Application of carbon tube film in anisotropic polymer preparing

An anisotropic, carbon tube film technology, which is applied in the field of preparation of polymer/carbon tube composite film materials, can solve problems such as waste of resources, and achieve the effects of low filler dosage and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Carbon tube membrane modification: Add 0.01 mol / L p-phenylenediamine solution dropwise to 0.1 mol / L HCl solution at a volume ratio of 1:1 to obtain an acidic p-phenylenediamine solution. At 0°C, add 0.01 mol / L sodium nitrite solution dropwise to the acidic p-phenylenediamine solution at a molar mass ratio of 1:1 for reaction to obtain a dark red diazonium salt solution. At room temperature, the carbon tube membrane was placed in a diazonium salt solution and reacted for 12 hours. The sample was taken out and washed repeatedly with deionized water, ethanol and acetone to obtain a modified carbon tube membrane.

[0024] (2) Using the modified carbon tube film as the substrate, compounding the polyurethane and the carbon tube film, annealing at a stepwise temperature rise within the range of 50-400° C., to obtain a polyurethane / carbon tube composite thin film material.

Embodiment 2

[0026](1) Carbon tube membrane modification: Add 0.5 mol / L p-phenylenediamine solution dropwise to 0.1 mol / L HCl solution at a volume ratio of 1:1 to obtain an acidic p-phenylenediamine solution. At 0°C, add 0.5 mol / L sodium nitrite solution dropwise to the acidic p-phenylenediamine solution at a molar mass ratio of 1:1 for reaction to obtain a dark red diazonium salt solution. At room temperature, the carbon tube membrane was placed in a diazonium salt solution and reacted for 20 h. The sample was taken out and washed repeatedly with deionized water, ethanol and acetone to obtain a modified carbon tube membrane.

[0027] (2) Using the modified carbon tube film as the substrate, compounding the polyimide acid and the carbon tube film, and annealing in the range of 50-400° C. to obtain the polyimide / carbon tube composite thin film material.

