Tool platform suitable for positioning of cast-in-place pile reinforcement cage and guide pipe

A technology for positioning platform and reinforcement cage, applied in sheet pile wall, infrastructure engineering, construction and other directions, can solve the problems of small operation surface, many sections of reinforcement cage of pile body, increased work intensity of operators, etc., so as to improve operation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

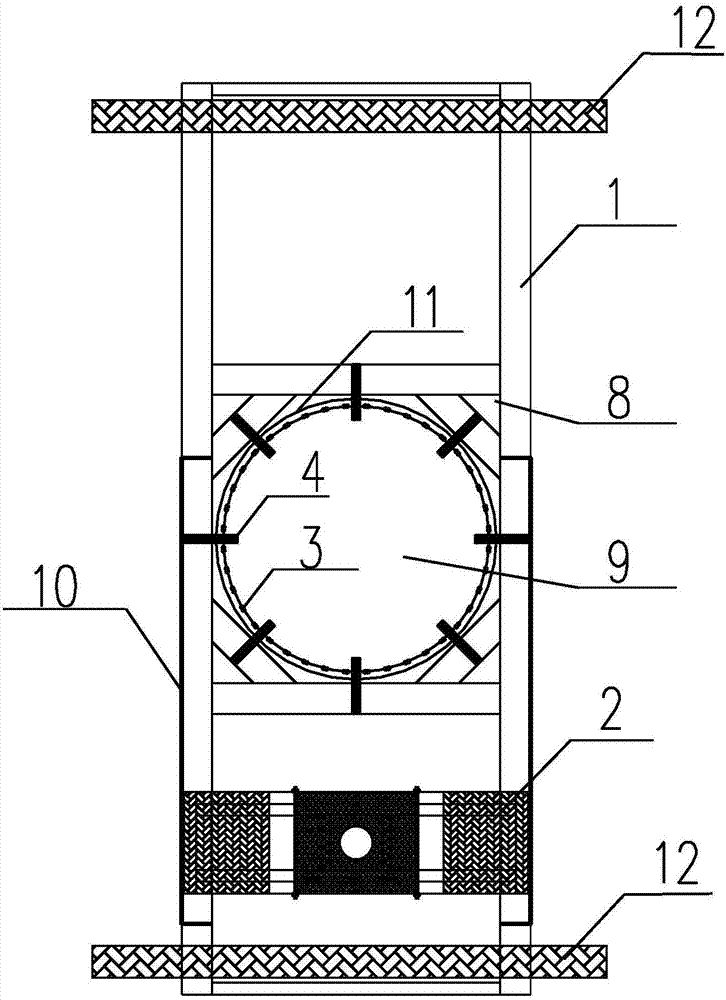

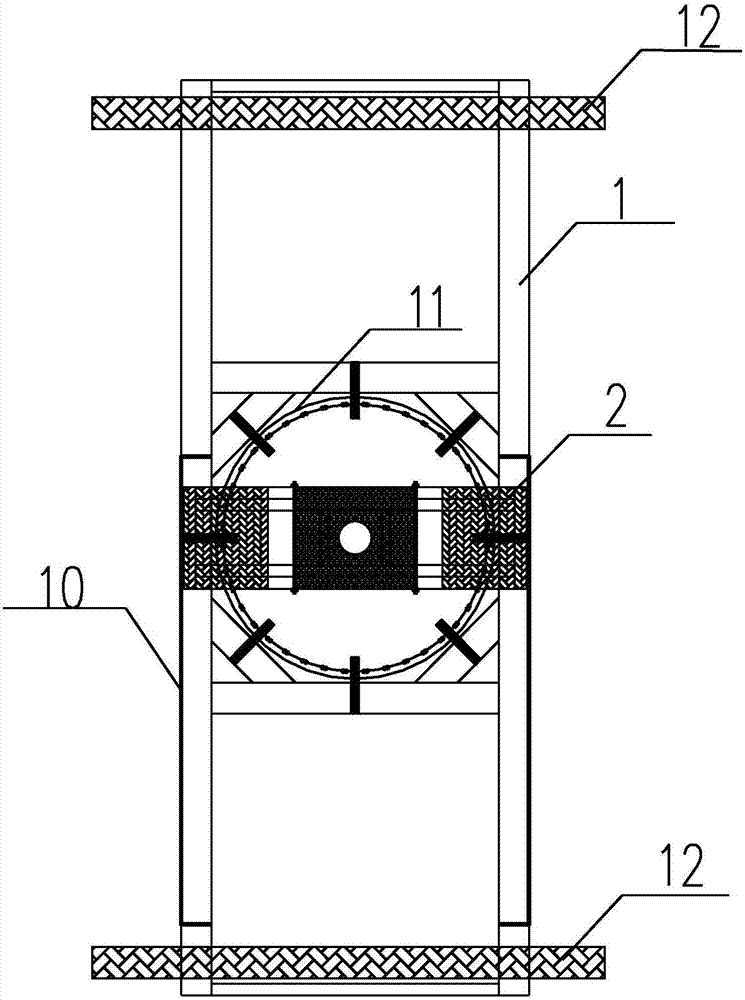

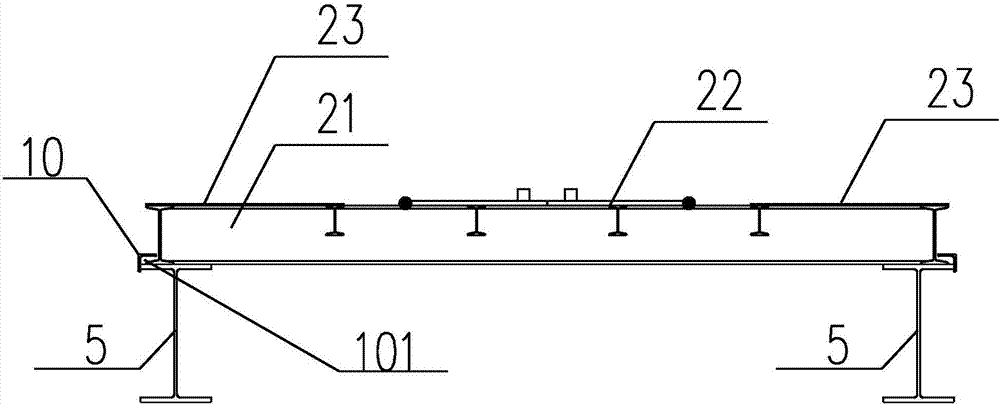

[0027] refer to Figure 1-7 As shown, a tool platform suitable for the positioning of cast-in-situ pile reinforcement cages and conduits includes a reinforcement cage positioning platform 1 and a conduit positioning platform 2. The reinforcement cage positioning platform 1 includes a frame main body and is arranged on the frame main body to support the steel bars. The movable support mechanism 4 of the cage 3, the frame main body includes a pair of frame longitudinal beams 5 arranged side by side at intervals, a pair of frame beams 6 arranged side by side and spaced apart between the two frame longitudinal beams 5, and connecting the frame longitudinal beams 5 and the frame The frame slanting beam 7 of the cross beam 6, the length of the frame longitudinal beam 5 exceeds the scope of the frame cross beam 6, and an extension arm 51 is formed outside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com