Novel magnetic electrolytic composite polishing head

A compound polishing and polishing head technology, which is applied in the field of polishing technology and processing technology, can solve the problems of weak magnetic field strength, small size of polishing head, and the influence of magnetic electrolysis compound polishing, and achieve the effect of convenient magnetic field strength, convenient control and flexible solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing, parts and effects thereof of the present invention are described:

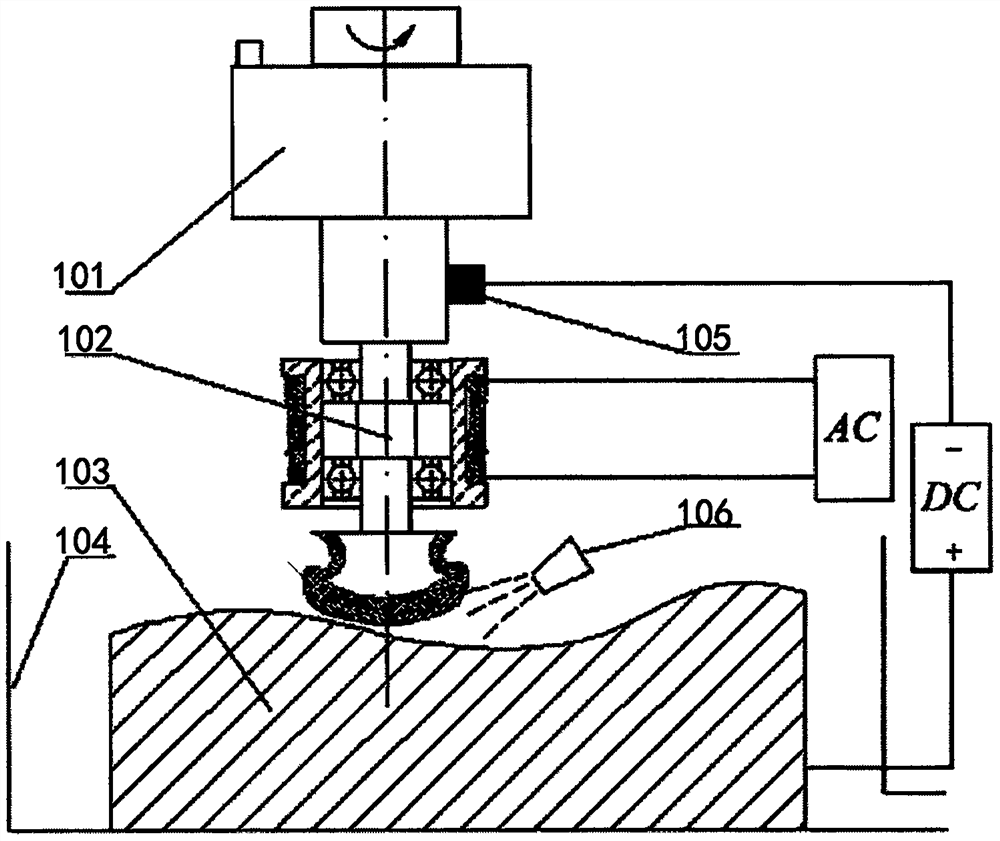

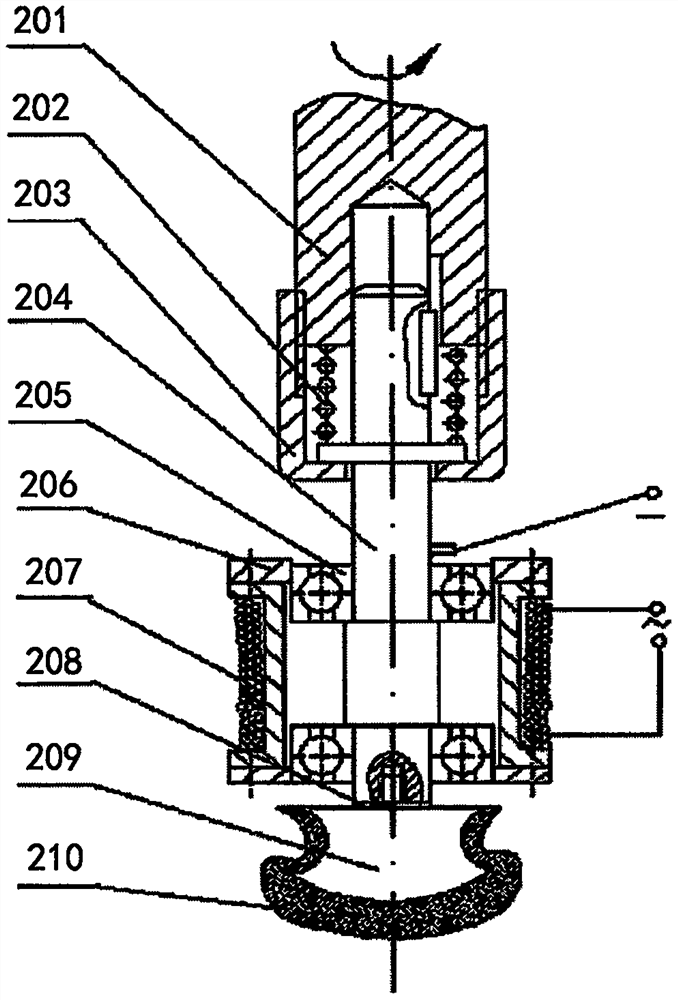

[0011] Such as figure 1 , figure 2 As shown, a novel magnetic electrolytic composite polishing head includes a magnetic electrolytic composite polishing head 102 and a speed increasing device 101 . Wherein the rear handle 201, the shaft 204, the electromagnet 207, and the polishing head 209 are all installed in the magnetic electrolytic composite polishing head 102.

[0012] The above-mentioned rear handle 201 is connected with the shaft 204 by an adjustment sleeve 203, and a spring 202 is installed, the rear handle 201 is pressed above the spring 203, and the adjustment sleeve 203 is wrapped around the rear handle 201, the spring 202, and the shaft 204, thereby playing The function of the flexible connection between the rear handle 201 and the shaft 204.

[0013] The above-mentioned electromagnet 207 is connected with the shaft 204 by means of the bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com