A variable-diameter hydraulic cutter for cutting casings with different diameters using multi-head screw drive

A screw drive, multi-head technology, used in wellbore/well components, earth-moving drilling and other directions, can solve the problems of inability to accurately control the opening angle of the cutter, low casing cutting efficiency, and easy cutter wear, etc., to improve cutting Efficiency, shorten the construction period, and facilitate the effect of smooth discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

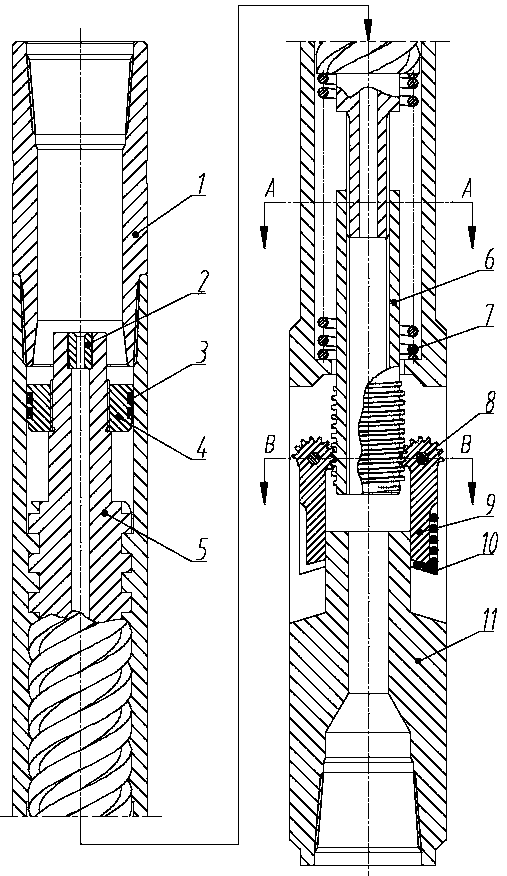

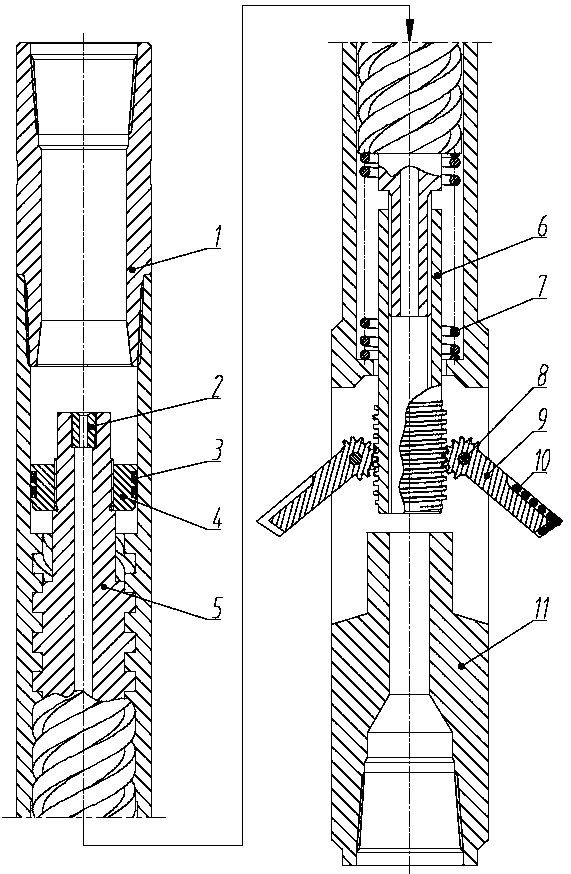

[0016] Below in conjunction with figure, the present invention will be further described:

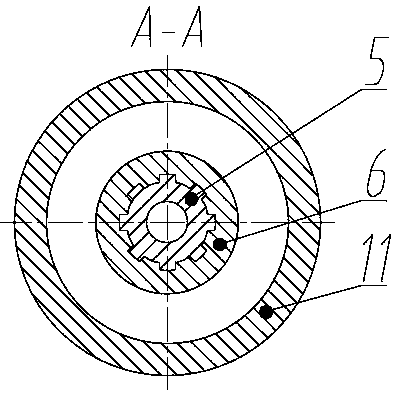

[0017] According to the drawings, the variable-diameter hydraulic cutter for cutting casings with different diameters is realized by multi-head screw transmission, which consists of an upper joint 1, a nozzle 2, a sealing ring 3, a piston 4, a mandrel 5, a worm 6, a spring 7, and a hinge Composed of pin 8, cutter 9, hard alloy teeth 10, and housing 11, it is characterized in that: the upper joint 1 and the hydraulic cutter housing 11 are connected by threads; the nozzle 2 is installed on the mandrel by thread 5, the piston 4 and the mandrel 5 are connected by threads, and the seal between the piston 4 and the housing 11 is realized by the sealing ring 3; the mandrel 5 has an axial through hole inside, and the outer surface of the mandrel 5 has a spiral groove , the inner surface of the matching part of the housing 11 and the mandrel 5 has an inner spiral groove, and the mandrel 5 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com