Flattening and laminating device for integrated wall panel

A film covering device and integrated wall technology, which is applied in lamination devices, lamination, household walls, etc., can solve problems such as difficulty in achieving smooth film covering, low efficiency, and difficult quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

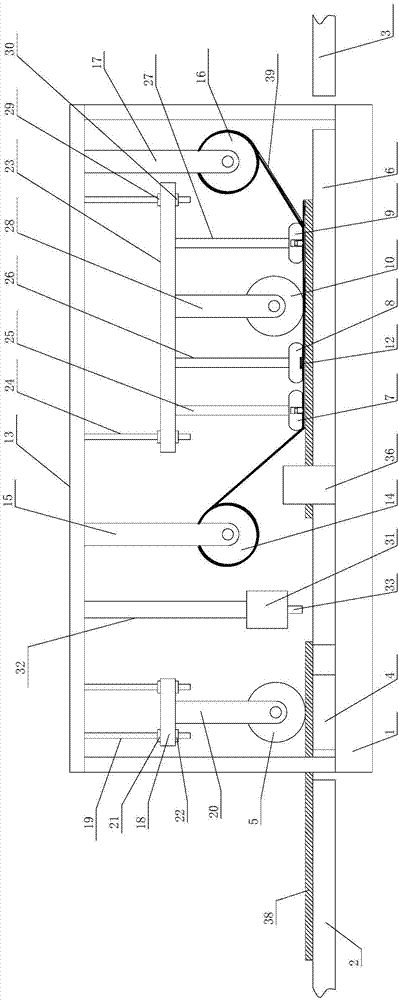

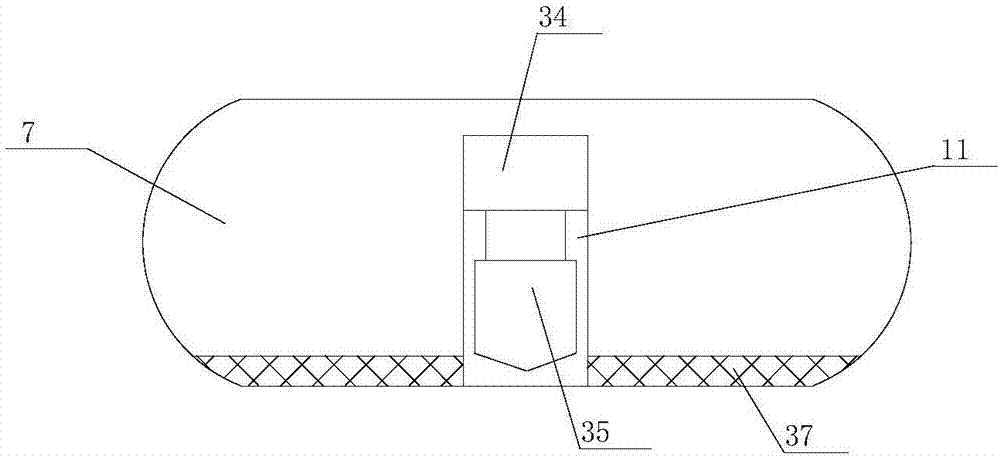

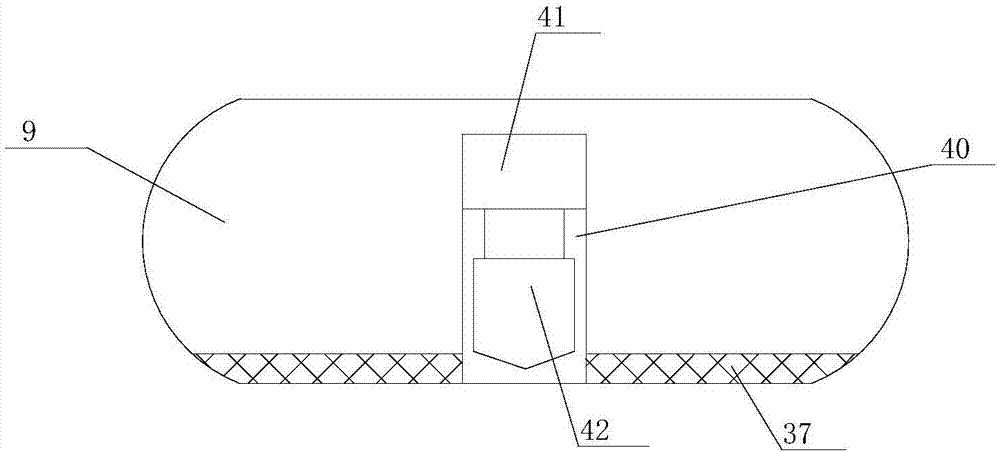

[0025] refer to figure 1 , figure 2 , image 3 , the present invention proposes an integrated wall panel flattening and coating device, including a workbench 1, a first transmission mechanism 2, a second transmission mechanism 3, a mounting frame 13, a flattening mechanism, a coating mechanism, a feeding mechanism, and a receiving mechanism , Dust suction mechanism, wherein:

[0026] The installation frame 13 is located above the workbench 1 and parallel to the workbench 1 .

[0027] The flattening mechanism is arranged on the feeding end of the workbench 1, and the flattening mechanism comprises a support platform 4, a flattening roller 5 and a first drive mechanism, and the support platform 4 is installed on the workbench 1 and the extension direction of the support platform 4 is the same as that of the workbench. 1 in the same width direction, the flattening roller 5 is located above the support table 4 and the distance between the flattening roller 5 and the support ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com