Gypsum board powder grinding and conveying device

A conveying device and gypsum board technology, applied in grain processing and other directions, can solve the problems of powder blockage, poor working environment, bonding and other problems, and achieve the effect of not easy powder blockage and reasonable structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

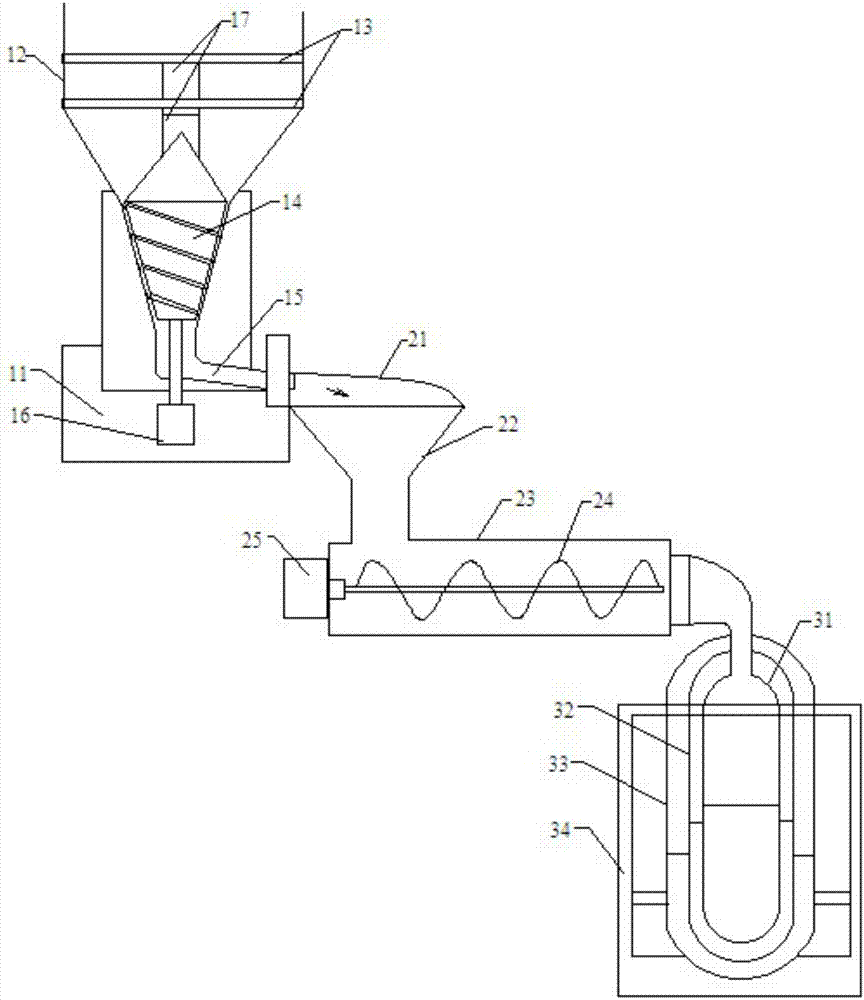

[0013] A kind of gypsum board powder grinding conveying device as shown in the accompanying drawing, this device comprises: grinder, the conveyer that is connected with grinder, the bag filter that is connected with conveyer, grinder includes: first bracket 11, The grinding shell 12 that is arranged on the first bracket 11 and has a conical cross section, the screen cloth 13 that is set on the upper part of the grinding shell 12, the rotary mill 14 that is set on the lower part of the grinding shell 12, and the Right inclined material outlet pipe 15, the bottom of the first bracket 11 is provided with a first motor 16 connected to the rotary mill 14, the top of the rotary mill 14 is connected to the center of the screen 13; the conveyor includes: a right inclined material outlet pipe 15 The feeding hopper 22 whose end is connected through the dust cover 21, the screw conveying shell 23 connected with the feeding hopper 22, the screw conveying rod 24 arranged in the conveying ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com