A greenhouse equipment fault detection system and method

A technology of equipment failure and detection method, which is applied in the direction of general control system, control/regulation system, program control, etc., and can solve problems such as failure of greenhouse environment regulation, failure to guarantee safe production in greenhouse, lack of on-site equipment failure analysis and safety protection system, etc. , to achieve the effect of improving the level of intelligent control and meeting the needs of crop growth

Active Publication Date: 2019-07-02

GUANGDONG PROVINCE MODERN AGRI EQUIP RES INST +1

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In order to solve the above technical problems, the present invention provides a greenhouse equipment fault detection system and method to solve the problem that the existing greenhouse equipment fault detection system and method cannot judge the real-time status and safety reliability of the on-site greenhouse environmental control equipment, which may lead to Greenhouse environmental regulation fails, greenhouse safety production cannot be guaranteed, lack of on-site equipment failure analysis and safety protection system

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

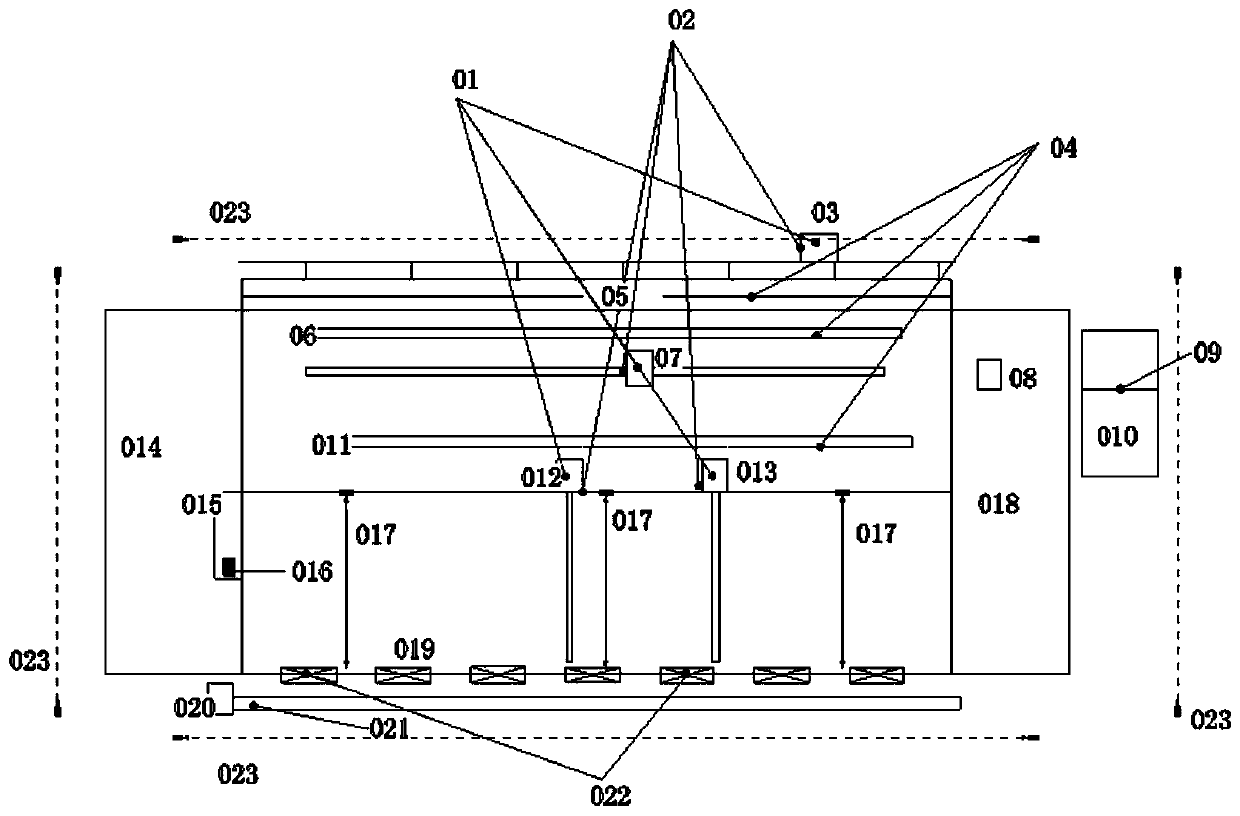

