Double-oil-tank communicating structure for automobiles

A dual fuel tank, automobile technology, applied in vehicle components, layout combined with internal combustion engine fuel supply, power plant and other directions, can solve the problems of splash collision, blockage, small ground clearance, etc., and achieves simple structure principle, convenient use, Not easy to be blocked

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] Example: see figure 1 -2.

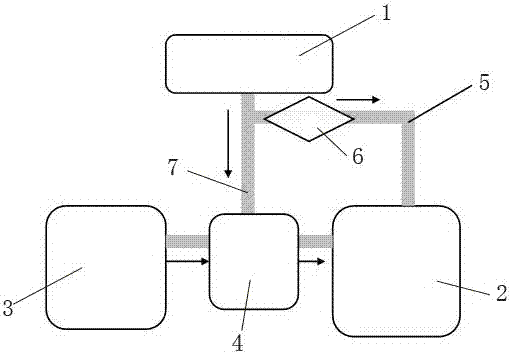

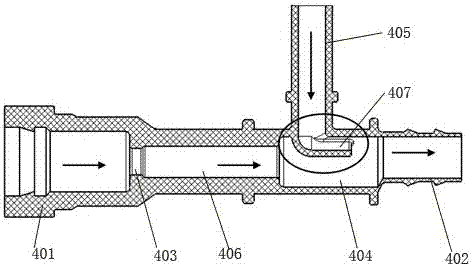

[0024] The invention discloses a communication structure of two fuel tanks of an automobile, which comprises an engine 1, a main fuel tank 2 and an auxiliary fuel tank 3. 1. The main fuel tank 2 and the auxiliary fuel tank 3 are connected through the three-way valve 4. The outside of the three-way valve 4 is in an inverted T shape. The upper vertical section 405 of the three-way valve 4 is connected with the main oil return pipeline 1 of the low-pressure oil circuit of the engine chassis. One end of the branch pipes on both sides of the bottom of the three-way valve 4 is a large end 401, and the other end is a small end 402. The large end 401 communicates with the auxiliary fuel tank 3, and the small end 402 communicates with the main fuel tank 2. The cross section of the large end 401 The area is greater than the cross-sectional area of the small end 402. A throat 403 and a diffuser section are also arranged between the large end 401 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com