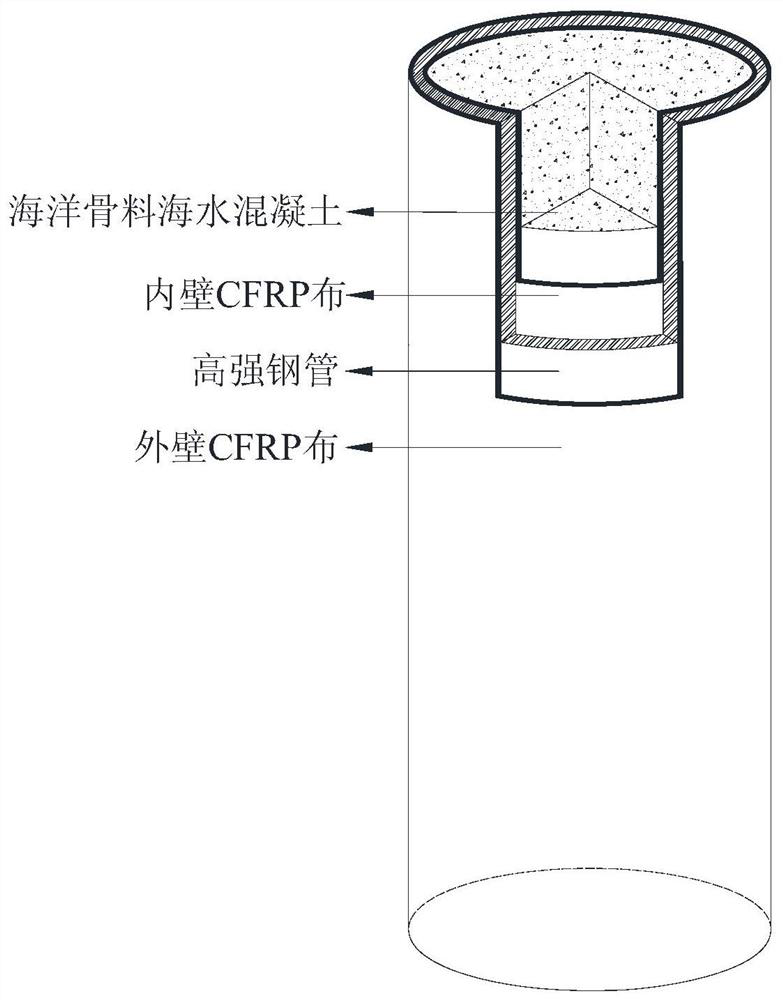

Corrosion-resistant CFRP-high-strength steel composite pipe marine aggregate seawater concrete composite column

A composite pipe and concrete technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of composite columns not having corrosion resistance, poor brittle failure, complex implementation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A corrosion-resistant CFRP-high-strength steel composite pipe marine aggregate seawater concrete composite column is manufactured by the method of the invention. The height of the high-strength steel pipe is 600mm, the diameter is 152mm, the wall thickness is 5mm, and the strength is Q345; the length of the cut CFRP cloth is 500mm, and the width is 600mm. The core concrete is marine aggregate seawater concrete, and the strength grade is C40. Specifically include the following steps:

