Flexible pneumatic mechanical arm achieving multifunctional gripping

A pneumatic manipulator and multi-functional technology, applied in the field of manipulators, can solve the problems of poor stability and inaccurate grasping, and achieve the effects of good stability, accurate grasping and large deformation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

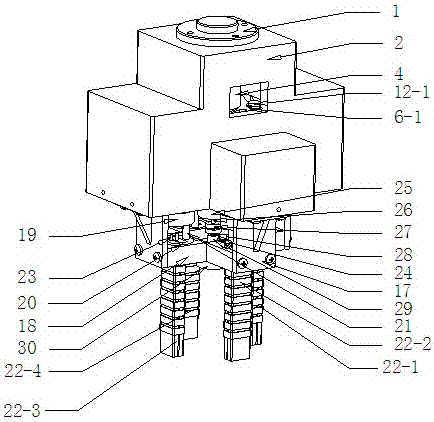

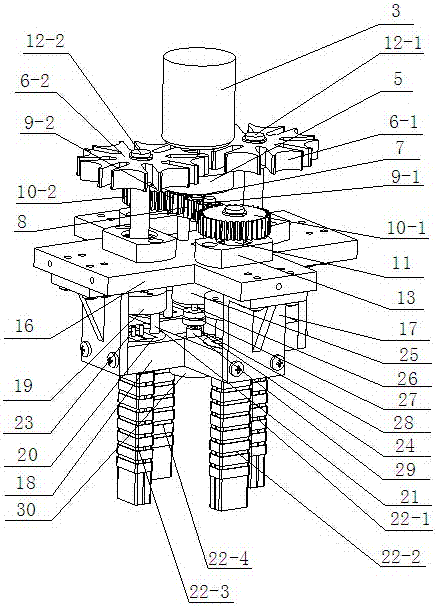

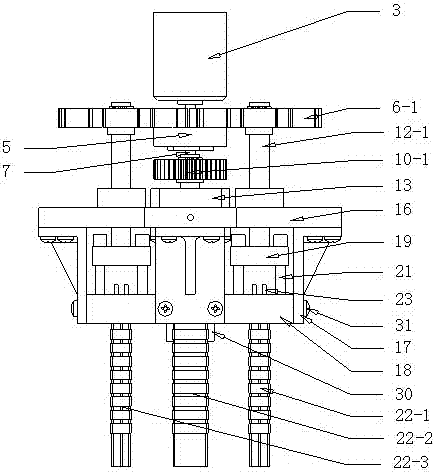

[0035] refer to Figure 1-13 , this embodiment includes a driving mechanism and a gripper, the driving mechanism is connected to the gripper, and the gripper includes a first flexible finger 22-1, a second flexible finger 22-2, a third flexible finger 22-3, a fourth flexible finger Flexible fingers 22-4, when grabbing an object, the first flexible finger 22-1, the second flexible finger 22-2, the third flexible finger 22-3, and the fourth flexible finger 22-4 grasp in a "cross" state Or grabbing in a "rectangular" state, being in a "cross-shaped" state means that each flexible finger is respectively located at the end of the "cross", the first flexible finger 22-1, the second flexible finger 22-2, the third flexible finger 22-3, the fourth flexible fingers 22-4 are arranged in a clockwise direction; being in a "rectangle" state means that each flexible finger is respectively located on the four corners of the "rectangle", the first flexible finger 22-1, the second The flexibl...

Embodiment 2

[0056] The difference between this embodiment and Embodiment 1 is that the first transmission mechanism is a gear mechanism, and the gear mechanism includes a sixth gear, a seventh gear, and an eighth gear; the seventh gear is arranged on one side of the sixth gear, and the eighth gear Set on the other side of the sixth gear, the seventh gear and the eighth gear mesh with the sixth gear respectively, the number of teeth of the seventh gear and the eighth gear is the same, the gear ratio of the sixth gear and the seventh gear is 1:3, the drive The motor 3 drives the sixth gear to rotate 135 degrees clockwise, and the sixth gear and the seventh gear rotate 45 degrees counterclockwise. The sixth gear is arranged above the first gear 8, the first gear 8 and the sixth gear are connected through the sixth gear connecting shaft; the sixth gear is connected with the output shaft of the driving motor 3, and the first transmission shaft is arranged on the seventh gear , the third transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com