Automobile body sling

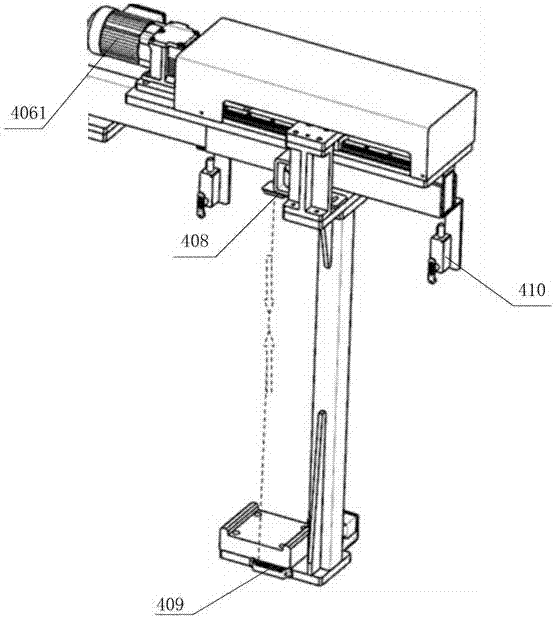

A technology of automobile body and spreader, which is applied in the direction of load hanging components, cranes, traveling bridge cranes, etc., and can solve the problems of reduced body width, insufficient spreader hooks, and lack of flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The core of the present invention is to provide an automobile body hanger to increase the flexibility of the hanger, thereby reducing investment costs and improving efficiency.

[0060] Explanation of related terms

[0061] Spreader: Here it refers to the tooling that suspends the product to keep it off the ground.

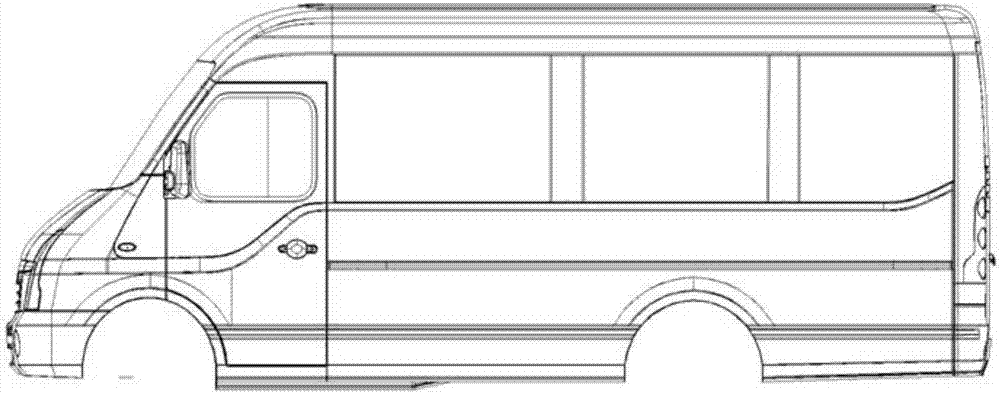

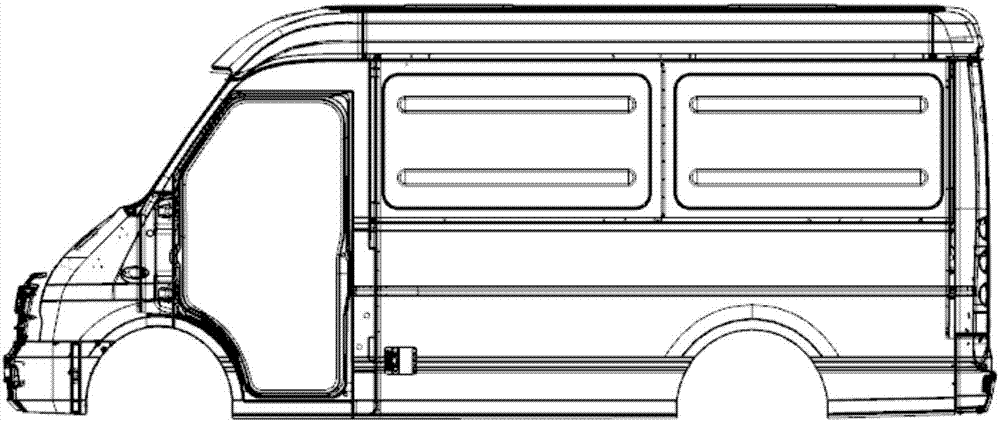

[0062] Flexibility: here refers to a production equipment that can be used in multiple models at the same time. The wider the scope of application, the higher the degree of flexibility.

[0063] Automation: refers to the process in which the equipment achieves the expected goal through automatic detection, information processing, analysis and judgment, manipulation and control according to human requirements without the direct participation of people or fewer people. The fewer people directly involved, the higher the degree of automation.

[0064] Models on the same platform: In order to save costs, automobile companies make some small modifications on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com