Experimental equipment for drum drying and method for establishing rea model of tobacco drum drying

A technology of drum drying and tobacco, which is used in the preparation of tobacco, tobacco, design optimization/simulation, etc., can solve problems such as inability to know, and achieve accurate and rapid measurement and considerable effect of sample parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

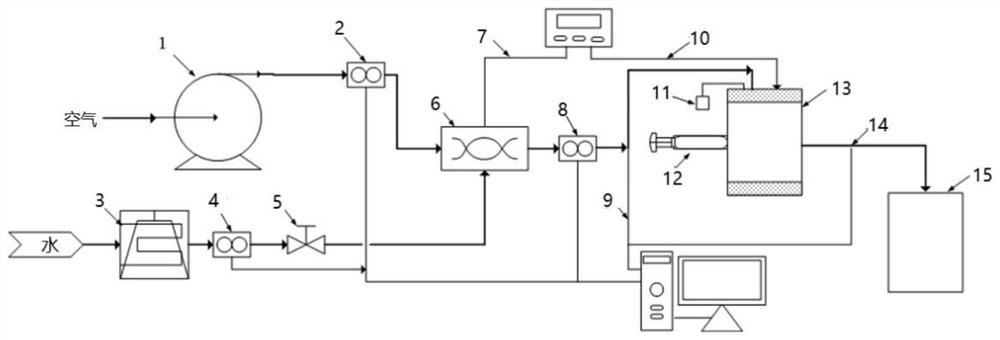

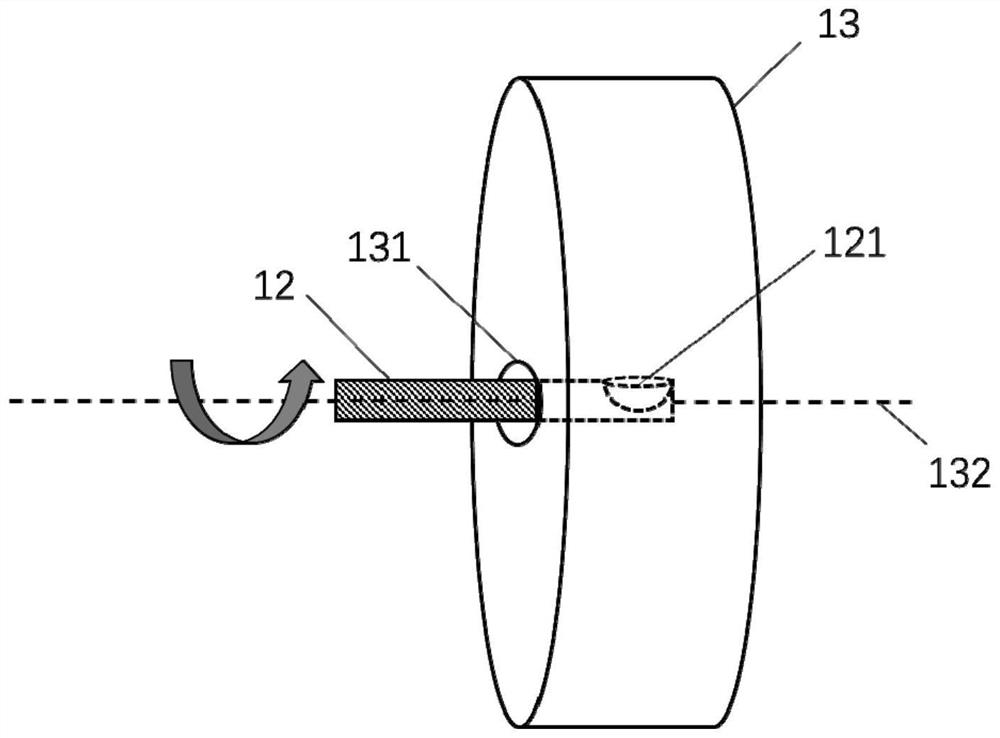

Method used

Image

Examples

Embodiment 1

[0141] 1.1 Sample preparation

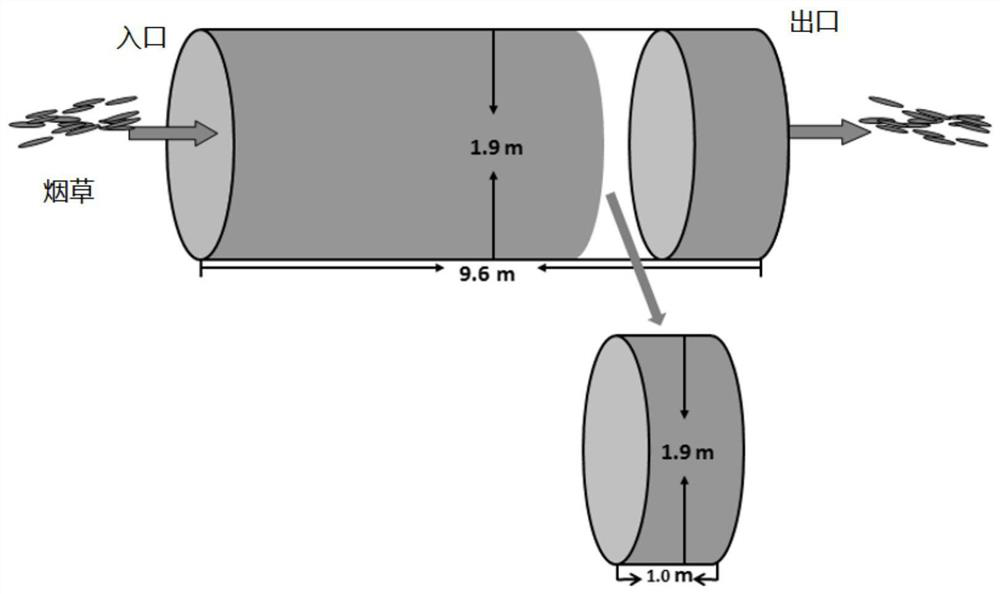

[0142] The upper tobacco and lower tobacco from Sanming, Fujian were selected, and the tobacco leaf material was cut into shreds and then equilibrated in a constant temperature and humidity room for 48 hours, and adjusted to a moisture content of 23% on a wet basis for use. The two tobacco samples had similar three-dimensional dimensions: average length 2 cm, average width 0.1 cm, and average thickness 0.018 cm.

[0143] The surface area A of the tobacco sample can be calculated by the following formula:

[0144]

[0145] In the formula, m (kg) is the initial mass of shredded tobacco, without considering the shrinkage effect of shredded tobacco during the drying process. The initial mass of shredded tobacco in this patent is 2kg, A s (m 2 ) is the surface area of a single tobacco, V s (m 3 ) is the volume of a single cut tobacco, ρ t (kg·m -3 ) is the true density of cut tobacco. According to the three-dimensional size of the tobacc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com