Thermal transfer printing type printer and method for supplying consumable materials for thermal transfer printing

A thermal transfer printing and printer technology, applied in printing devices, printing, inking devices, etc., can solve problems such as complicated installation process of consumables, poor user experience, and large printer size, and achieve enhanced user experience, reduced volume, and simplified installation The effect of steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

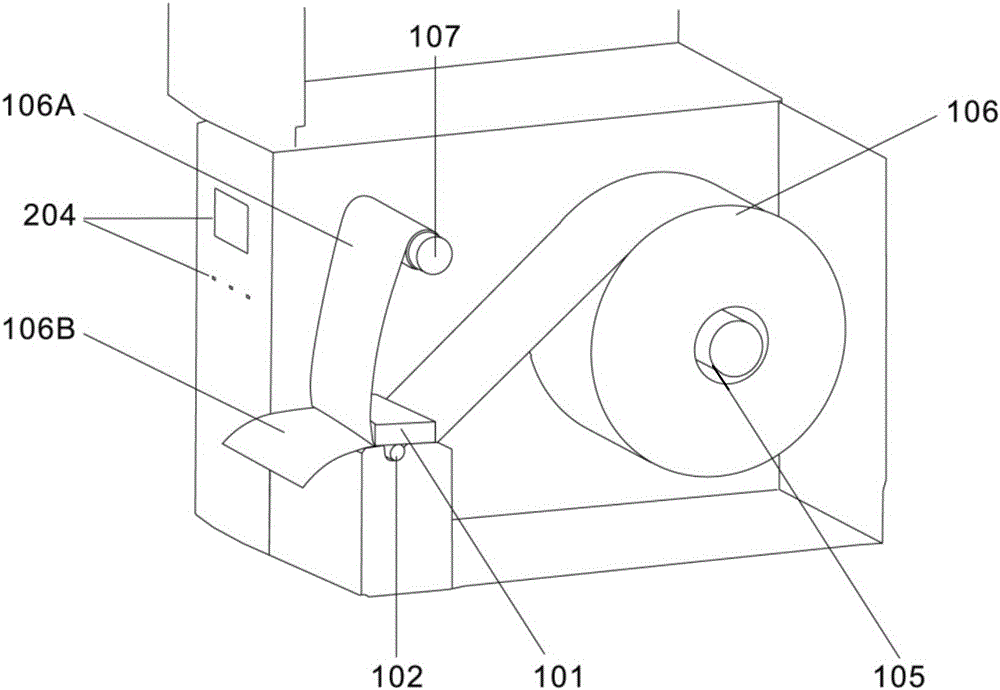

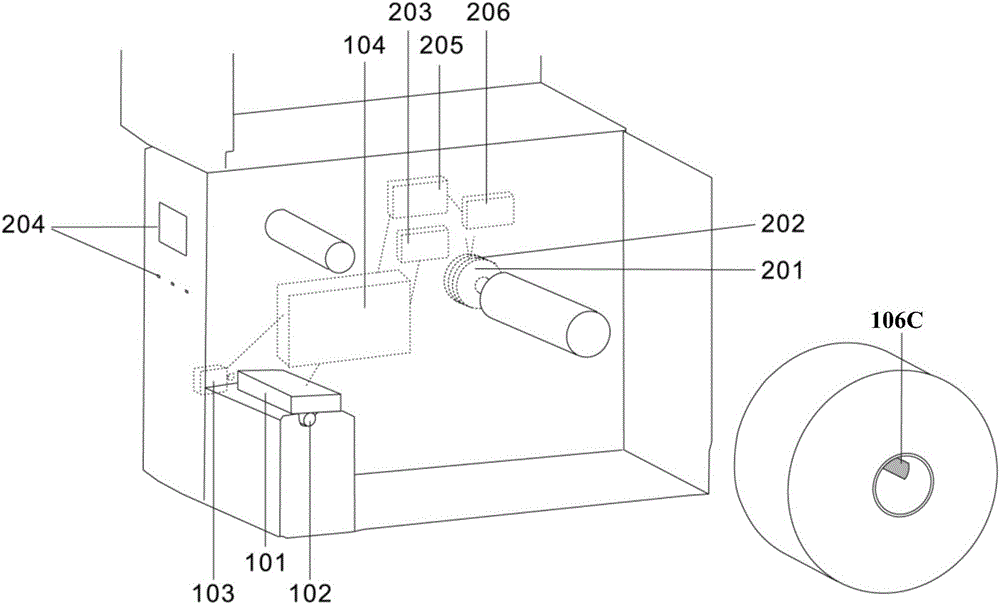

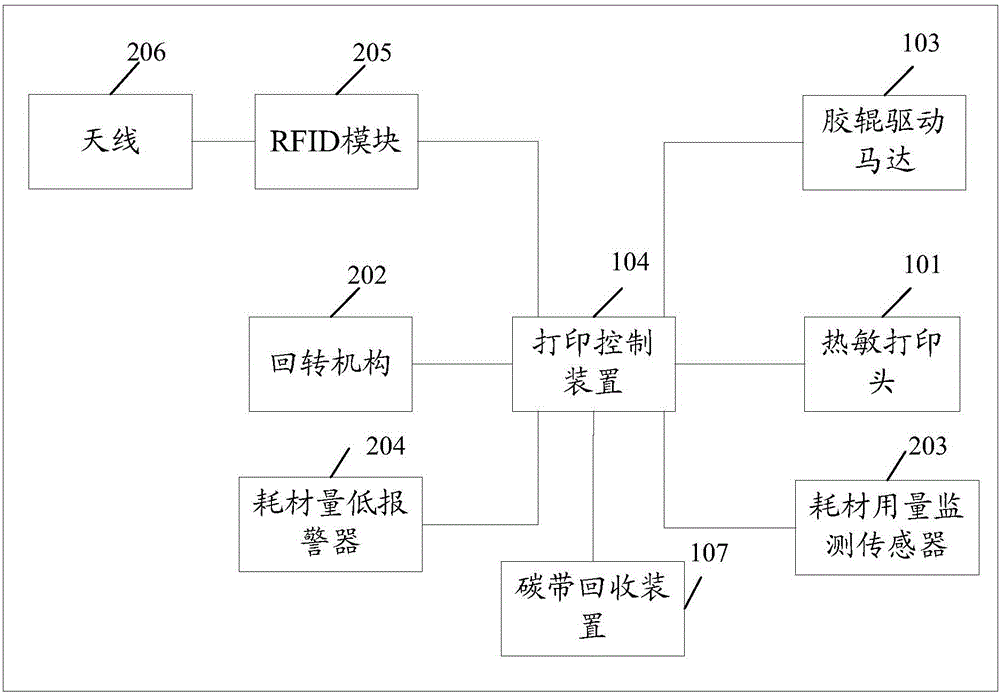

[0037] An embodiment of the present invention provides a thermal transfer printer, see figure 1 , the thermal transfer printer includes:

[0038] The consumable material supply device 105 is used to install a specific composite consumable material 106, which is prepared by attaching the ink surface of the thermal transfer ribbon 106A to the surface of the printing roll paper 106B and winding the same shaft. In this way, when installing the composite consumables 106, the user can add the thermal transfer ribbon 106A and the printing roll paper 106B to the printer at the same time, instead of installing them separately, which reduces the complexity of installing the printer consumables and brings better user experience to the user. . At the same time, the thermal transfer printer only needs to set up one consumable supply device 105, which can satisfy the installation of the thermal transfer ribbon 106A and the printing roll paper 106B, instead of setting up two different consu...

Embodiment 2

[0057] An embodiment of the present invention provides a method for supplying thermal transfer consumables, which is applicable to the thermal transfer printer described in Embodiment 1, see image 3 , the method can include:

[0058] Step S21 , installing specific composite consumables to the consumable supply device of the thermal transfer printer. The composite consumables are prepared by bonding the ink surface of the thermal transfer ribbon to the surface of the printing roll paper and winding the same shaft.

[0059] In this embodiment, a specific composite consumable is installed on the consumable supply device, and the composite consumable is prepared by attaching the ink surface of the thermal transfer ribbon to the surface of the printing roll paper and winding the same shaft, so that when the user installs the composite consumable Thermal transfer ribbon and printing roll paper can be added to the printer at the same time, instead of installing them separately, whic...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap