Nuclear power station check valve testing device and test method

A technology of test device and check valve, which is applied in the direction of measuring the increase and decrease rate of the fluid, using liquid/vacuum degree to measure the liquid tightness, etc., can solve the problems of damage, increase of test cost, increase of equipment, etc., and reduce the reading error, reduce equipment damage and personal injury, and the effect of simple test work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

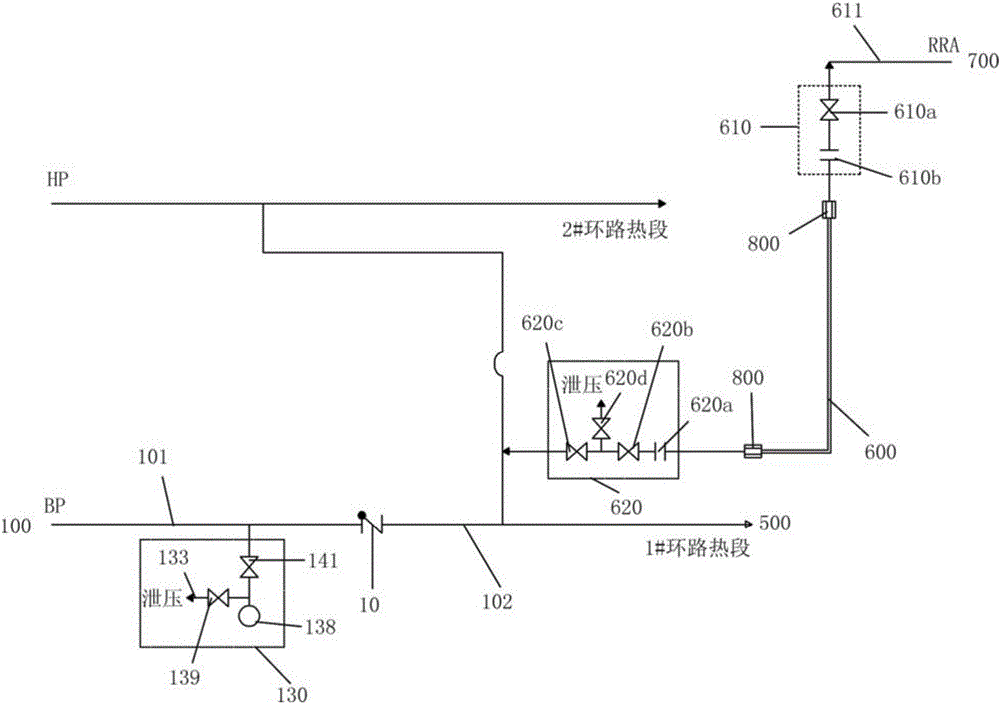

[0052] figure 1 It is a schematic connection diagram of the check valve test device, such as figure 1 As shown, the check valve test device includes:

[0053] The upstream pipeline 101 is used to connect the safety injection system 100;

[0054] a downstream pipeline 102 for connecting to the reactor coolant system 500;

[0055] The first check valve 10, connected between the upstream pipeline 101 and the downstream pipeline 102, also includes:

[0056] The high-pressure introduction component is connected between the primary circuit waste heat discharge system 700 and the downstream pipeline 102 of the first check valve 10, and is used to introduce the pressure of the primary circuit waste heat discharge system from high pressure and reduce the high pressure to the first The test pressure of a check valve 10 is delivered to said first check valve 10;

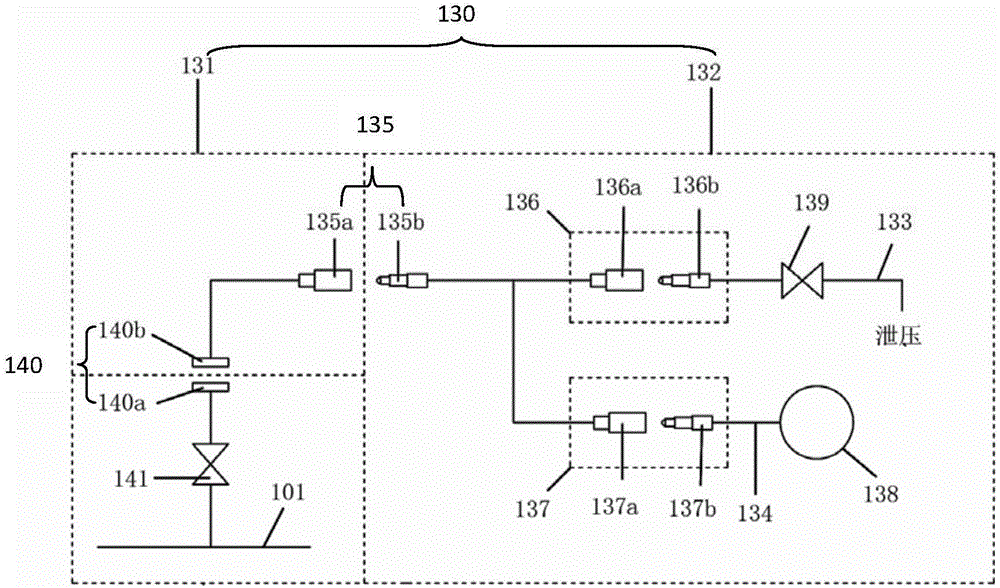

[0057] The pressure detecting member 130 is connected to the upstream pipeline 101 or the downstream pipeline 102 of the ...

Embodiment 2

[0091] The invention also provides a test method for the check valve of the nuclear power plant, which is used for the test of the sealing performance of the check valve of the safety injection pipeline of the nuclear power plant.

[0092] It should be noted that the check valve test can be divided into two basic methods, one is to pressurize the downstream of the check valve, isolate the upstream after pressure relief, and use a pressure gauge to monitor the rate of rise of the upstream pressure; After the downstream of the valve is pressurized, it is isolated, and the upstream is depressurized, and the downstream pressure drop rate is monitored with a pressure gauge.

[0093] combine figure 1 As shown, the following is a detailed description of the sealing test method for increasing the pressure at the downstream of the first check valve 10, and isolating after upstream pressure relief, using the pressure detection assembly 130 to detect whether the upstream pressure increases...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com