Gas turbine and aircraft engine combustor tail cylinder structure

A technology for aero-engines and gas turbines, applied in the directions of combustion chambers, combustion methods, combustion equipment, etc., can solve problems such as high price, achieve the effect of simple molding and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

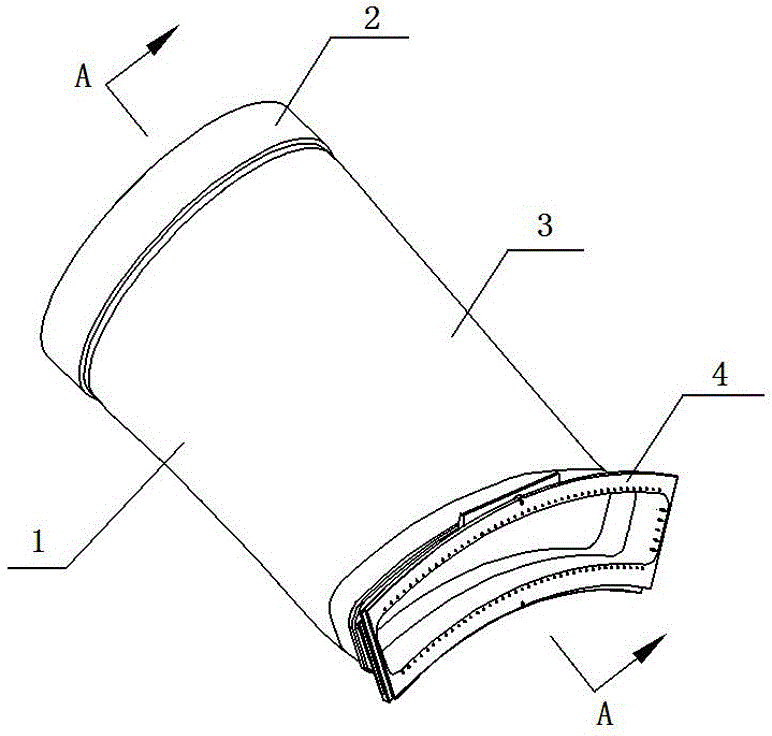

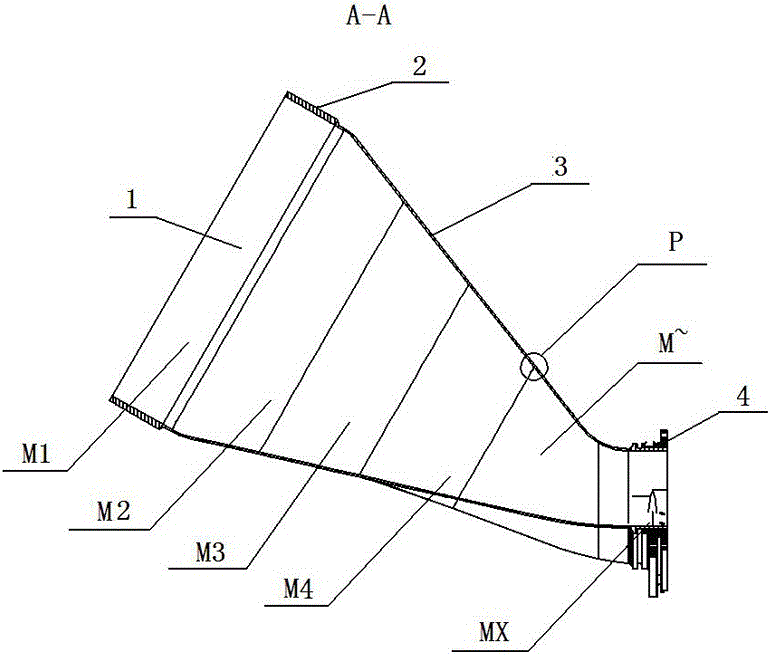

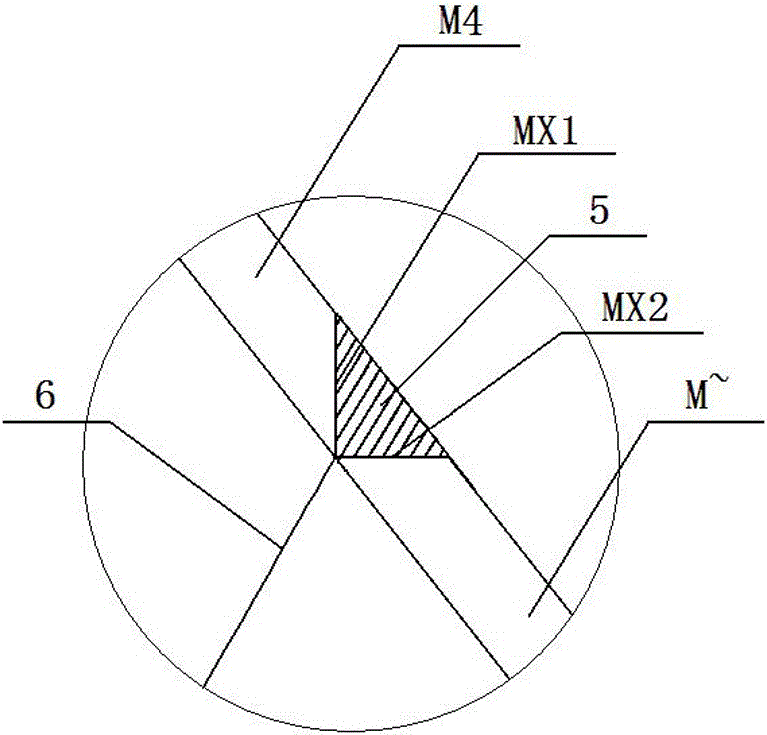

[0019] Such as Figure 1 to Figure 3 Shown: a gas turbine and aero-engine combustor transition piece 1 structure, including a support ring 2, a transition piece body 3 and an outlet flange 4; the support ring 2 is installed on the front end of the transition piece body 3; the outlet The flange 4 is installed at the rear end of the tailpiece body 3; the tailpiece body 3 is welded by six sections of superalloys with different high temperature resistance properties; and according to the distribution trend of the metal temperature, the part with higher temperature is the resistant The material with high high temperature performance, the part with lower temperature is the material with poor high temperature resistance. Six sections of high-temperature alloys with different high-temperature resistance properties are welded to form a complete transition tube body 3 as a whole. The superalloys of the six stages with different high temperature resistance properties are arranged in asc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com