Crispy fish-flavored bean curd production line

A puff pastry fish and production line technology, which is applied in the puff pastry fish tofu production line, can solve problems such as greasy, achieve the effects of refreshing taste, promoting ripening and shaping, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

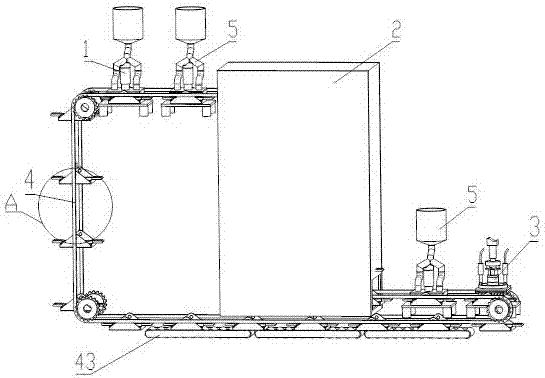

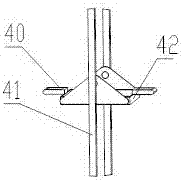

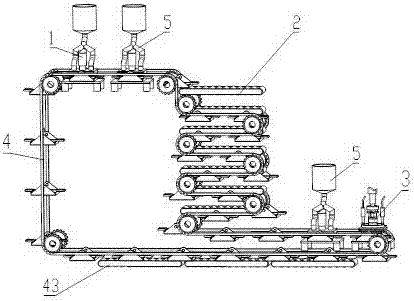

[0043] see Figure 1 to Figure 8 , the present invention provides a production line for puff pastry fish tofu, comprising a minced meat production unit, a filling unit 1, a shaping unit 2, a cutting unit 3, and a packaging unit arranged in sequence, and also includes a sprocket chain combination 4 as a transmission mechanism; the filling unit uses The mold is a square shallow plate, and the shaping unit adopts the method of electric oven heating to shape the fish tofu, and the combination of sprockets and chains passes through the box of the shaping unit 2;

[0044] Between the filling unit 1 and the shaping unit 2, there is a covering unit 5 for adding a second material on the upper surface of the material as a covering surface.

[0045] The minced meat production unit adopts conventional technology, and usually includes a chopping device, which is used to prepare materials and seasonings into minced meat, which will be loaded into a mold in the next step.

[0046] The filli...

Embodiment 2

[0070] see Figure 5 and Figure 6 , On the basis of Example 1, different from Example 1 is that a single cutting device is used to cut the shaped fish tofu.

[0071] Cutting unit 3 comprises the cutter group 301 that is positioned at the bottom, and described cutter group 301 is made up of several blades that are arranged in parallel; The upper side of cutter group 301 is horizontally provided with heating box 302, and electric heating tube is arranged in the heating box 302; 301, the heating box 302 is made of stainless steel, and the upper part of the heating box 302 is provided with a push rod mechanism that allows the cutter group 301 to press down.

[0072] The push rod mechanism includes a main push rod 303 arranged on the central upper part of the heating box 302, and auxiliary push rods 304 on both sides of the main push rod 303; the bottom end of the main push rod 303 and the upper surface of the heating box 302 A steering mechanism 305 is arranged between them, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com