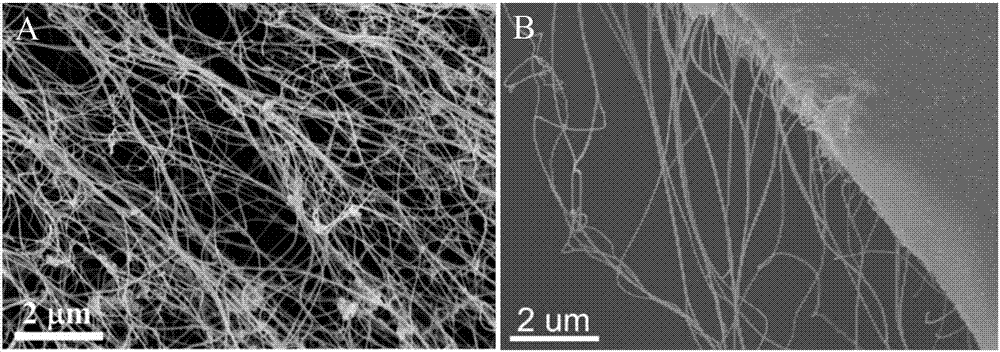

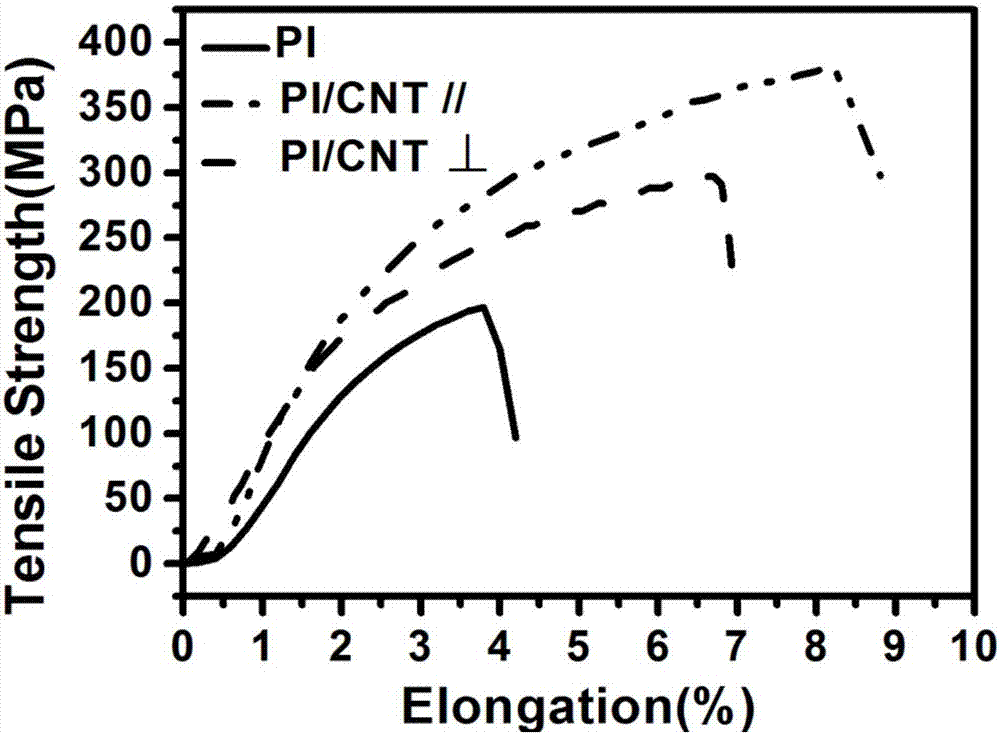

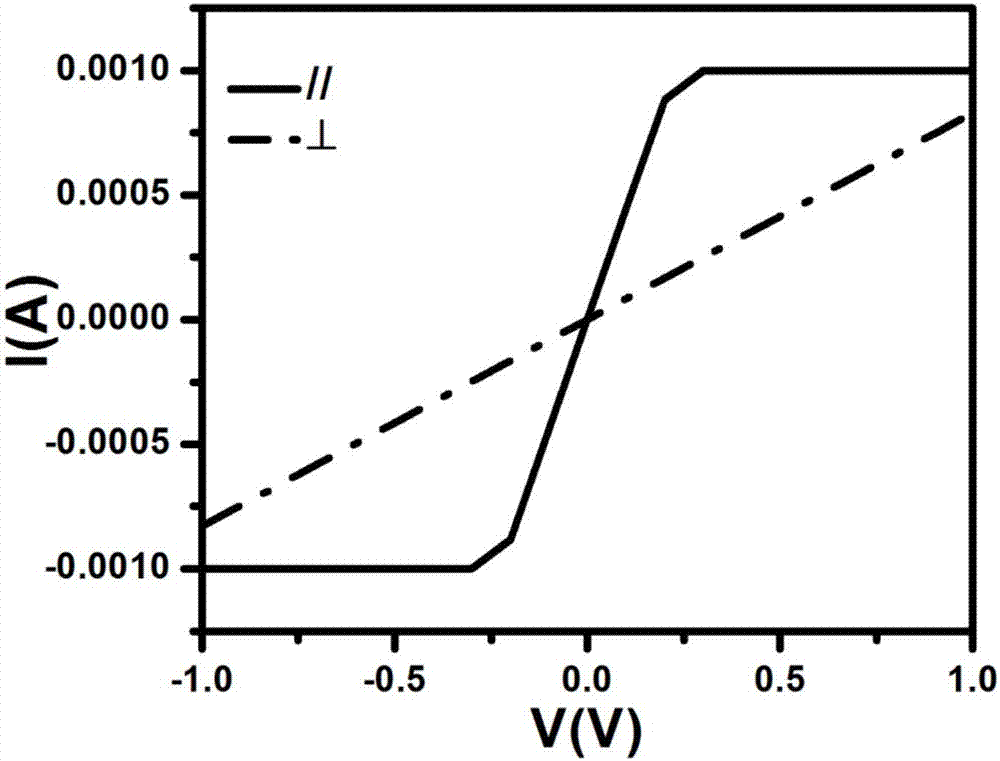

[0028] figure 1 SEM images of carbon tube film and polyimide / carbon tube composite film. from figure 1 (A) It can be seen that the ca...

Embodiment 3

[0032] (1) Carbon tube membrane modification: Add 0.01 mol / L p-phenylenediamine solution dropwise to 0.1 mol / L HCl solution at a volume ratio of 1:1 to obtain an acidic p-phenylenediamine solution. At 0°C, add 0.01 mol / L sodium nitrite solution dropwise to the acidic p-phenylenediamine solution at a molar mass ratio of 1:1 for reaction to obtain a dark red diazonium salt solution. At room temperature, the carbon tube membrane was placed in a diazonium salt solution and reacted for 12 hours. The sample was taken out and washed repeatedly with deionized water, ethanol and acetone to obtain a modified carbon tube membrane.

[0033] (2) Using the modified carbon tube film as a substrate, compounding polystyrene and carbon tube film, and annealing at a stepwise temperature rise within the range of 50-400° C., to obtain a polystyrene / carbon tube composite thin film material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com