Paper scrap self-cleaning type paper cutting device

A self-cleaning, paper-based technology, applied in metal processing, etc., can solve problems such as different cleaning methods, accidents, and differences in cleaning effects, and achieve the effects of keeping the environment clean, improving work efficiency, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

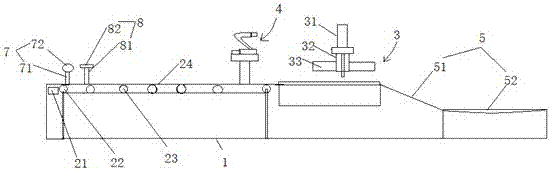

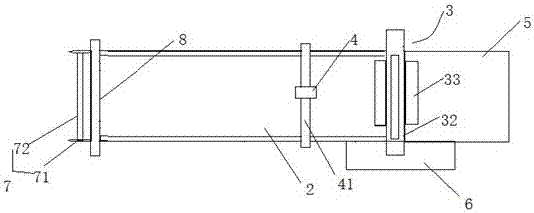

[0019] Such as Figure 1-2 The described self-cleaning paper cutting device for paper scraps comprises a frame 1 on which a conveying device 2, a cutting device 3, a blower device 4, a paper receiving device 5 and a paper scrapping device are arranged. Collecting tank 6, the conveying device 2 is arranged on the left side of the cutting device 3, the blowing device 4 is fixed on the tail end of the conveying device 2 through the support frame 41, and the paper dust collecting tank 6 is fixed on the frame 1 and Located below the cutting device 3 , the paper receiving device 5 includes an inclined conveying plate 51 and a paper collecting tank 52 .

[0020] In this embodiment, the conveying device 2 is provided with a roll paper fixing mechanism 7, and the roll paper fixing structure 7 is provided with a tensioner.

[0021] In this embodiment, the roll paper fixing mechanism 7 includes support seats 71 and detachable support shafts 72 arranged at both ends of the conveying devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com