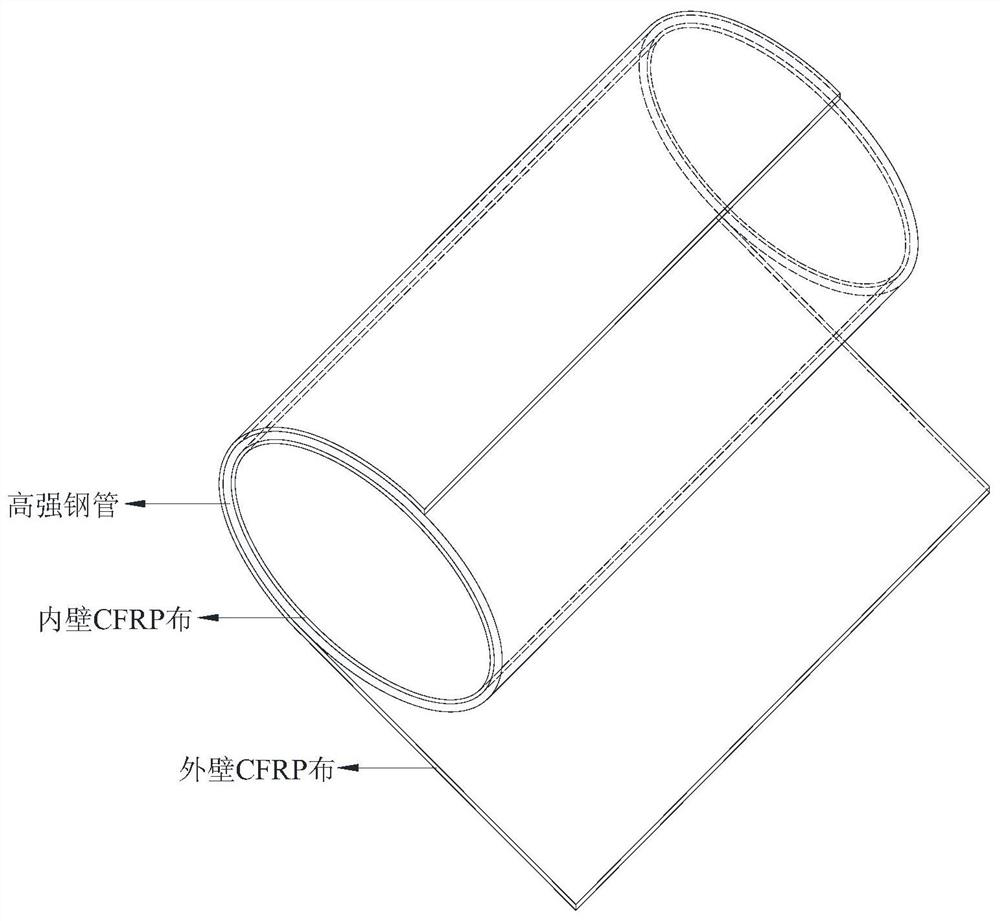

[0036] (1) Fabrication of corrosion-resistant CFRP-high-strength steel composite pipe

[0037] The first step is to clean the dust and impurities on the inner and outer surfaces of the high-strength steel pipe, and keep the inner and outer surfaces of the high-strength steel pipe dry;

[0038]The second step is to cut and collage a required inner wall CFRP cloth according to the design requirements, and evenly coat the structural adhesive on the inner wall of the high-strength steel pipe ...

Embodiment 2

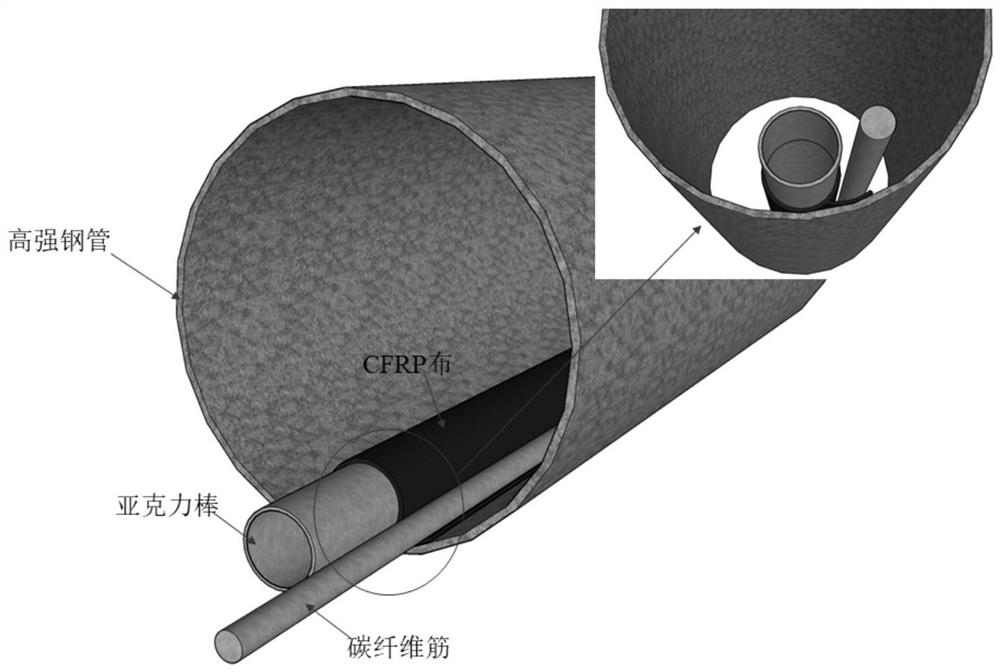

[0053] A corrosion-resistant CFRP-high-strength steel composite pipe marine aggregate seawater concrete composite column, which is composed of marine aggregate seawater concrete, high-strength steel pipes and CFRP cloth; the CFRP cloth is pasted on the inner and outer walls of high-strength steel pipes to form a CFRP-high-strength steel composite pipe, The marine aggregate concrete is filled in the CFRP-high-strength steel composite pipe. The manufacturing method of the corrosion-resistant CFRP-high-strength steel composite pipe marine aggregate seawater concrete composite column includes the following three main steps: the inner wall of the high-strength steel pipe is pasted with CFRP cloth, the outer wall of the high-strength steel pipe is pasted with CFRP cloth and filled with marine aggregate concrete; the specific steps are as follows :

[0054] Step 1) Calculate the inner wall area according to the inner diameter of the high-strength steel pipe, and then design the horiz...

Embodiment 3

[0069] The manufacturing method of the corrosion-resistant CFRP-high-strength steel composite pipe marine aggregate seawater concrete composite column of this embodiment is the same as that of Example 1, wherein the marine aggregate seawater concrete is composed of the following raw materials in parts by weight: 400 parts of ordinary portland cement , 600 parts of coral coarse aggregate, 700 parts of sea sand, 200 parts of seawater, 30 parts of silica fume, 40 parts of fly ash, and 0.8 part of a water reducing agent, which is a polycarboxylic acid high-performance water reducing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com