Buckling restraint support for pieces of corrugated web H-shaped steel

A corrugated web and buckling restraint technology is applied to the buckling restrained support of corrugated web H-shaped steel. It can solve problems such as diversified design requirements, and achieve the effect of high self-stability coefficient, increased cross-section utilization rate, and reduced burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

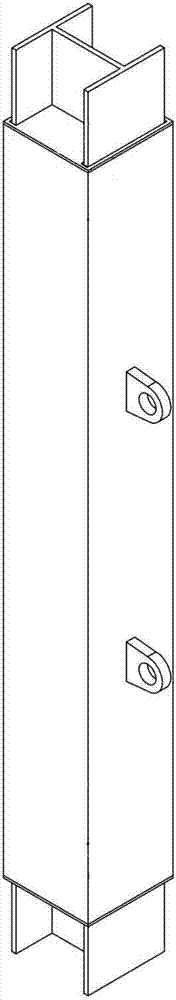

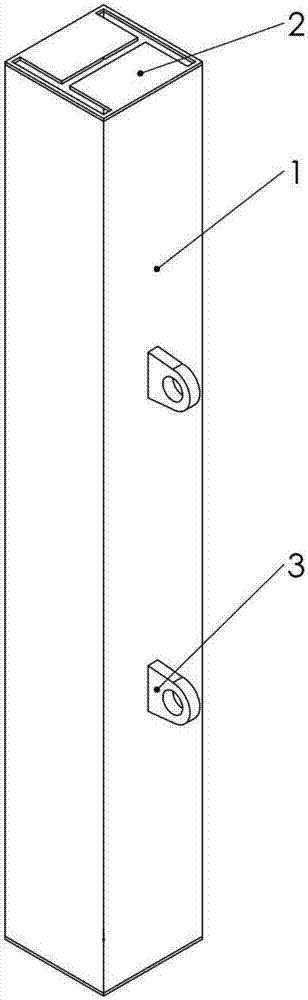

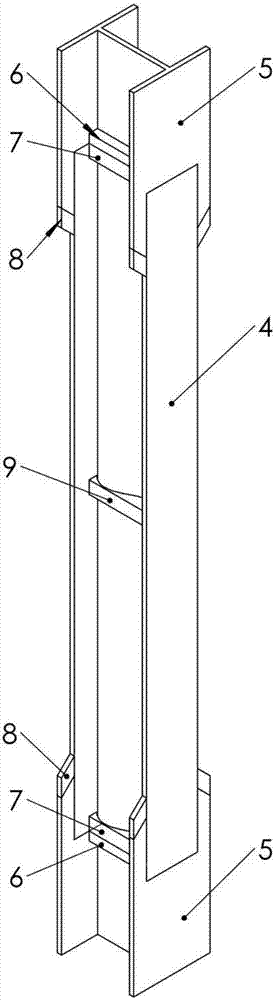

[0041] The present invention is a corrugated web H-shaped steel buckling-constrained support, which is a corrugated web H-shaped steel energy-dissipating core buckling-constrained support for building energy dissipation and shock absorption, such as figure 1 with Figure 4 As shown, it includes core unit, restraint unit and sliding mechanism unit.

[0042] The core unit, i.e. core material, such as image 3 with Figure 4 As shown, including corrugated web H-shaped steel 4 and flat web H-shaped steel 5. The corrugated web H-shaped steel 4 and the flat web H-shaped steel 4 used for cross-section reinforcement at both ends are connected as a whole through connecting plates. The corrugated web H-shaped steel 4 adopts steel with low yield point to ensure that the buckling-constrained support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com