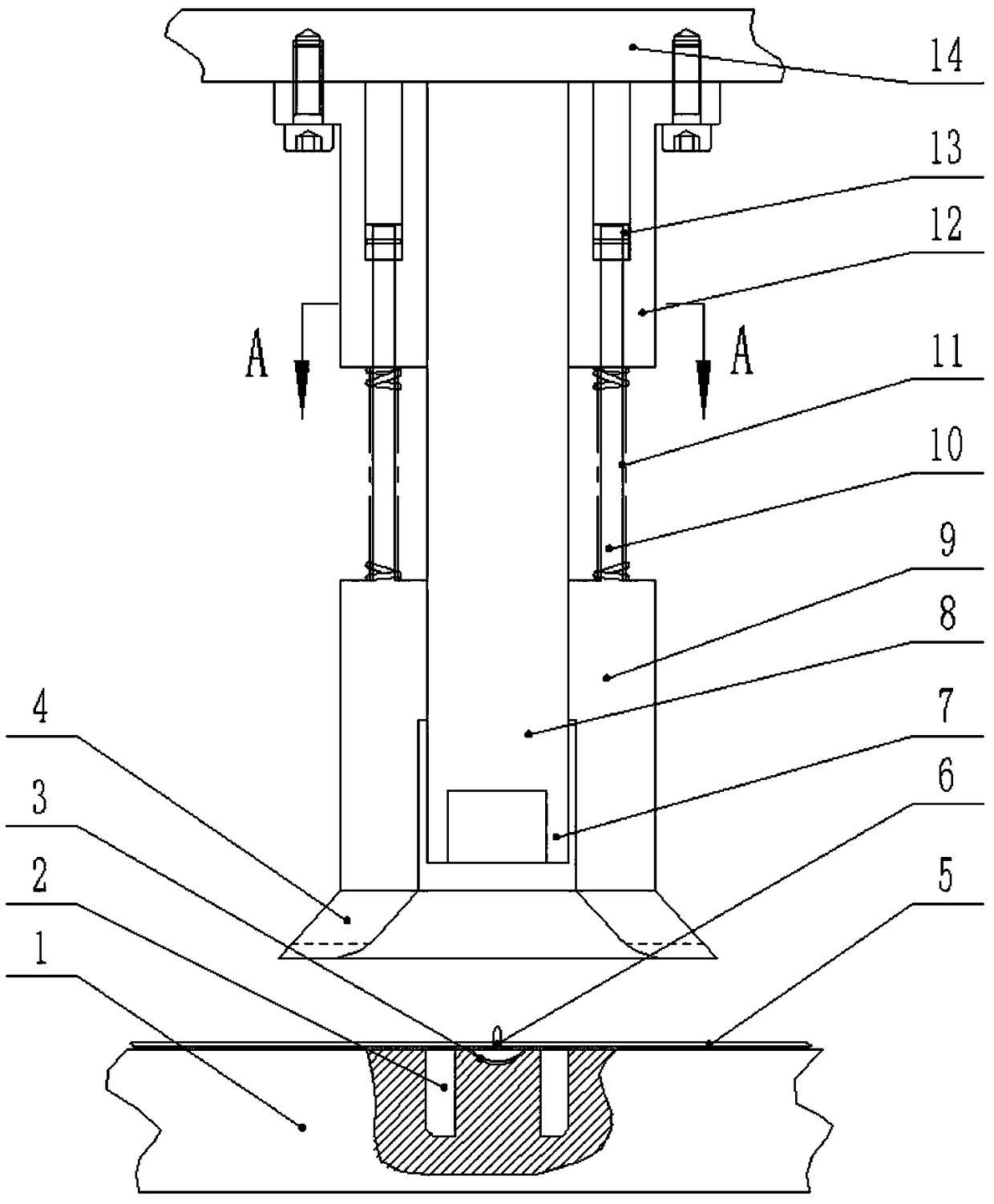

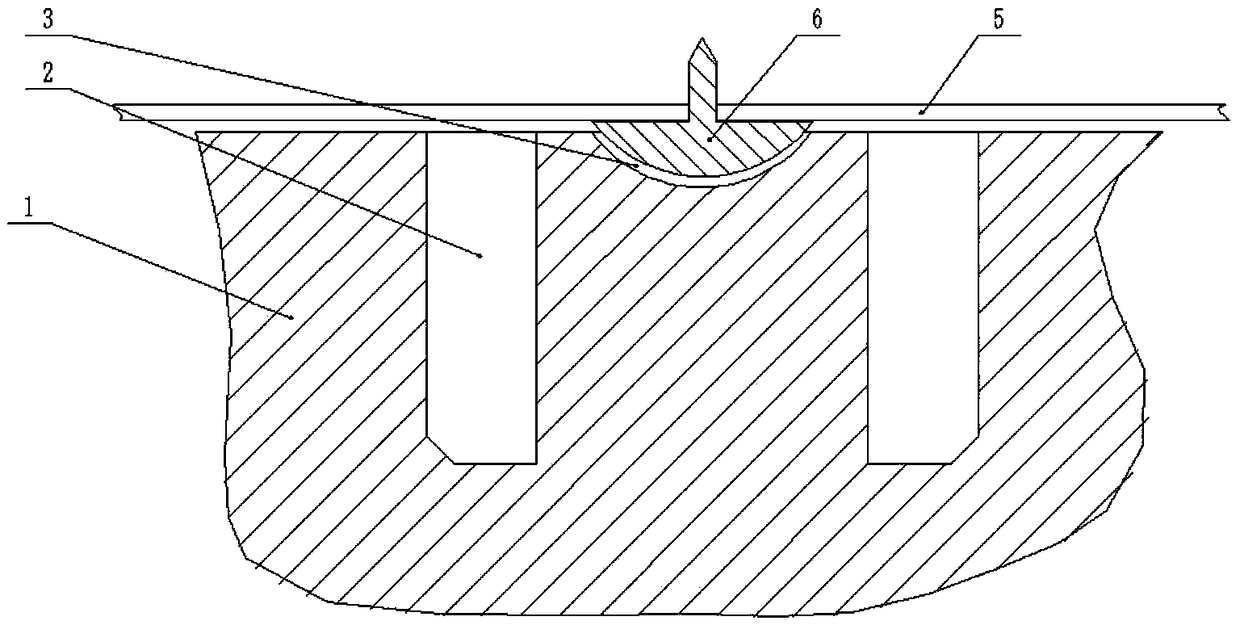

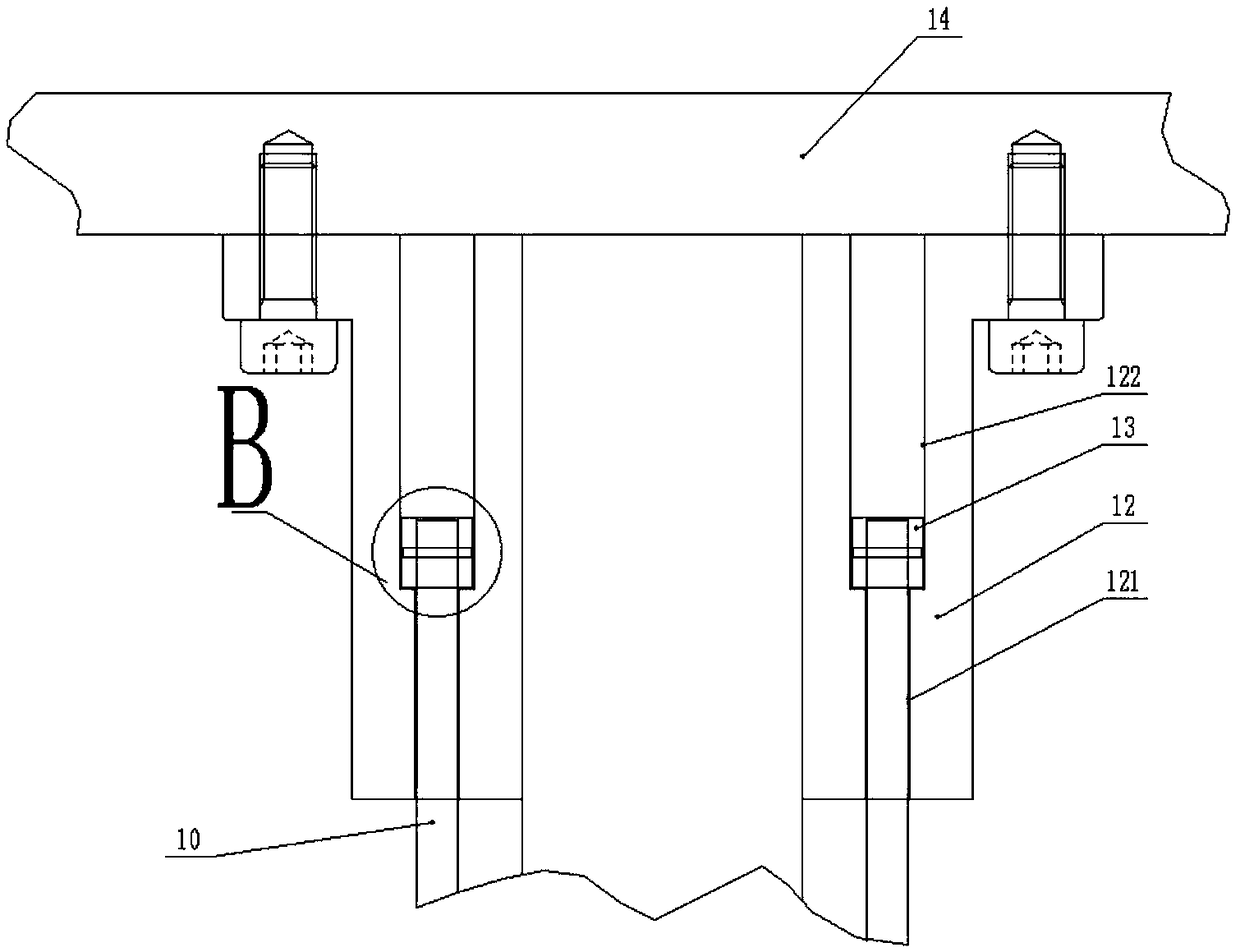

[0026] As shown in the figure, a punching device according to an embodiment of the present invention includes: figure 2 As shown, the workbench 1 is processed with an annular groove 2 and a pit 3, the pit 3 is located in the middle of the annular groove 2, and the shape of the pit 3 is consistent with the shape of the bottom 61 of the tack 6; as figure 1 As shown, the lifting platform 14 is located above the workbench 1, and the lifting platform 14 is driven by the power mechanism to move up and down, as figure 1 , image 3 As shown, the lower surface of the lifting table 14 is concentrically installed with a central shaft 8 and a fixed sleeve 12, the position of the central shaft 8 corresponds to the pit 3, the lower end of the central shaft 8 is fixed to the cutter head 7, and the cutter head 7 is matched with the annular groove 2, fixed Processing through hole 121, through hole I122 in cover 12, as Figure 4 As shown, the size of the through hole I122 is larger than that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com