Sealing assembly adopting non-contact mechanical sealing and used for preventing lubricating oil leakage

A mechanical seal, non-contact technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve problems such as leakage, and achieve the effect of long service life, compact structure and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

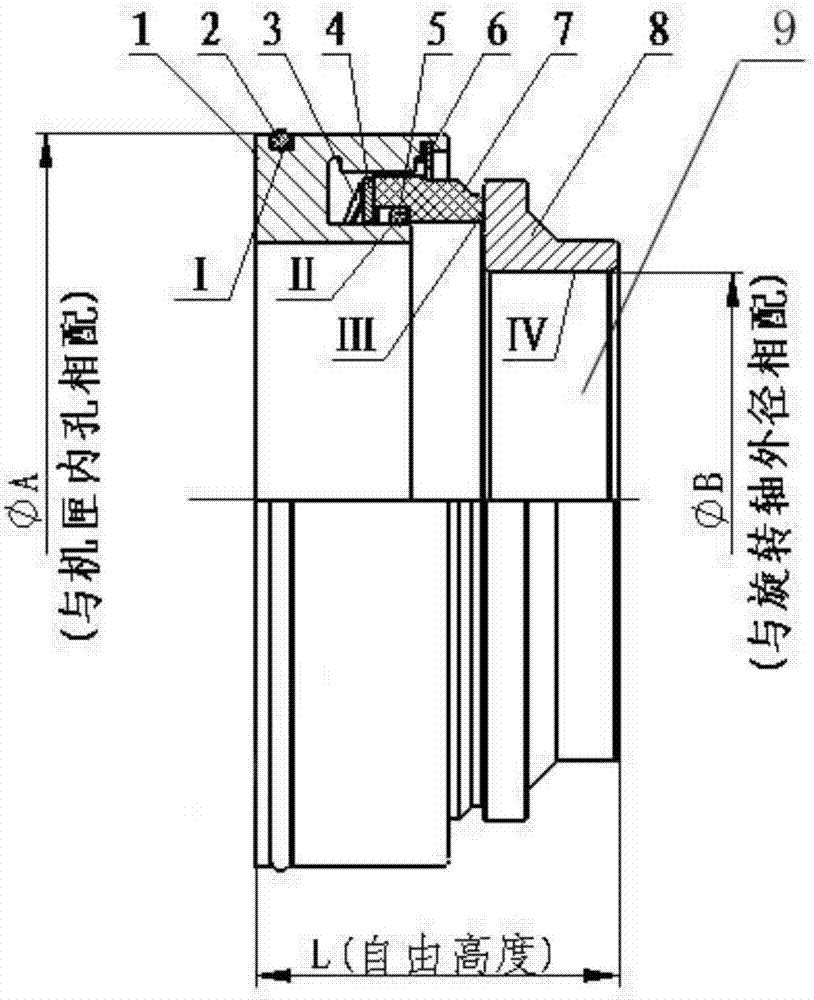

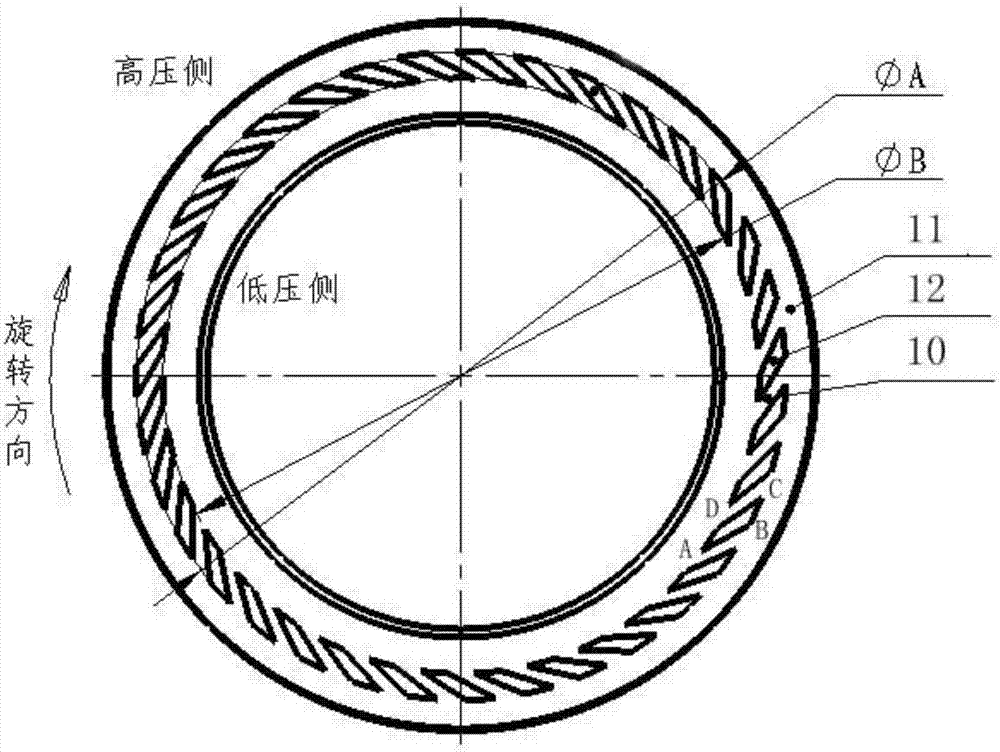

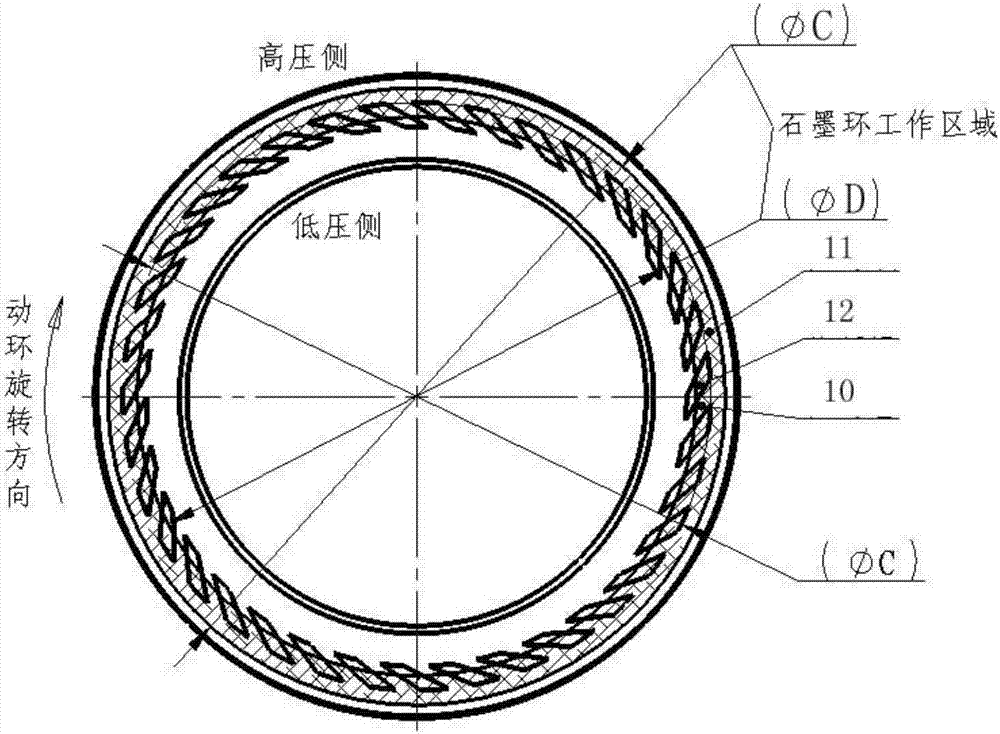

[0025] Such as Figure 1-3 As shown, the present invention is a non-contact mechanical seal and a sealing assembly for preventing lubricating oil leakage, which is applied to a pumping dynamic seal for sealing mineral oil or lubricating oil. The seal is mainly composed of a static ring assembly and a dynamic The ring consists of two parts. The product structure and main dimensions are shown in the following 1. It consists of a static ring cover 1, an O-ring seal 2, a wave spring 3, a gasket 4, an O-ring seal 5, a collar 6, a graphite ring 7 and a moving ring 8. attached figure 2 Among them, the outer part of ΦA on the working end surface of the dynamic sealing ring 8 is the sealing dam 11 , and the parts of the two hydrodynamic pressure grooves 12 are the sealing weir 10 . The structural shape of the fluid dynamic pressure groove 12 is determined according to the diameter of the working end surface of the sealed graphite static ring 7 and the actual situation. The inner sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com