Planar torsional micro sensor for measurement of strong magnetic field

A torsional micro-sensor technology, applied in the size/direction of the magnetic field, measuring device, measuring magnetic variables, etc., can solve the problems of reduced sensor quality factor, poor radiation resistance, and large temperature dependence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A planar torsion microsensor for measuring a strong magnetic field includes a substrate, a sensor body and a cover that are sequentially connected.

[0051] The substrate is a single-sided polished wafer 5 with a thickness of 500 um, a cavity with a depth of 1.2 um is provided on the polished side, and a first silicon oxide layer 6 is provided on the entire polished surface with the cavity;

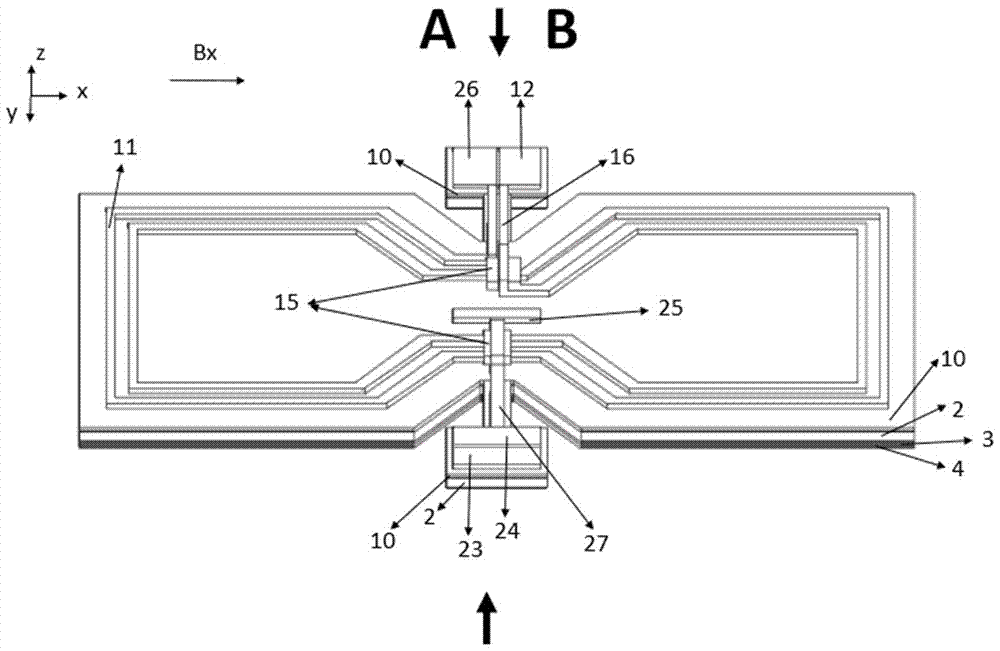

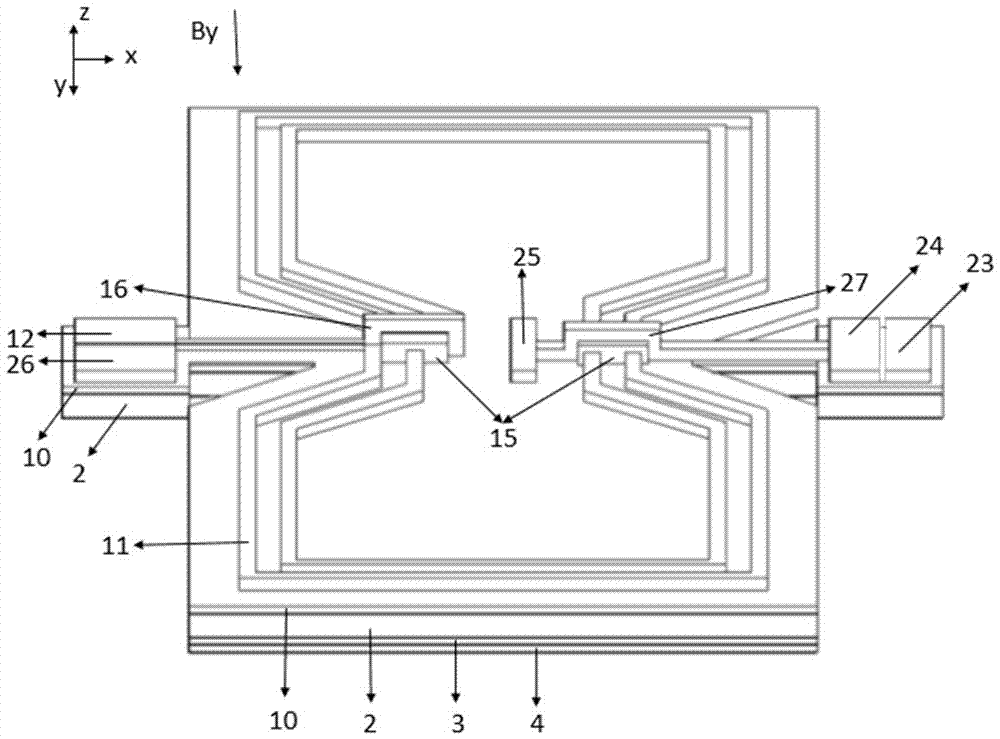

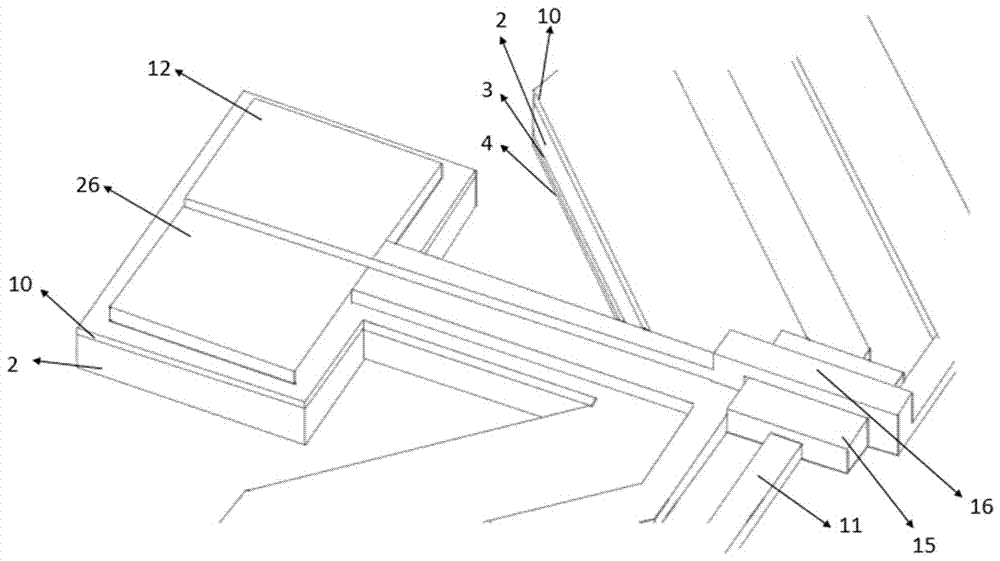

[0052] see figure 1 , the sensor body is prepared on the basis of SOI wafer 1, and the sensor body is divided into three parts: the coil electrode anchor area, the torsion plane, and the capacitive electrode anchor area; the length direction of the torsion plane is the X direction, the width direction is the Y direction, and the torsion plane The two sides of the middle part in the Y direction are respectively concave inward, the coil electrode anchor area is located outside one side of the Y direction in the middle of the torsion plane; the capacitive electrode anchor area is loca...

Embodiment 2

[0064] The steps to prepare the planar torsion microsensor for strong magnetic field measurement are as follows:

[0065] (1). On the side of the silicon material layer 2 of the SOI wafer 1 of the sensor body, use deep reactive ion etching technology to pattern-etch a cavity with a depth of 1um, and use lift-off technology to pattern-grow 400nm on the inner surface of the cavity respectively. The second silicon oxide layer 3 and the capacitor upper plate layer 4 . The material of the upper plate layer 4 of the capacitor is aluminum.

[0066] (2). On the single-sided polished wafer 5 of the substrate, a 1.2um deep cavity is etched using deep reactive ion etching technology, so that the single-sided polished wafer 5 has a "concave" shape, and after the cavity is etched A 400nm-thick first silicon oxide layer 6 is grown on the surface of the polished silicon material, and then an aluminum material is grown on the first silicon oxide layer 6 on the inner surface of the cavity as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com