Vertical hoisting system for glass boards of special-shaped curtain wall

A glass and plate technology, applied in the field of glass plate vertical lifting system, can solve the problems of difficulty and high lifting cost, and achieve the effect of improving installation efficiency, solving lifting difficulties, and convenient and quick installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

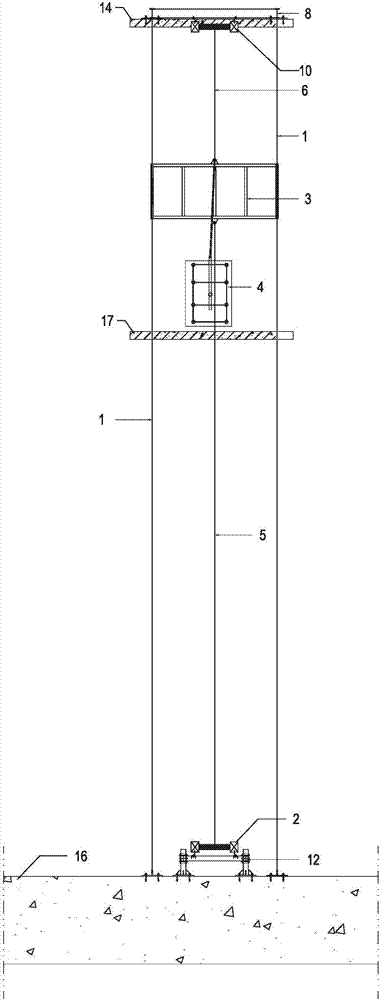

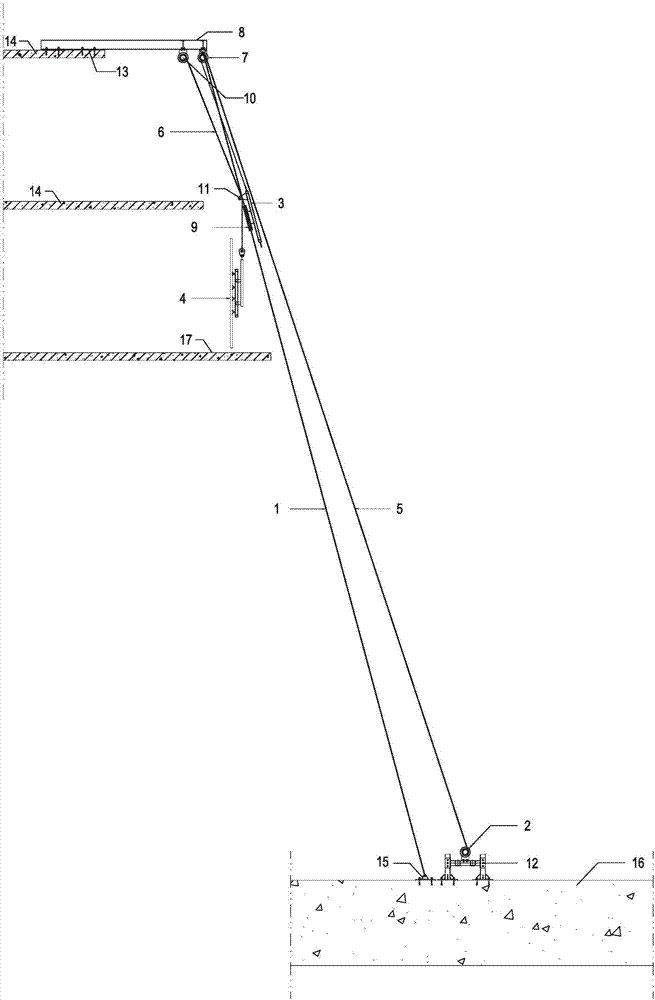

[0011] The vertical lifting system for the glass plate used in the special-shaped curtain wall of the present invention is as follows: figure 1 with figure 2 As shown, a fixed steel frame 8 is mounted on a floor 14 above the hoisting floor 17 where the plate installation position on the curtain wall to be constructed is cantilevered by bolts and buried plates 13, and a top pulley 7 is fixedly installed on the cantilevered end of the fixed steel frame 8. And adjust the hoist 10, a cableway is installed obliquely between the fixed steel frame 8 and the ground 16, the cableway is composed of two parallel cableway steel wire ropes 1, one end of the cableway steel rope 1 is fixed by the ear plate 15 and the embedded part of the ground 16, and the other end is passed through The lug plate is fixed to the fixed steel frame 8, and the cableway should be properly tensioned to a certain prestress, so that it has a certain rigidity to support the lifting of the glass plate 4 for transpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com