Flap valve head loss experiment testing system and using method thereof

A testing system and water head technology, which is applied in the direction of mechanical valve testing, etc., can solve the problems of inaccurate calculation of water head loss coefficient and complicated water flow movement at the valve outlet, so as to improve the accuracy and efficiency of experiments, facilitate movement and assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings.

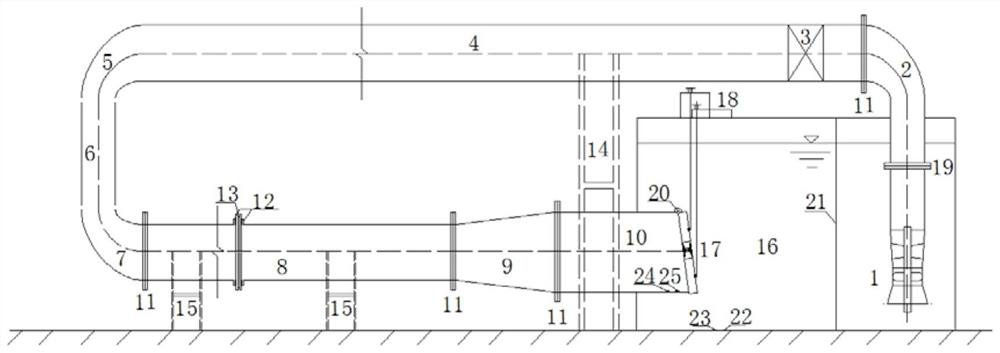

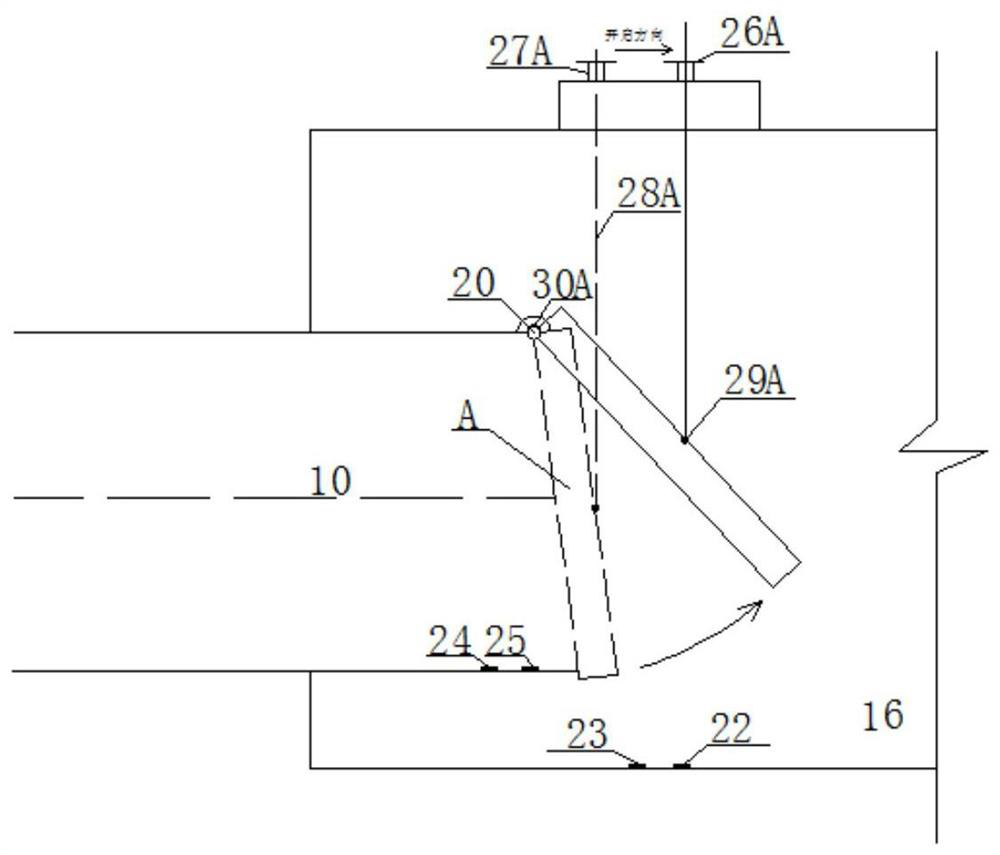

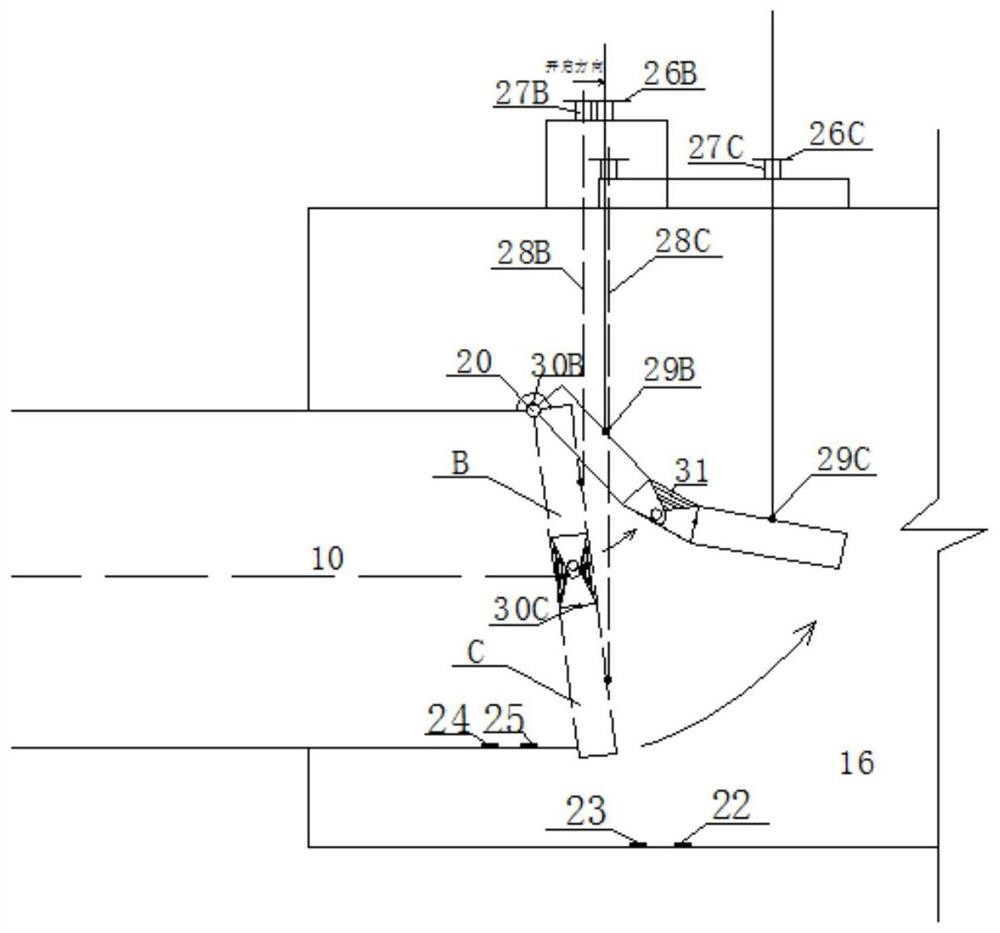

[0049] Such as Figure 1 to Figure 7 As shown, a kind of valve head loss experimental testing system and its using method of the present invention comprise:

[0050] Single beat gate A, upper beat gate B of double beat gates, lower beat gate C of double beat gates, cross-flow submersible pump 1, PVC right-angle diffusion elbow Ⅰ 2, control gate valve 3, PVC horizontal straight pipe 4, PVC Right-angle shrinking elbow 5, PVC vertical straight pipe 6, PVC right-angle diffuser elbow II 7, organic glass horizontal straight tube 8, organic glass gradient tube 9, transparent plastic tube 10, steady flow plate 11, pressure measuring hole 12, standard hole Plate 13, "H" type fixed bracket Ⅰ14, "H" type fixed bracket II 15, transparent plastic box 16, flap door body 17, flap door opening angle control device 18, expansion joint 19, rigid door shaft 20, flow barrier 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com