Double-motor series prediction type direct torque control method

A direct torque control, dual motor technology, used in motor control, motor generator control, electronic commutation motor control, etc., can solve the winding current distortion, deteriorate the steady-state operation performance of the drive system, and store a large storage space for the switching vector table. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

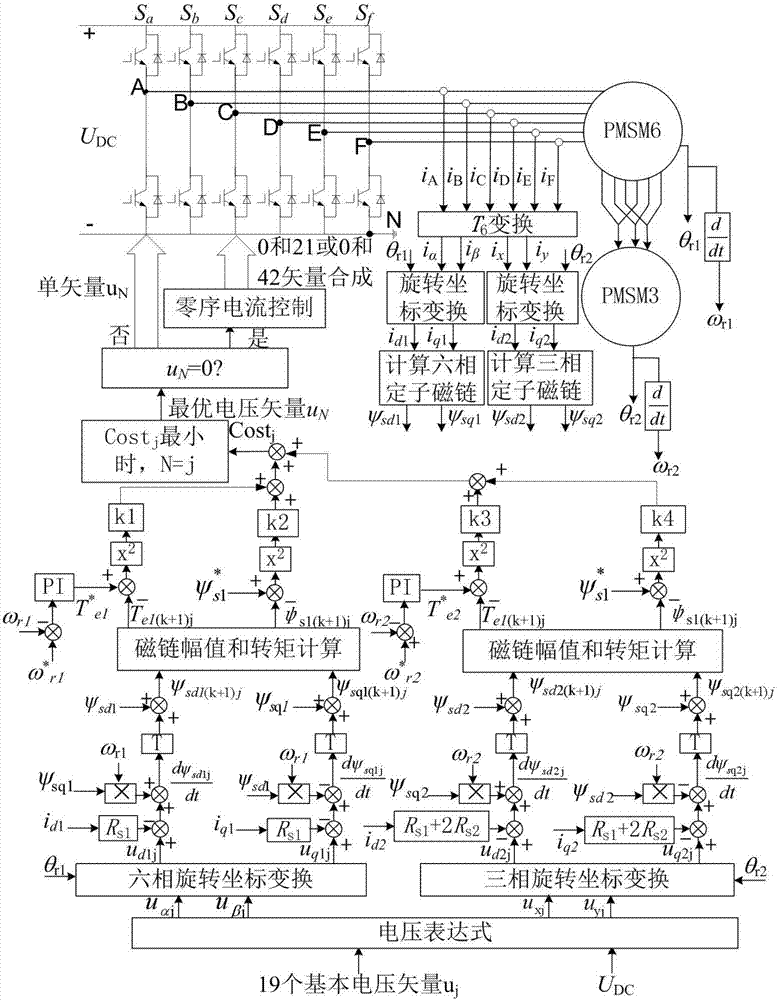

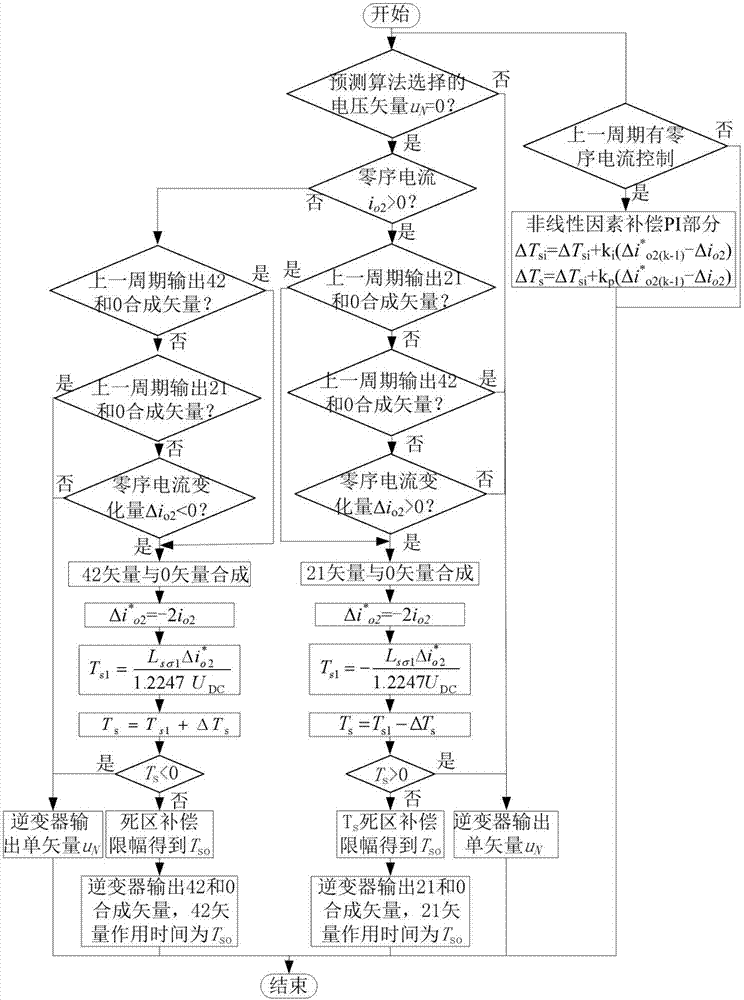

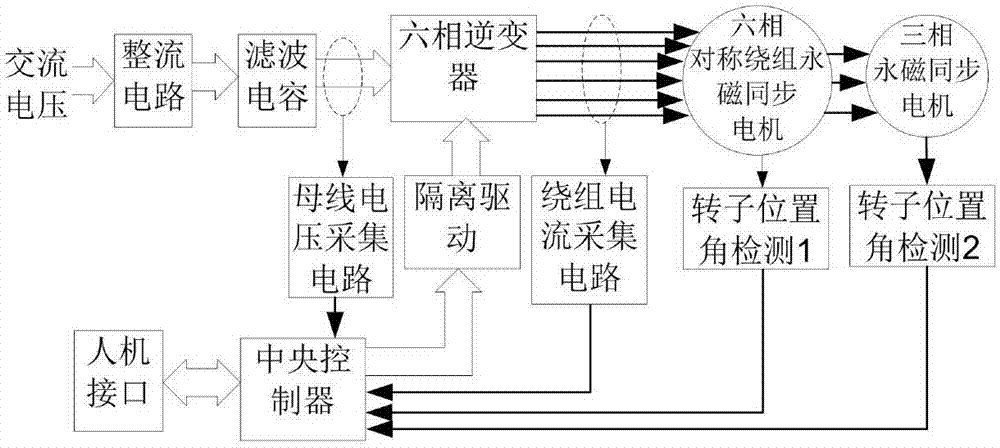

[0072] The present invention proposes a dual-motor series-connected predictive direct torque control method, which has two purposes: one is to reduce the electromagnetic torque ripple of the two motors, and further enhance the stability of the drive system; the other is to realize the active control of zero-sequence current , reduce the distortion of the winding current, thereby improving the steady-state operation performance of the two motors. In order to reduce the system control operation time and improve the rapidity of digital control, the predictive electromagnetic torque and stator flux linkage control method of partial voltage vector with zero sequence plane voltage of 0 is adopted; through the effect of 0 and 21 or 0 and 42 voltage vector Real-time adjustment of time to achieve zero-sequence current control. The specific explanation is as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com