Karst cave penetrating type foundation pile ultimate bearing capacity model test system and test method

A technology of ultimate bearing capacity and model test, applied in the test of foundation structure, foundation structure engineering, construction, etc., it can solve the problem of undisclosed regional relationship of karst cave roof tensile failure, and has not yet elucidated the law and mechanism of karst cave stratum lateral friction loss. and other problems, to achieve the effect of easy test method, simple structure and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

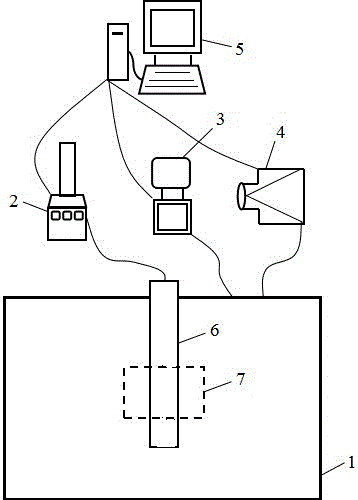

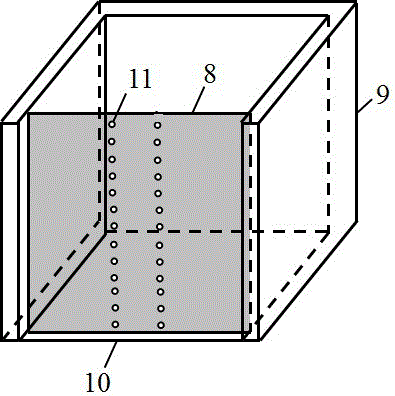

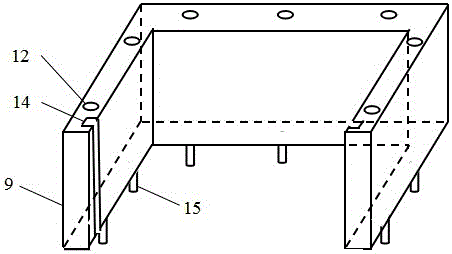

[0022] Such as figure 1 with Figure 5 As shown, it is an embodiment of a model test system and test method for the ultimate bearing capacity of a karst cave type foundation pile of the present invention, including a test box 1, a load control module 2, a data acquisition module, a foundation pile model 6, a karst cave model 7 and Analyze display module 5.

[0023] The pile model 6 and the karst cave model 7 are all arranged in the test box 1, and are fixed by the stratum model filled in the test box 1; the test box 1 is used to install the stratum, the pile model 6 and the karst cave model 7, and is a simulation experiment Provide the necessary model and simulation environment.

[0024] The four sides and the bottom surface of the inside of the test box 1 are covered with a smooth film for reducing surface friction;

[0025] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com