Rail-based porphyra cultivation rope efficient soaking and float clamping integrated machine

An all-in-one, floating technology, applied in horticulture, botany equipment and methods, plant cultivation, etc., can solve the problems of difficult soaking, low soaking efficiency, and low uniformity of spore coverage, so as to achieve uniform coverage and improve soaking efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

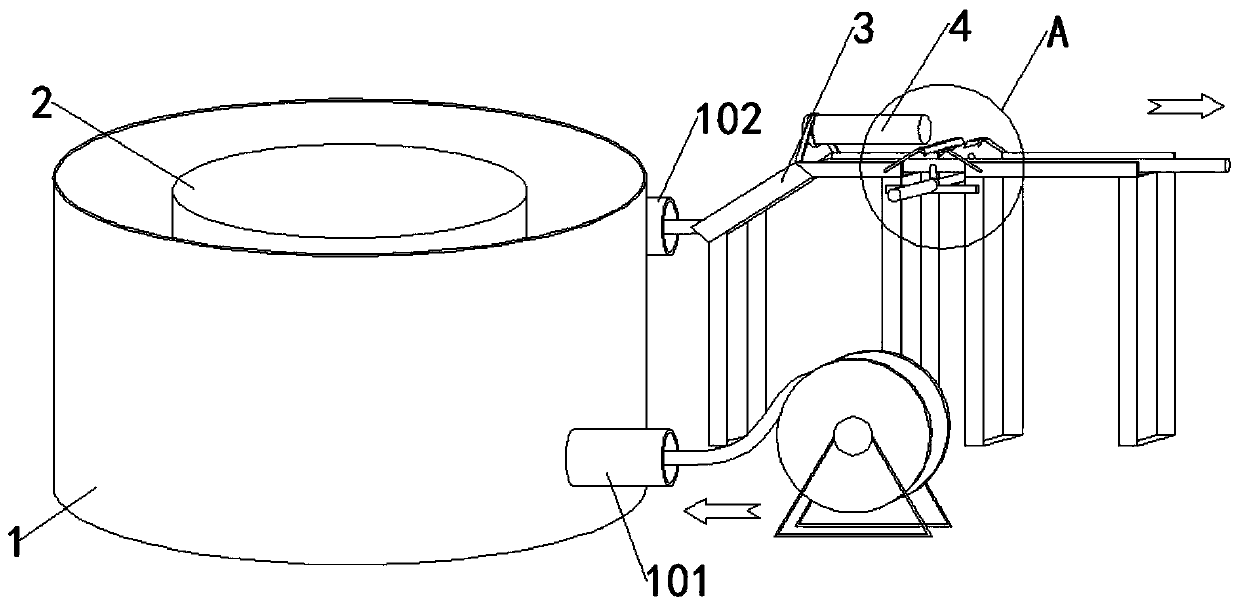

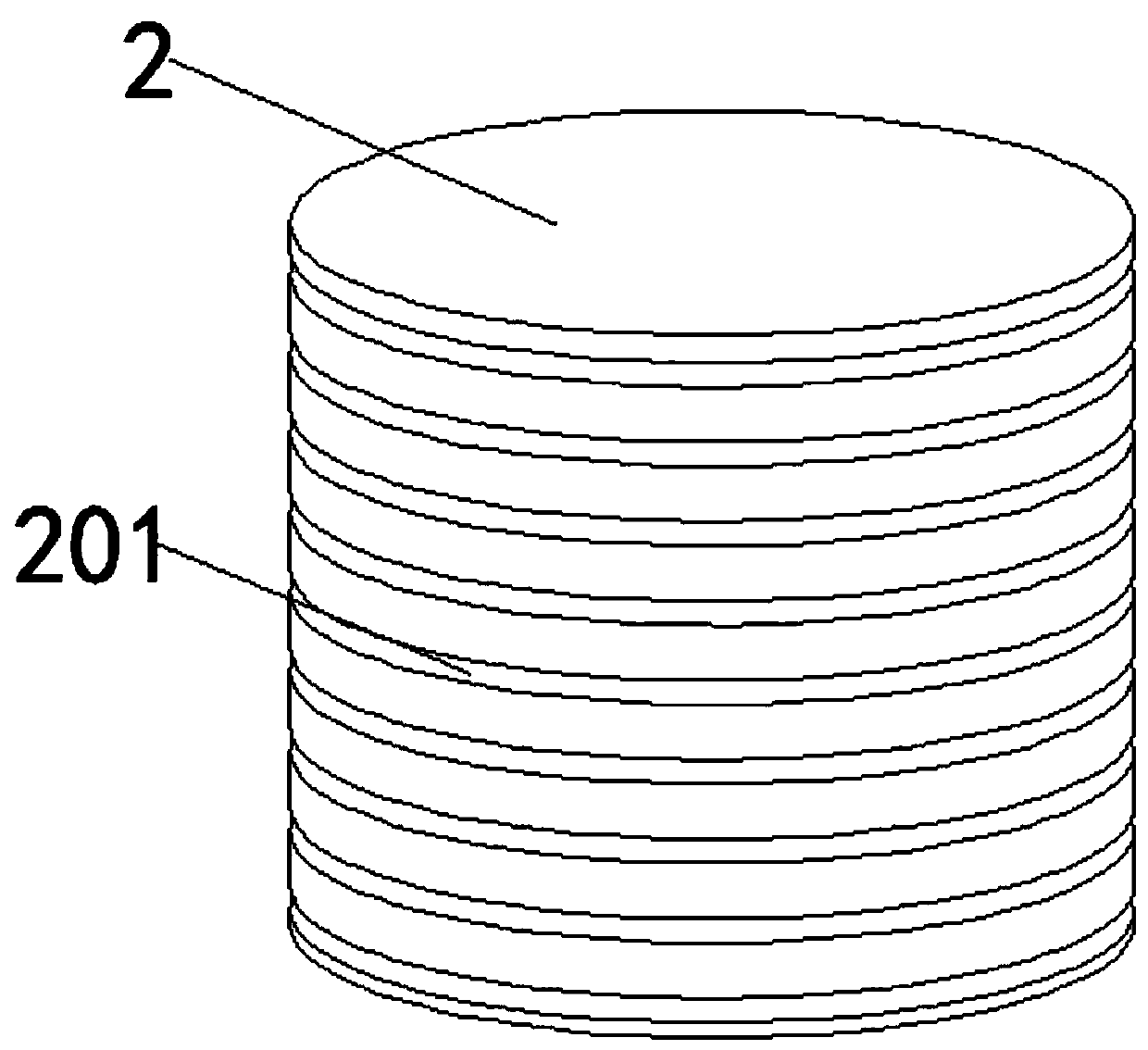

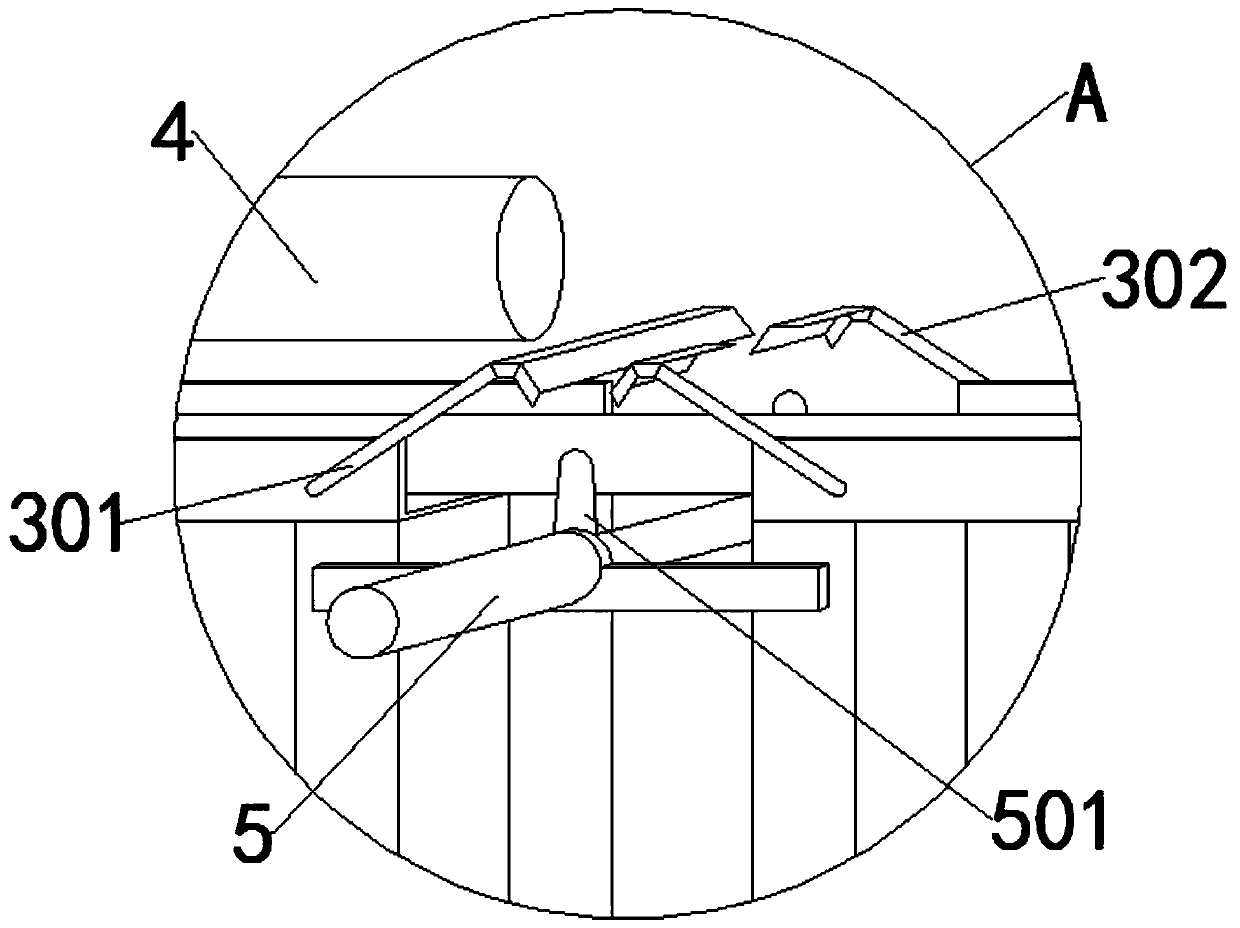

[0027] see Figures 1 to 6, in an embodiment of the present invention, a base rail type seaweed cultivation rope efficient soaking and floating clamping integrated machine, including a fungal spore bucket 1, a sealed inlet 101, a sealed outlet 102, a drum 2, a threaded groove 201, a guide rail 3, Limiting plate 1 301, limiting plate 2 302, floating pusher 4, top column 401, spring 4011, roller 4012, ring fixing plate 4013, gear 402, triangular limiting plate 403, screw rod 404, hydraulic rod 5, The splint 501, the float 6, the jack plate 601 and the spline 602, the right side surface of the spore bucket 1 is provided with a sealed inlet 101, and the right side surface of the spore bucket 1 is provided with a sealed outlet 102, and the sealed inlet 101 is located at the sealed outlet 102 At the front end, the inner middle of the spore barrel 1 is rotatably connected with a drum 2, and the outer surface of the drum 2 is nested with a threaded groove 201, and the right side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com