Washing and soaking device for combustion jet of gas furnace

A technology for burning nozzles and gas furnaces, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of troublesome arrangement, low soaking efficiency, high cost, etc., so as to improve soaking efficiency, easy to Promotion, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

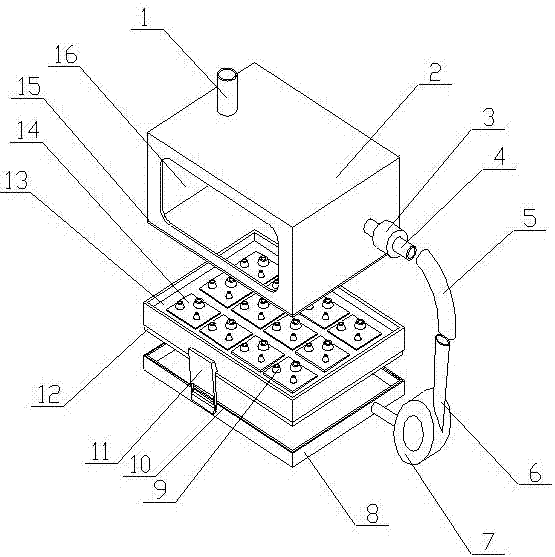

[0013] A gas furnace combustion nozzle cleaning and soaking device of the present invention is realized in this way. When in use, there are four passages in the combustion nozzle, including a spare passage. It is necessary to clean the three passages used. When the nozzle is soaked, First, place the removed nozzles on multiple magnetic plates (14) one by one, and the magnetic plates (14) will absorb the nozzles, and make the three channels to be cleaned on the nozzles and the three channels on the magnetic plates (14) The hollow connectors (9) are connected in one-to-one correspondence, cover the box cover, and fix it with the locking buckle (11), inject the soaking liquid into the middle tray (13) through the liquid injection pipe (1), and the soaking liquid flows into the middle tray (13), and then soak the nozzle on the magnetic plate (14), the soaking liquid flows into the three channels in the nozzle, and soaks the blockages such as carbon deposits in the three channels, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com