Elevator braking device and lifting mechanism thereof

A technology of lifting mechanism and elevator speed limiter, which is applied in the field of elevators, can solve the problems of potential safety hazards and difficulty in ensuring safe braking of the car, and achieve the effects of improving safety, simple structure, and preventing loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

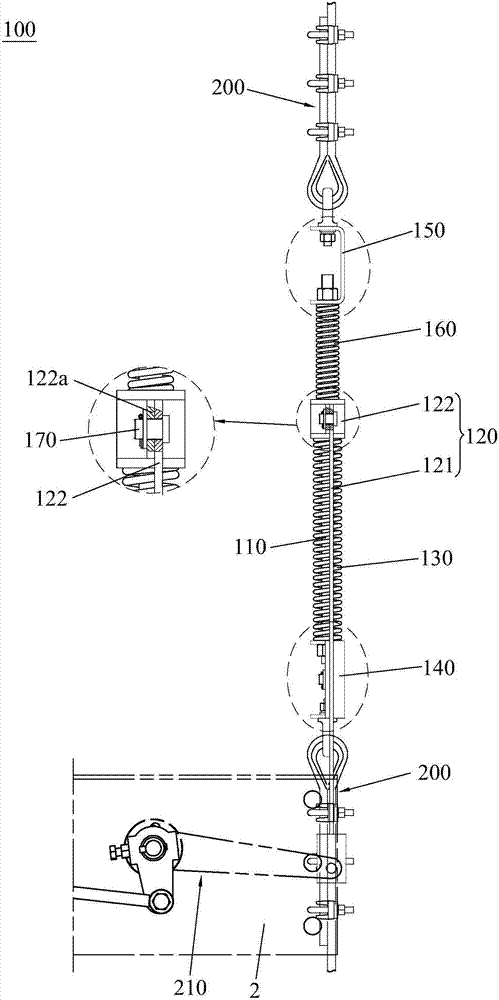

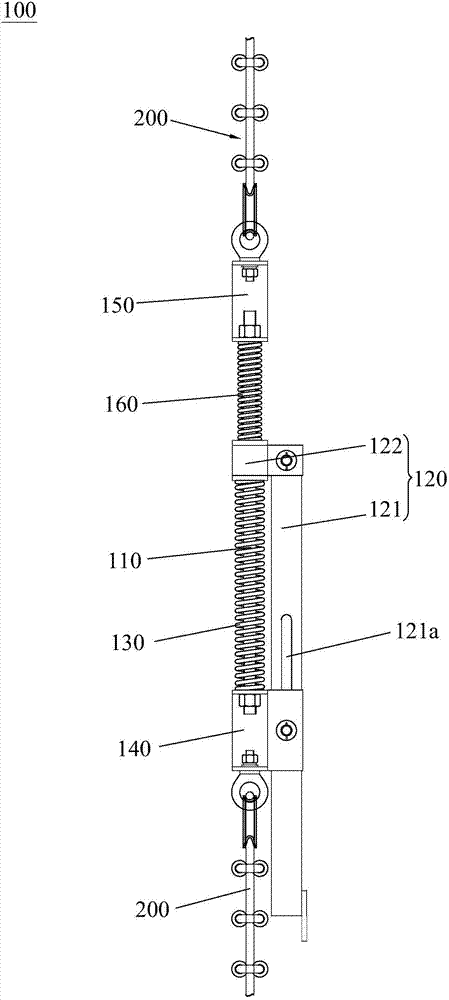

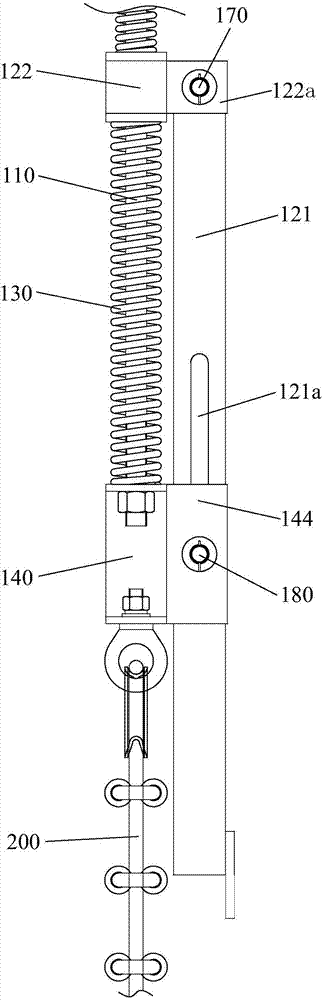

[0026] combine first Figure 1-2 , 6, the pulling mechanism 100 provided by the present invention is suitable for the speed governor 10 with automatic reset function, so that the steel wire rope 200 connected to the speed governor 10 is connected to the elevator car through the pulling mechanism 100. Safety gear device 210 on the car.

[0027] Concrete combination figure 1 , 6 As shown, the upper end of the wire rope 200 bypasses the overspeed governor 10, the lower end of the wire rope 200 bypasses the tensioning device 20, and the two ends of the wire rope 200 are connected by the pulling mechanism 100. Therefore, the wire rope 200 and the pulling mechanism 100 form a A ring-shaped wrapping unit 30, and the lifting mechanism 100 is also connected to the safety gear device 210 on the elevator car 2. The setting of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com