Metal-rubber composite flow channel of separator

A technology of metal rubber and composite flow channels, applied in the field of separators, can solve the problems of cell wall death, loss of activity, etc., achieve the effect of low cost, simple design, and improved cell survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

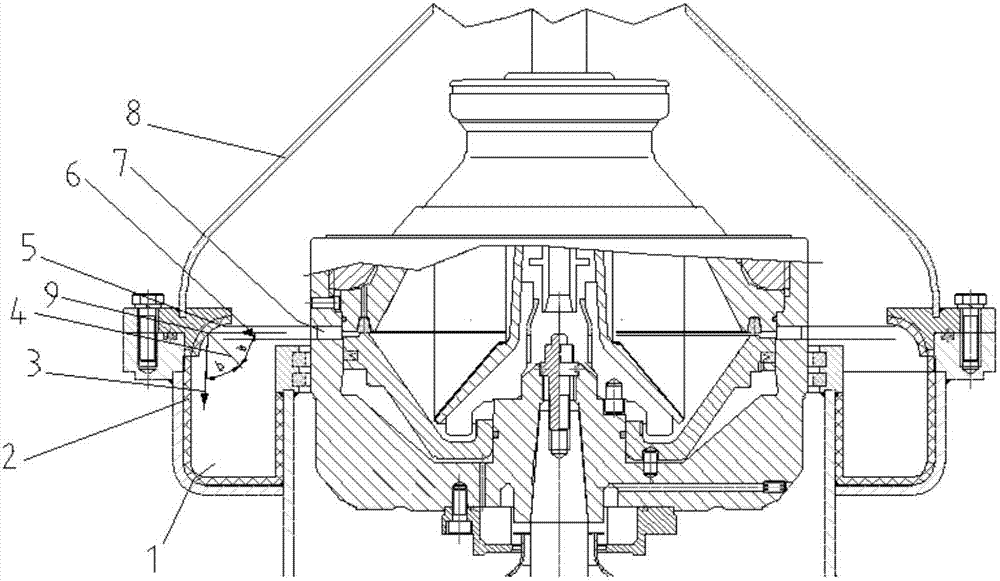

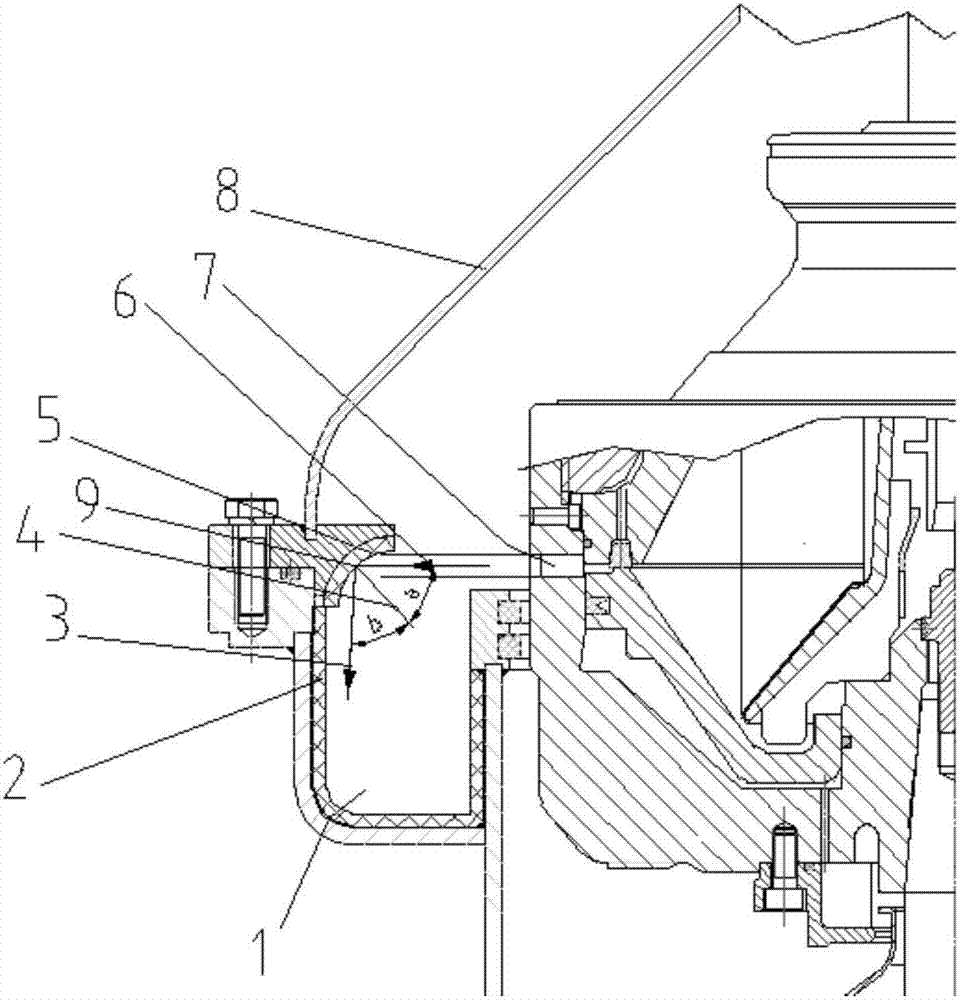

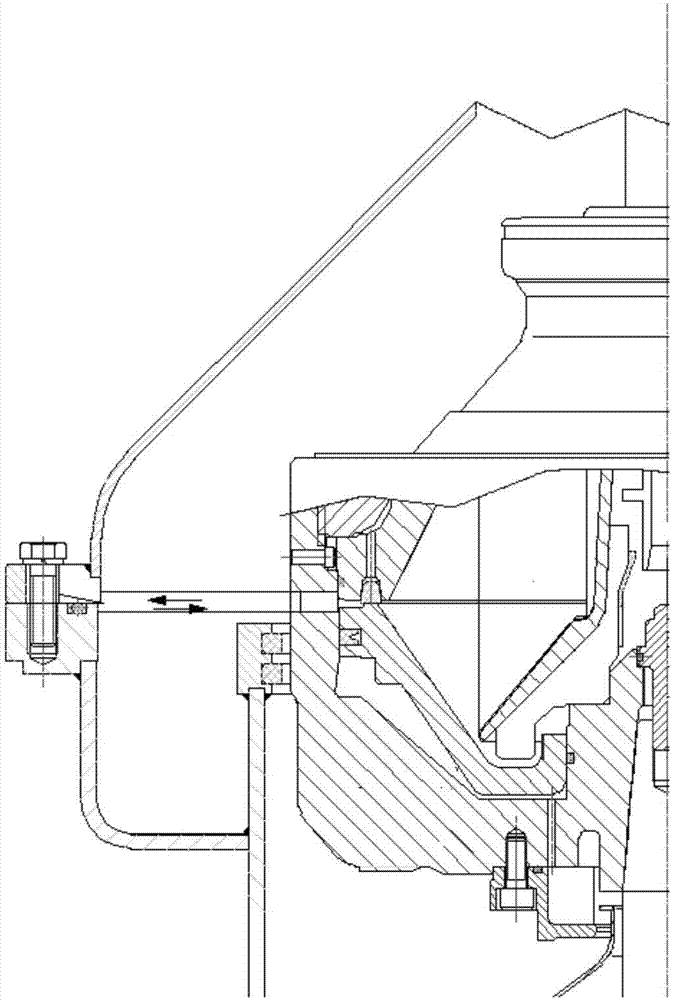

[0013] A kind of separator metal-rubber composite runner provided in this embodiment, such as Figure 1-2 Shown: comprise drum body and be arranged on drum body outer drum body frame 8; The inboard of described drum body frame 8 is provided with arc surface annular elastic part 5 near drum body slag discharge port 7; The inner wall of the slag discharge channel 1 at the bottom of the drum frame 8 is provided with an annular elastic lining 2 with a U-shaped longitudinal section. The arc-shaped annular elastic member 5 is integrated with the U-shaped annular elastic lining 2 .

[0014] The arc length of the longitudinal section of the arc-shaped annular elastic member 5 is 1 / 5˜1 / 4 of the circle.

[0015] The slag discharged from the slag outlet 7 is discharged along the horizontal direction 6 to the impact point 9 on the inner surface of the arc-shaped annular elastic member 5, and then rebounds to the slag discharge channel 1 along the direction 3; and the rebound angle is 60°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com