A 3D printer nozzle function abnormality detection system

A 3D printer and detection system technology, applied in 3D object support structures, manufacturing tools, processing data acquisition/processing, etc., can solve problems such as uneven temperature distribution of heating blocks, poor printing model effect, clogged nozzles, etc., to simplify operations , improve the effect and save resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

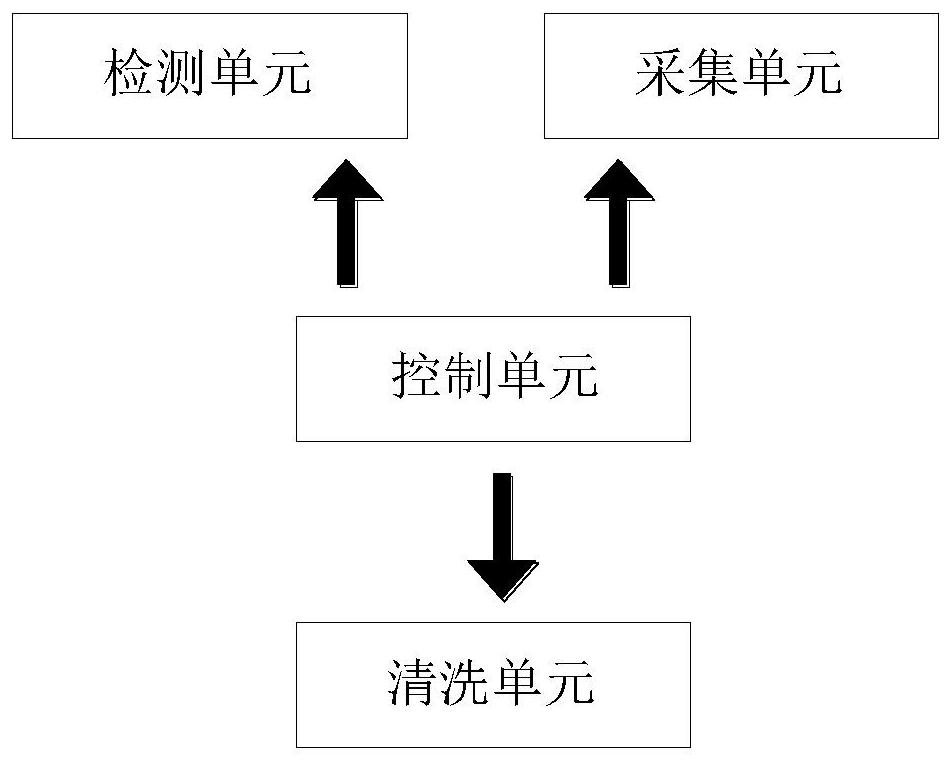

[0022] Such as figure 1 as shown, figure 1 A 3D printer nozzle function abnormality detection system proposed for the present invention.

[0023] refer to figure 1 , the 3D printer nozzle function abnormal detection system proposed by the present invention, comprising:

[0024] The detection unit includes a liquid storage tank and n detection modules. Any detection module includes a nozzle, an infusion tube, and a solenoid valve. One end of the infusion tube is connected to the liquid storage tank, and the other end is connected to the nozzle. The solenoid valve is communicated with the control unit;

[0025] The acquisition unit is used to collect video information when the nozzle ejects liquid; in this embodiment, the acquisition unit adopts a high-definition camera, and the high-definition camera can improve the clarity of the video information when collecting the nozzle ejection liquid. The unit analyzes the above video information to provide an accurate reference.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com