Copper Plating Solution And Copper Plating Method

A copper plating solution and copper plating technology, applied in the direction of liquid chemical plating, coating, metal material coating process, etc., can solve the problems of poor adhesion of the plating layer, and achieve the effect of uniform adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

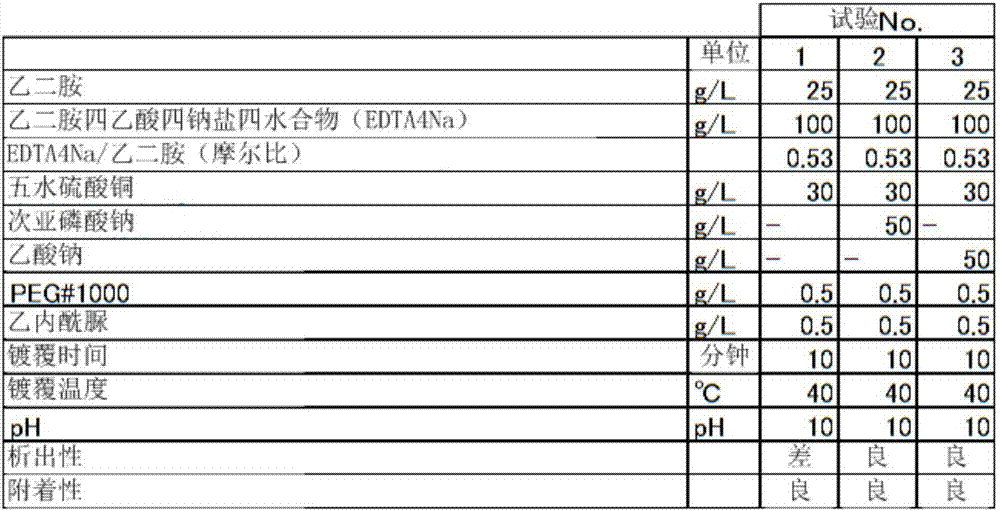

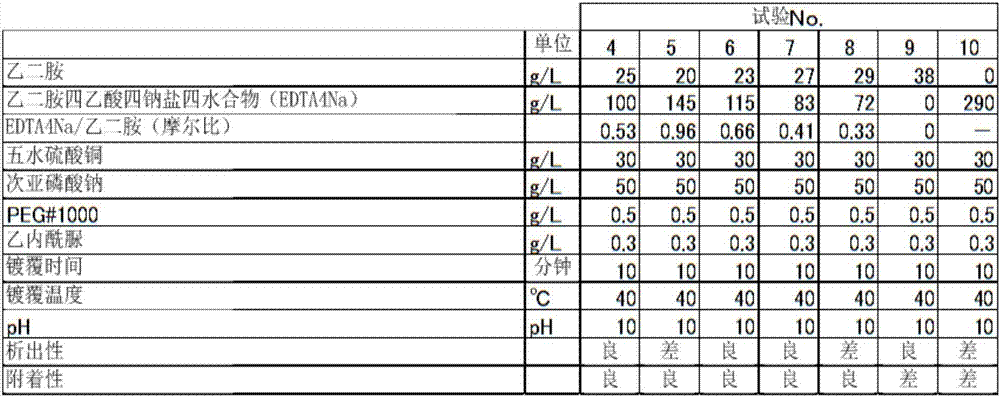

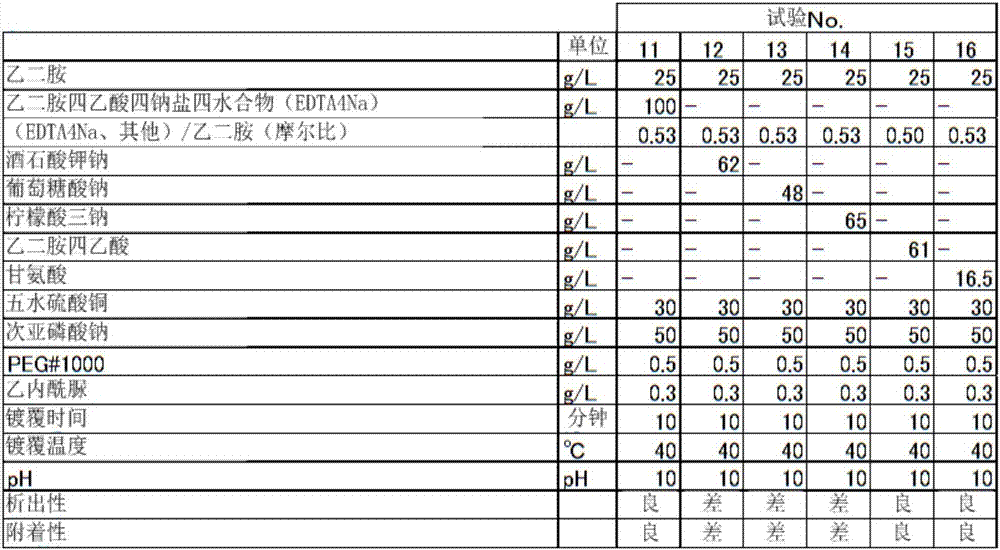

[0025] The copper plating solution involved in the first embodiment includes: water-soluble copper salt; ethylenediamine; at least one of EDTA, EDTA substituted derivatives, ethylenediamine derivatives and glycine; hydantoin and its substituted derivatives at least one of the The copper plating solution is used for replacing copper plating on an aluminum base material or an aluminum alloy base material. In this case, copper displacement plating is performed on a non-galvanized substrate that has not been galvanized. Since the ionization tendencies are different, the aluminum placed in the copper plating solution of this embodiment becomes aluminum ions and dissolves in the copper plating solution, and the copper ions are deposited on the surface of the aluminum substrate or the aluminum alloy substrate. Copper ions and aluminum ions in the plating solution use at least one of EDTA, EDTA substituted derivatives, ethylenediamine derivatives and glycine and ethylenediamine as co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com