Automatic descaling delaying valve

A technology of automatic descaling and time-delay valves, which is applied in the direction of valve devices, functional valve types, engine components, etc., can solve the problems of increasing user cost and maintenance cost, increasing manufacturing difficulty and cost, and limiting the service life of diaphragms, etc. problem, to achieve the effect of stable and reliable self-control delay, cost reduction, and labor-saving operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

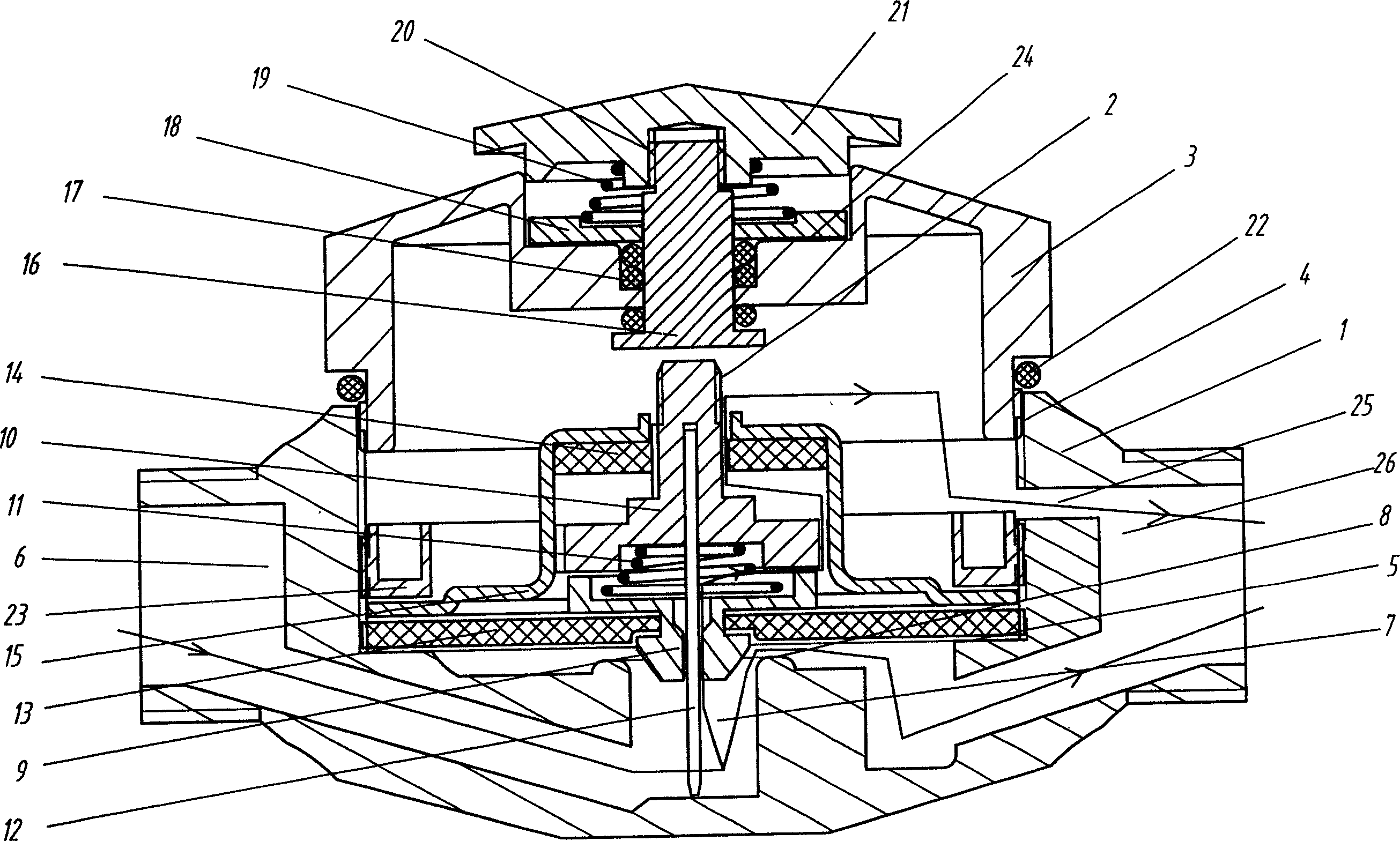

[0012] It can be seen from the drawings that the automatic descaling delay valve includes a valve body 1, a valve core assembly 2 fixed in the valve body and a valve cover 3 connected to the valve body 1, wherein the valve body is provided with an open inner cavity, and the inner cavity The wall is provided with threads 4 for connecting the "convex" shaped gland 15, the fastening ring 23 and the valve cover 3. A sealing platform 5 is provided at the bottom of the inner chamber, and a water inlet hole 7 in the center of the inner chamber communicated with the water inlet connection interface 6 is arranged in the center. The water inlet hole 7 is provided with a sealing boss 8 along the edge, so as to make the structure of the valve body 1 more compact and the shape more compact. Aesthetically pleasing, the shape of the valve body 1 is in the shape of a "turtle body" or "round cake", and the inlet and outlet water connection interfaces 6, 26 are arranged on the center line of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com