Apparatus used for pasting edge strips of cabin air filter

An air-conditioning filter and sticking device technology, which is applied in the fields of dispersed particle filtration, chemical instruments and methods, gas treatment, etc., can solve the problems of uneven sticking, low processing efficiency, affecting product quality, etc., and achieves high cutting efficiency. Improve work efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

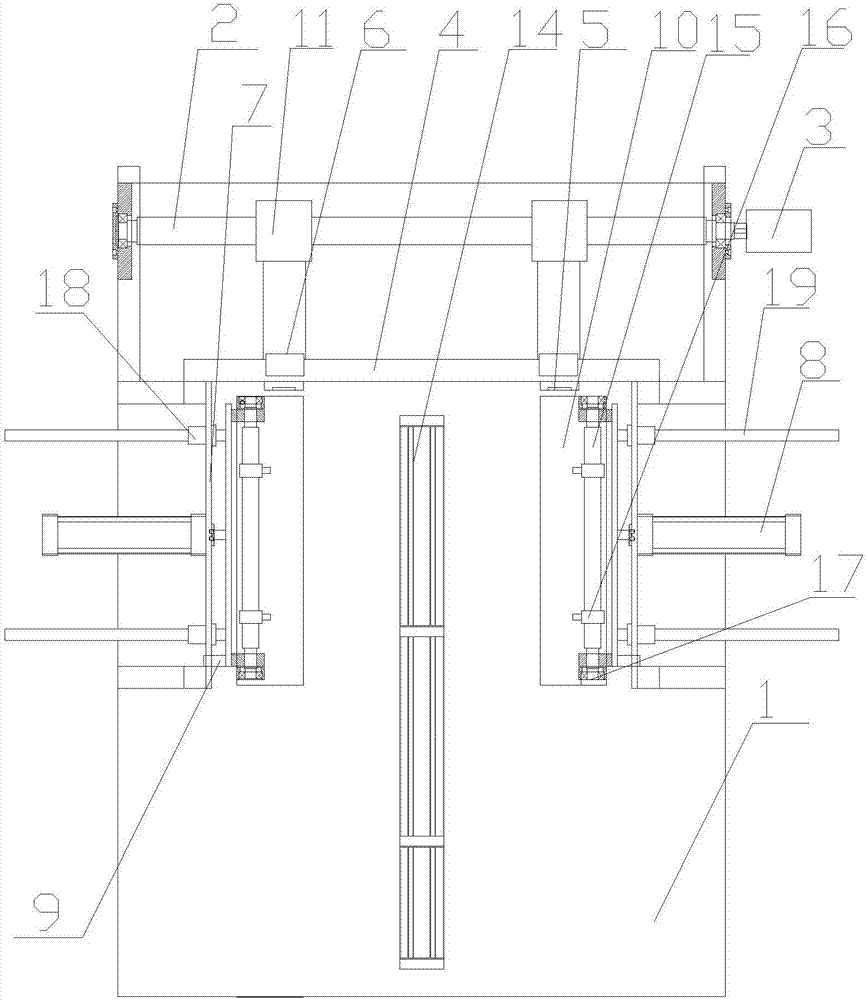

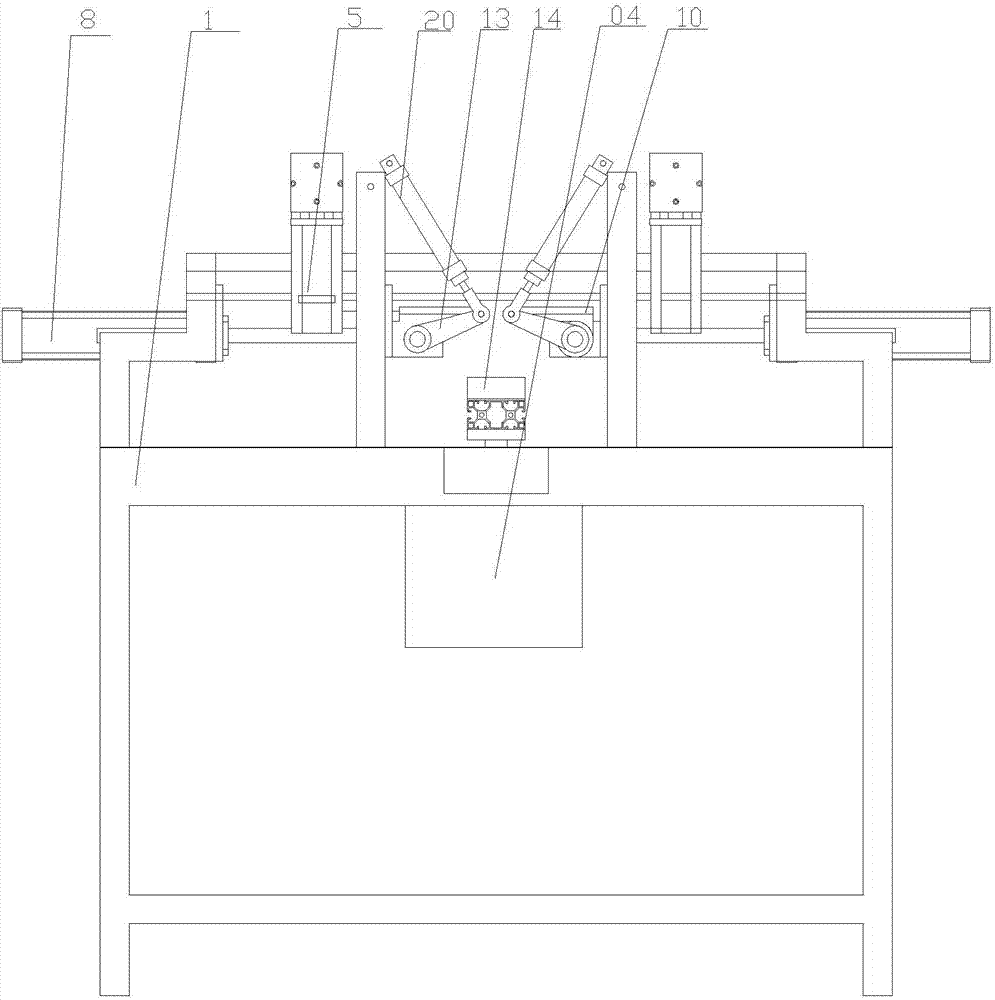

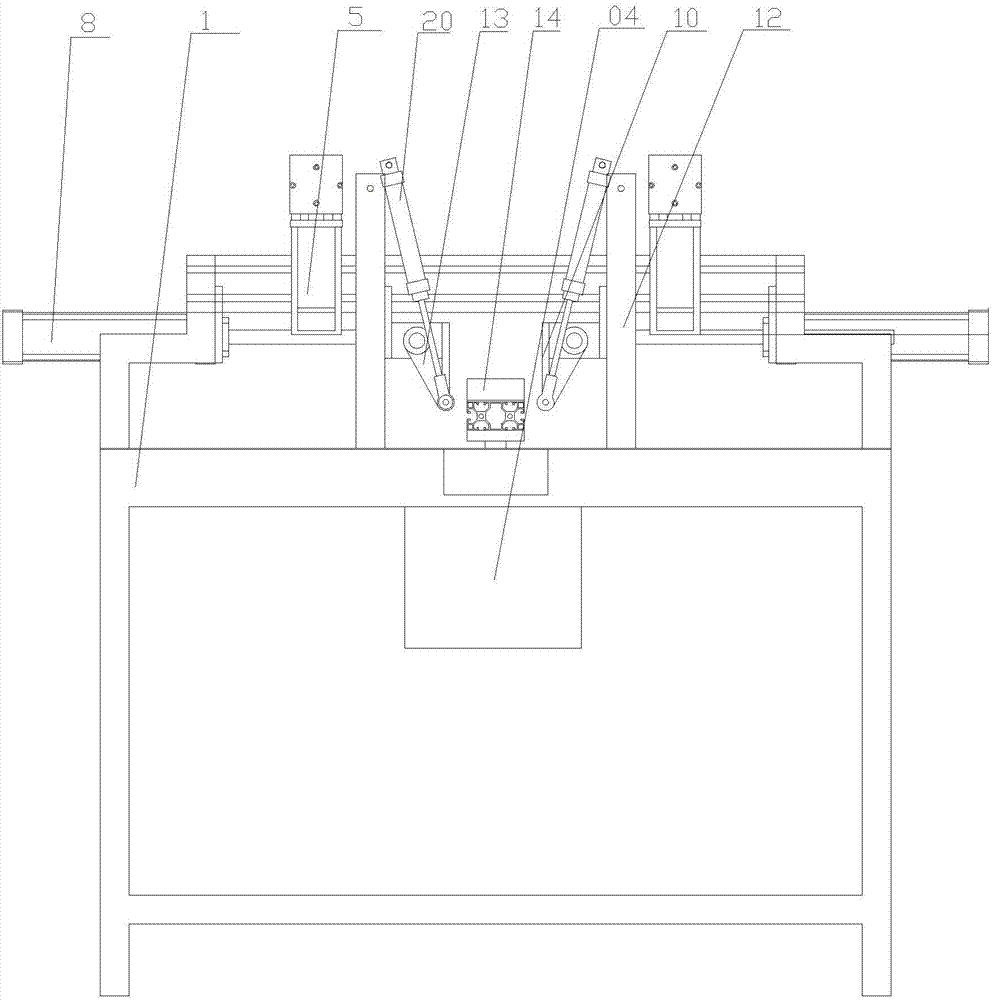

[0020] like Figure 1-Figure 5 As shown in the figure, a side strip sticking device for an air conditioner filter, the main body is a working platform 1, the rear end of the working platform 1 is provided with a conveying shaft 2, and two sets of edge paper card sleeves 11 are arranged on the conveying shaft 2. A drive motor 3 is installed at one end of the rotating shaft 2, a vertical plate 4 is installed at the front end of the conveying shaft 2, and a paper cutter 5 is installed at the position of the vertical plate 4 at the front end of the card sleeve 11. Glue applicator 6, two sets of positioning plates 7 are installed at the front end of the vertical plate 4, a lifting cylinder 8 fixed on the working platform 1 is installed on the rear side of the positioning plate 7, and two sets of lug plates 9 are installed on the positioning plate 7. The positioning plate A flipping plate 10 with corresponding lugs 9 is installed on the 7, and the lugs 9 are movably connected. A col...

Embodiment 2

[0022] like Figure 1-Figure 5 As shown in the figure, a side strip sticking device for an air conditioner filter, the main body is a working platform 1, the rear end of the working platform 1 is provided with a conveying shaft 2, and two sets of edge paper card sleeves 11 are arranged on the conveying shaft 2. A drive motor 3 is installed at one end of the rotating shaft 2, a vertical plate 4 is installed at the front end of the conveying shaft 2, and a paper cutter 5 is installed at the position of the vertical plate 4 at the front end of the card sleeve 11. Glue applicator 6, two sets of positioning plates 7 are installed at the front end of the vertical plate 4, a lifting cylinder 8 fixed on the working platform 1 is installed on the rear side of the positioning plate 7, and two sets of lug plates 9 are installed on the positioning plate 7. The positioning plate A flip plate 10 with corresponding lugs 9 is installed on the 7, and a rotating shaft 11 is used to connect the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com