Coke tower detection lifting device and coke tower detection system

A technology for coke towers and lifting platforms, which is applied in the direction of hoisting devices, lifting equipment safety devices, lifting frames, etc., can solve the problems of concentrated workload, high difficulty, and short construction period, so as to save time, meet the needs of use, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

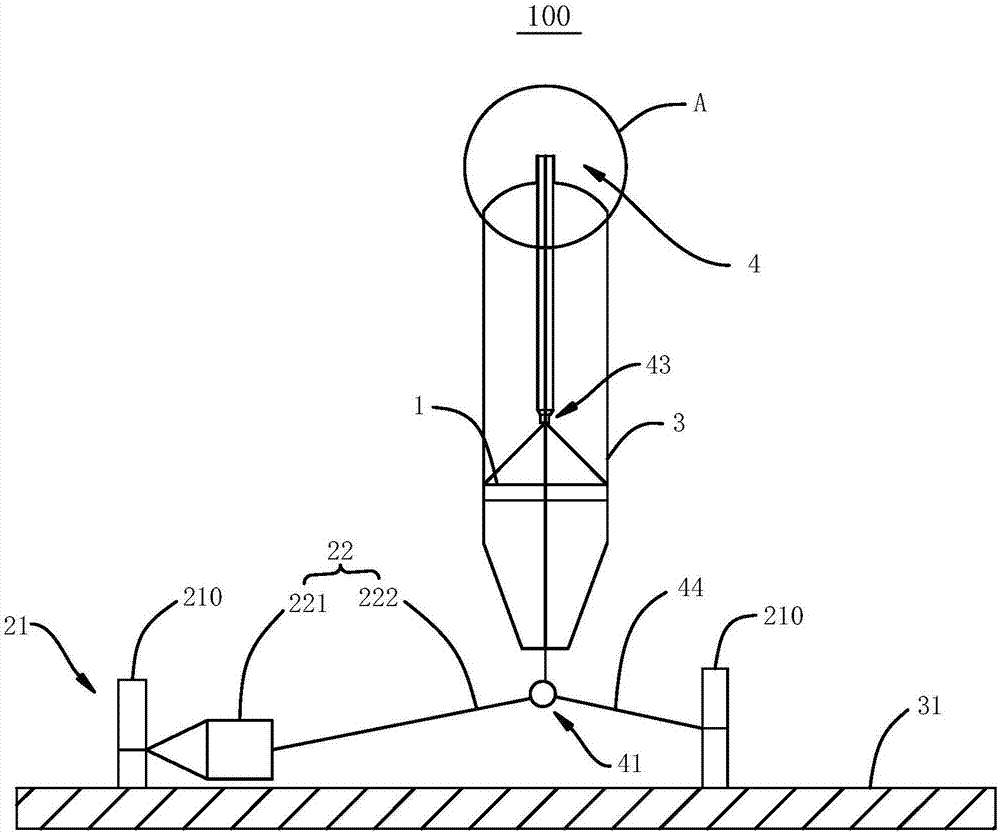

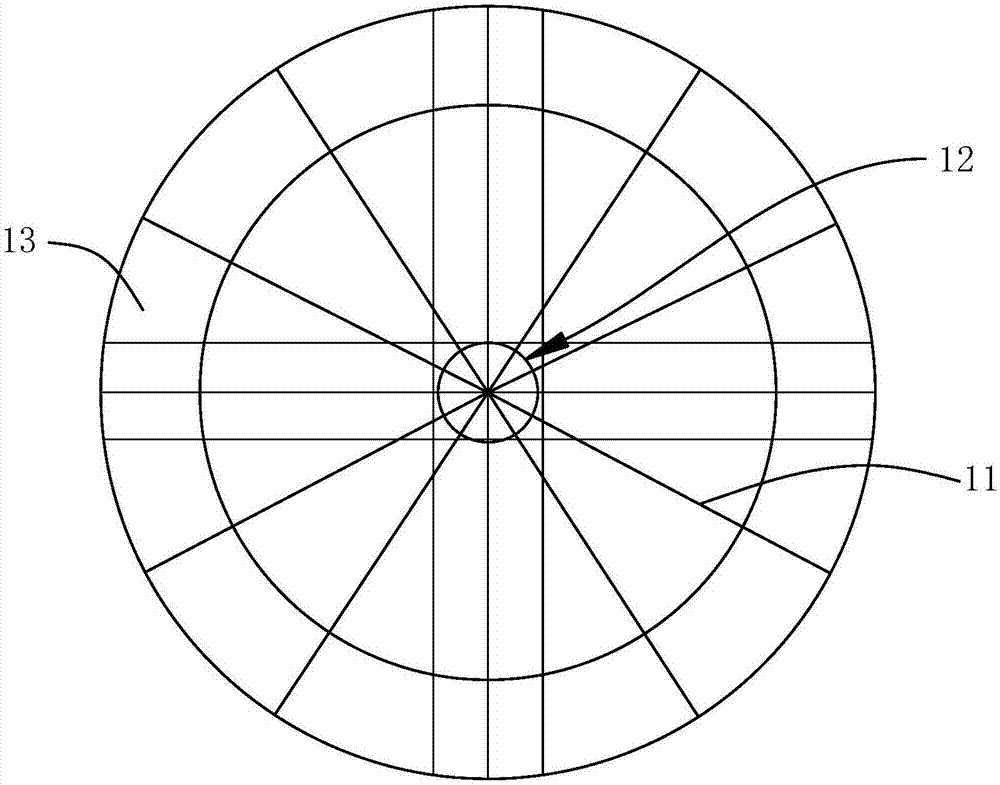

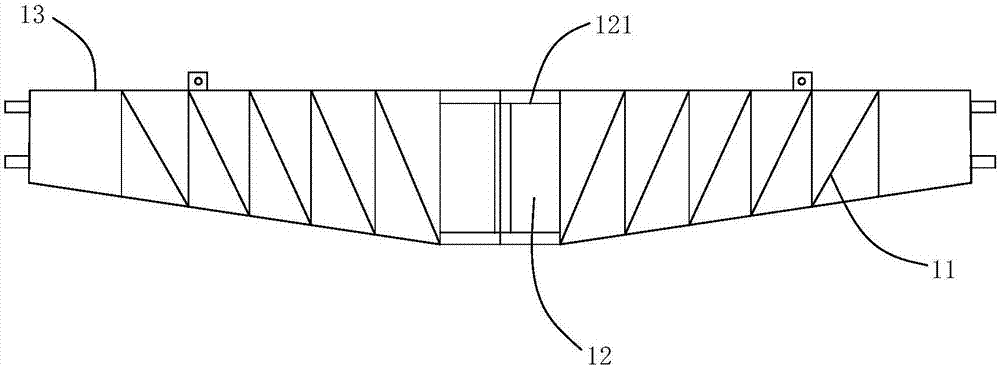

[0035] Please refer to figure 1 , this embodiment provides a coke drum detection and lifting device 100, including a lifting platform 1 and a lifting mechanism.

[0036] In this embodiment, the lifting platform 1 is slidably arranged in the coke drum 3, the edge of the lifting platform 1 is connected with the coke drum 3, and the lifting mechanism includes a fixed assembly 21 and a traction assembly 22, and the fixed assembly 21 is fixed on the coke drum frame platform 31. The two ends of the traction assembly 22 are respectively connected with the fixed assembly 21 and the lifting platform 1. The traction assembly 22 is used to drag the lifting platform 1 to reciprocate along the height direction of the coke tower 3, so that the operator can quickly and safely move inside the coke tower 3. lift operation.

[0037] The specific structure and mutual positional relationship of each component of the coke drum detection and lifting device 100 will be described in detail below.

...

no. 2 example

[0059] This embodiment provides a coke drum detection system, including the coke drum detection and lifting device 100 provided in the first embodiment.

[0060] During the inspection of the coke tower 3, the operator needs to move up and down inside the coke tower 3 to find the gaps in the inner wall of the coke tower 3. The use of the coke tower inspection lifting device 100 improves the work efficiency of the operator, shortens the construction preparation time, and shortens the construction period. Short and safe to operate.

[0061] In summary, the present invention provides a coke tower detection and lifting device 100 and a coke tower detection system. The coke tower detection and lifting device 100 has a simple structure, convenient assembly, and high safety, and is convenient for operators to carry out in the coke drum 3. Inspection construction.

[0062] The coke tower detection system using the coke drum detection and lifting device 100 improves the work efficiency...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com