Large-span tension stringing construction method and support frame

A construction method and support frame technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of increased traction tension and construction difficulties, and achieve the effects of shortening traction tension, avoiding bracket phenomenon, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

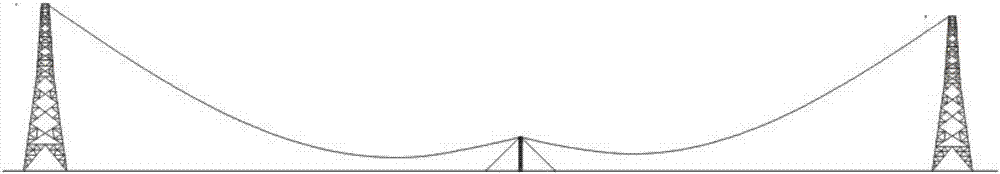

[0016] A large-gage tension setting-out construction method, see attached figure 1 As shown, a large-gage tension pay-off support frame is installed on the ground between two iron towers that need traction and stringing. Little pull.

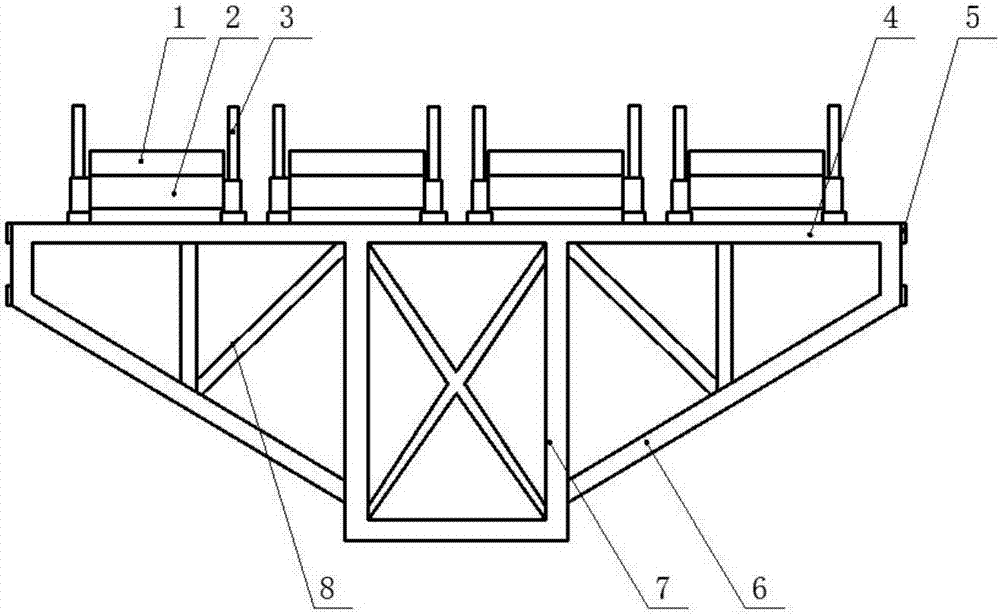

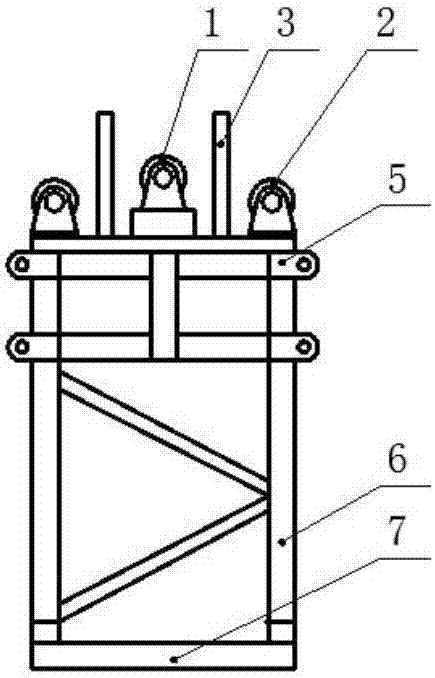

[0017] For the specific structure of the large-gear tension pay-off support frame, refer to the attached figure 2 to attach image 3 As shown, it comprises a pole support 7, an upper support frame 4, an upward pulley block and a limit rod 3, and an upper support frame is fixedly installed symmetrically on both sides of the horizontal side of the upper end of the pole support frame. A set of upward pulley blocks, each set of vertical pulley blocks is fixed at the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com