Novel stirrer

A mixer and a new type of technology, which are used in cement mixing devices, liquid batching supply devices, clay preparation devices, etc., can solve the problems of incompatibility and reduced concrete mixing effect, improve the applicable surface and functionality, and achieve high-performance anti-consolidation. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

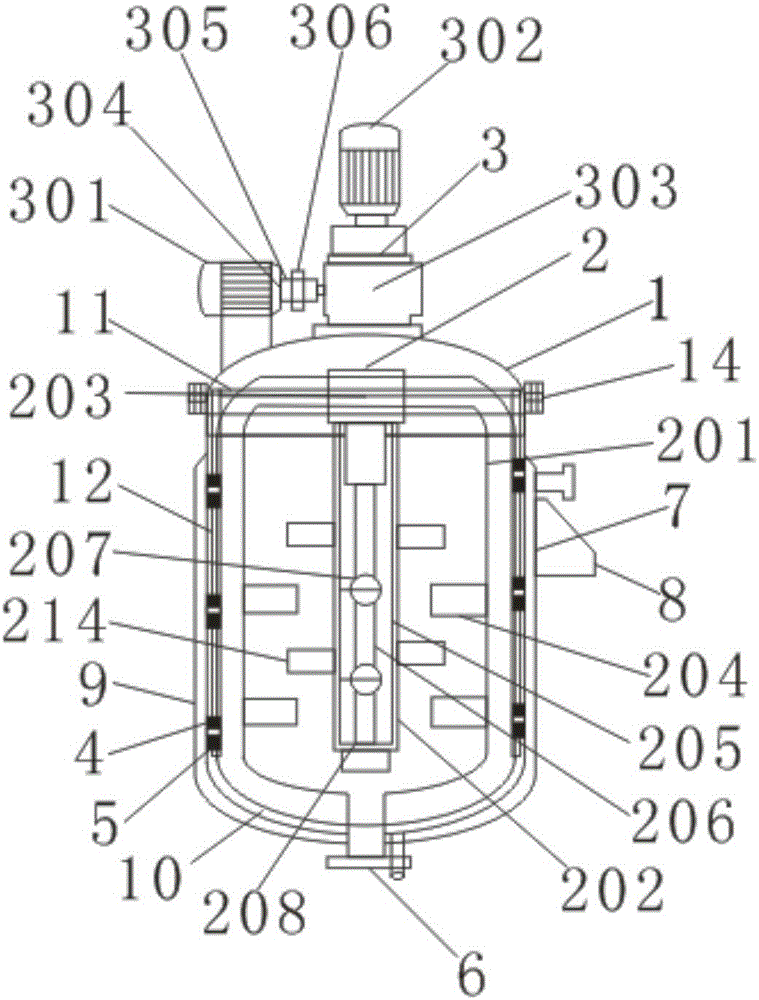

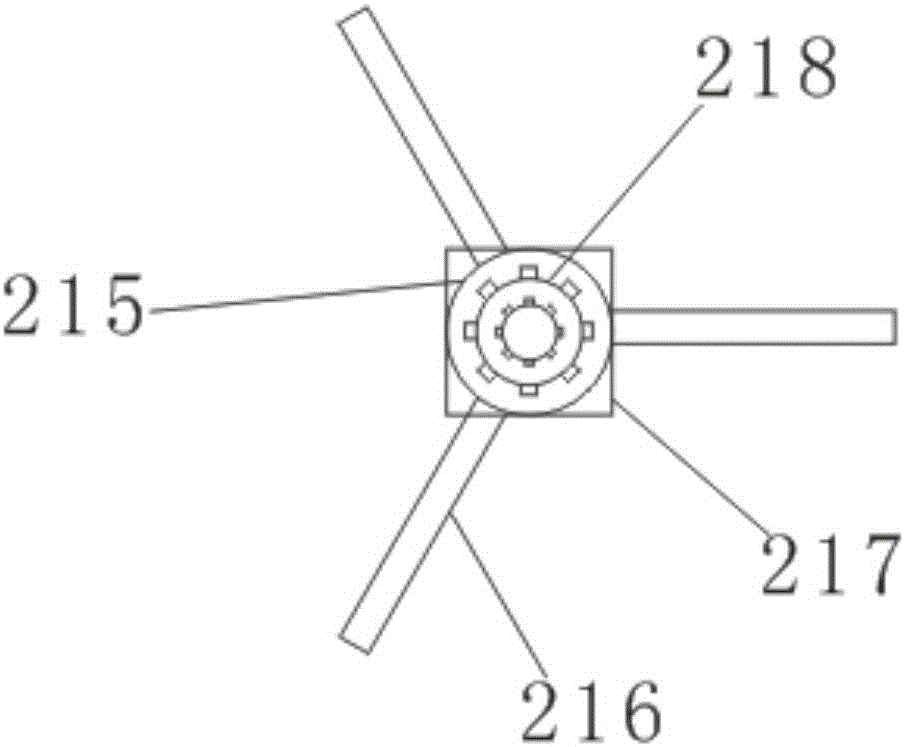

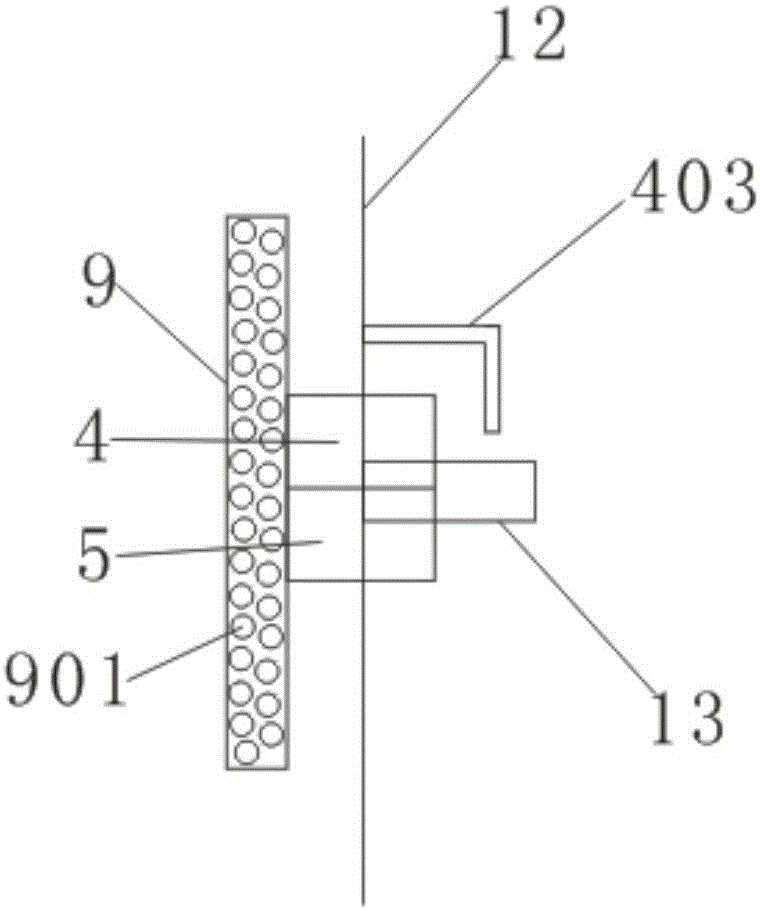

[0028] Such as Figure 1 to Figure 7 As shown, the present invention provides a new type of mixer, including a cylinder 1, a linkage shaft 2, a stirring drive device 3, a humidity controller 4 and a temperature controller 5, the cylinder 1 is in the shape of an ellipse, and the cylinder 1 The bottom and the side are respectively provided with a discharge ball valve 6 and a feed inlet 7, and a feed hopper 8 is fixedly installed on the feed inlet 7, and the linkage shaft 2 passes through the cylinder 1 and is fixedly installed on the top of the cylinder 1, A suspension plate 11 is also fixedly installed on the top of the cylinder body 1. The suspension plate 11 is symmetrically distributed in the direction of the longitudinal axis of the linkage shaft 2, and is independently separated in the middle of the suspension plate 11. There are also two ends of the suspension plate 11. There are jacking bolts 14, and the suspension plate 11 is horizontally fixed on the top of the cylinde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com