Five-shaft numerical control polishing machine

A polishing machine and machine base technology, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, grinding racks, etc., can solve the problems of 3D surface polishing of hardware products, inconsistent local colors of hardware products, and chamfering of hardware products Collapse and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

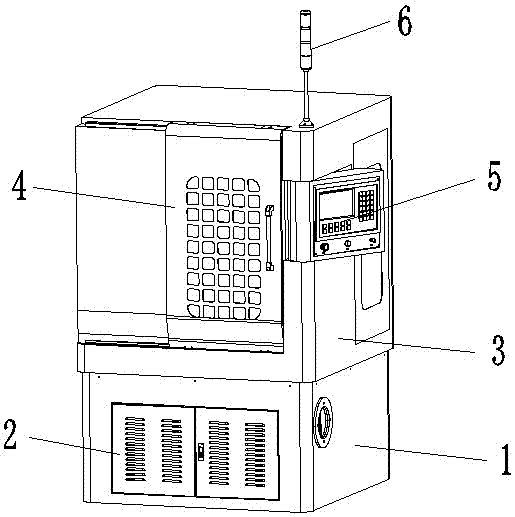

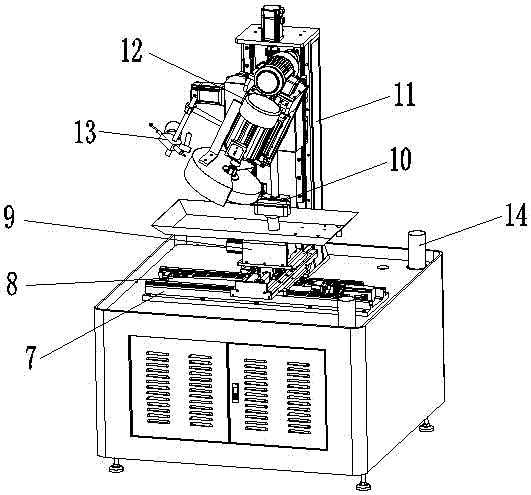

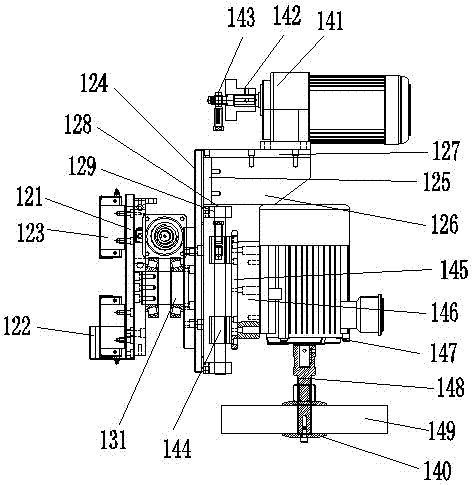

[0023] In this example, refer to Figure 1 to Figure 10 As shown, a five-axis CNC polishing machine of the present invention includes a machine base 1, an electric box 2 is arranged on the front side of the machine base 1, an organic cover 3 is arranged on the top of the machine base 1, and a sliding door is arranged on the front of the machine cover 3 4. An operation panel 5 is provided on the right side of the hood 3, and a warning light 6 is provided on the top surface of the hood 3, and a Y-axis servo module mechanism 7 is provided on the top surface of the machine base 1 inside the hood 3. An X-axis servo module mechanism 8 is arranged above the axis servo module mechanism 7, a Z-axis rotation mechanism 9 is arranged above the X-axis servo module mechanism 8, and a jig 10 is arranged above the Z-axis rotation mechanism 9; The rear side of the servo module mechanism 7 is vertically provided with a column mechanism 11, the front side of the column mechanism 11 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com