Novel wax scraper capable of adjusting squeezing and embracing force

A wax scraper, a new type of technology, applied in cleaning equipment, wellbore/well components, earth-moving drilling, etc. The effect of reducing wastage, improving wax removal efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

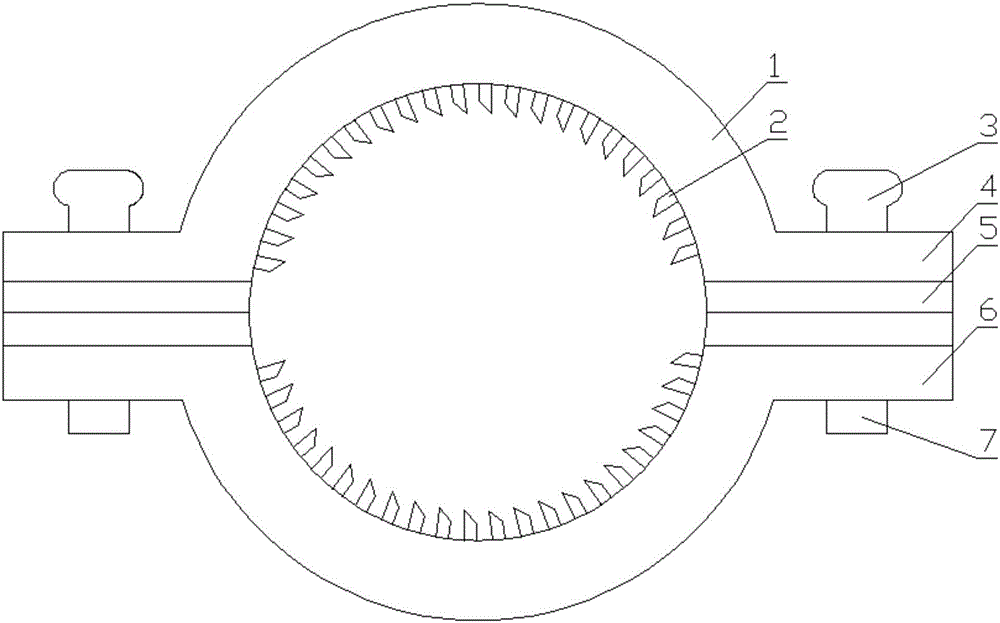

[0020] Such as figure 1 As shown, a new type of wax scraper for adjusting the squeezing force includes a squeeze ring 1, a blade 2, a bolt 3, an upper fixing bracket 4, a washer 5, and a lower fixing bracket 6. The squeeze ring 1 includes an upper squeeze ring The ring and the lower extrusion ring, the upper extrusion ring and the lower extrusion ring are all half ring structures, the upper extrusion ring and the lower extrusion ring are spliced to form a whole ring, and the inner sides of the upper extrusion ring and the lower extrusion ring are evenly arranged There are a plurality of blades 2; both ends of the upper extrusion ring are provided with upper fixing brackets 4, and both ends of the lower extrusion ring are provided with lower fixing brackets 6, and the corresponding upper fixing brackets 4 and lower fixing brackets 6 are connected by bolts 3 is fixed; a washer 5 is arranged between the corresponding upper fixing bracket 4 and the lower fixing bracket 6.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com