[0022] as attached figure 1 To attach image 3 shown

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

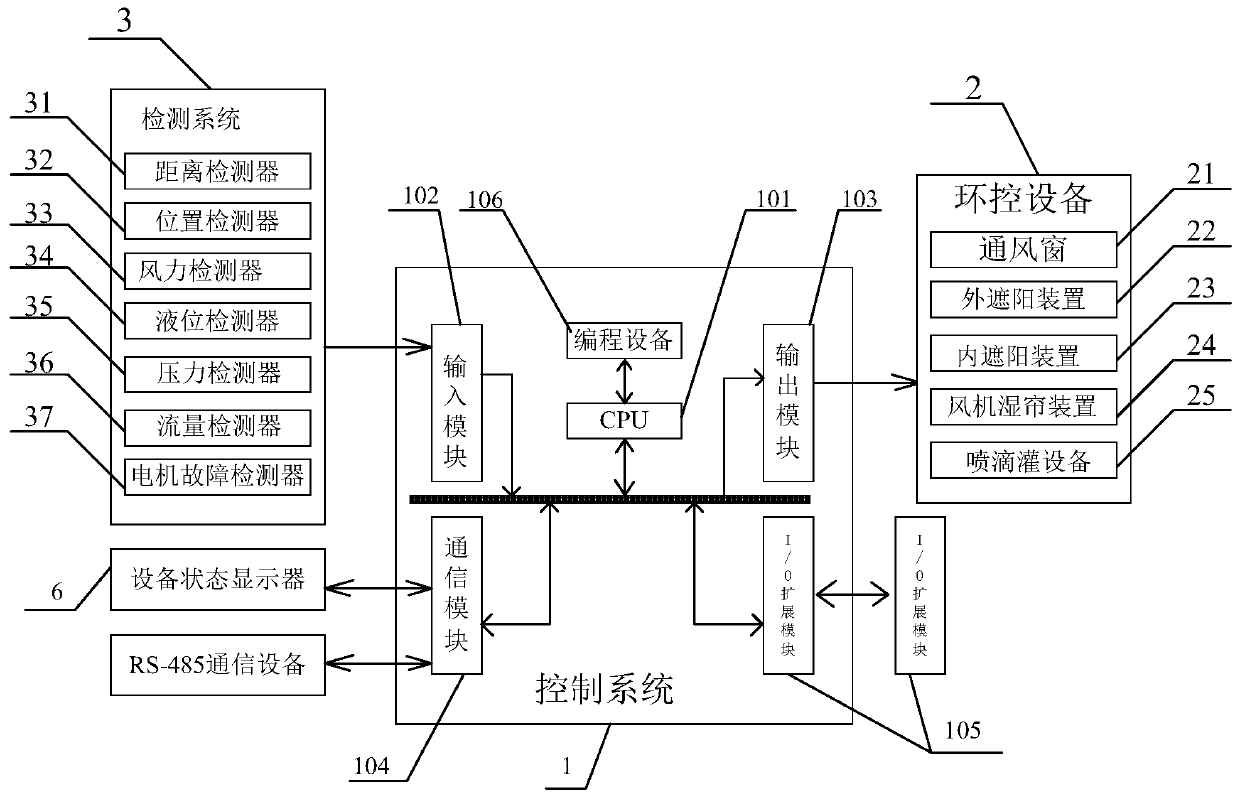

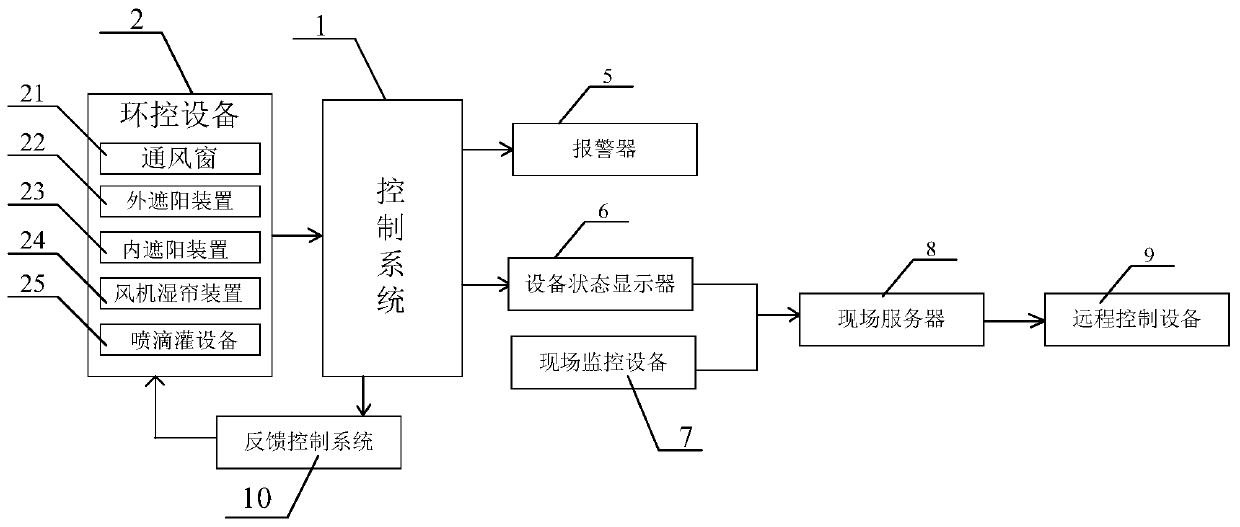

The invention provides a greenhouse equipment fault detection system and method, the system comprises a control system, environmental control equipment, a detection system, an alarm, an equipment real-time status display, on-site monitoring equipment, an on-site service, remote control equipment, a feedback control system and a safety protection device, the detection system is connected with the control system and the environmental control equipment, and it is good for detecting the control system and related equipment in real time and judging the operation condition of the greenhouse environmental control equipment. According to the invention, the arrangement of the detection system, the on-site server and the remote control equipment combines actual environmental data and equipment real-time status to regulate and control the environmental control equipment in the greenhouse according to the set environmental condition of the greenhouse, the whole environment of the greenhouse achieves the best status and satisfies crop growth requirements, the intelligent control level of greenhouse facilities is improved, and the system and the method is easy to popularize and apply.

Description

technical field [0001] The invention belongs to the technical field of agricultural facilities, and in particular relates to a greenhouse equipment fault detection system and method. Background technique [0002] In recent years, my country's protected horticulture industry has developed rapidly, and greenhouse planting has achieved certain results. Using the greenhouse environment control system can automatically adjust the temperature, humidity, light and other environmental parameters in the greenhouse as needed to meet the growth needs of greenhouse crops under different climatic conditions. , Improve greenhouse planting yield and labor efficiency. However, the existing greenhouse environment control system controls the operation of the greenhouse environment control equipment directly through the judgment of the on-site environmental data. Safe production cannot be guaranteed. In order to solve this problem, the existing technology is to add an on-site equipment monito...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G05B19/05

CPCG05B19/058G05B2219/14006

Inventor 刘霓红吴玉发陈金奇李惠玲李苇蒋先平魏楚伟程俊峰陈泽锋孔政沈林晨薛坤鹏黄健荣朱运天杨晓鹏

Owner GUANGDONG PROVINCE MODERN AGRI EQUIP RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com