A kind of impurity cleaning equipment before grain enters the warehouse

A technology for cleaning equipment and impurities. It is applied in the direction of solid separation, filter screen, grille, etc. It can solve the problems that affect the health of operators and management personnel, the cleaning effect is difficult to meet the national standard requirements, and the dust on the cleaning site is flying, so as to achieve the effect of cleaning and removing impurities. Good, avoid equipment damage, compact structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing:

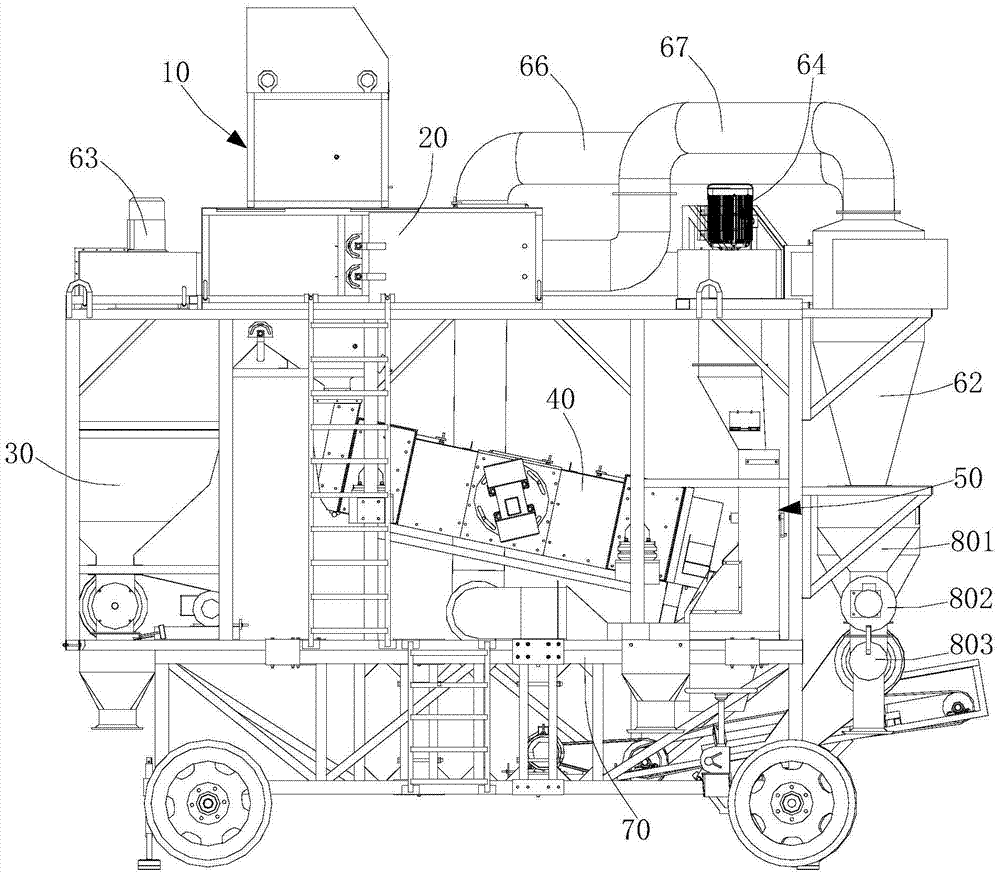

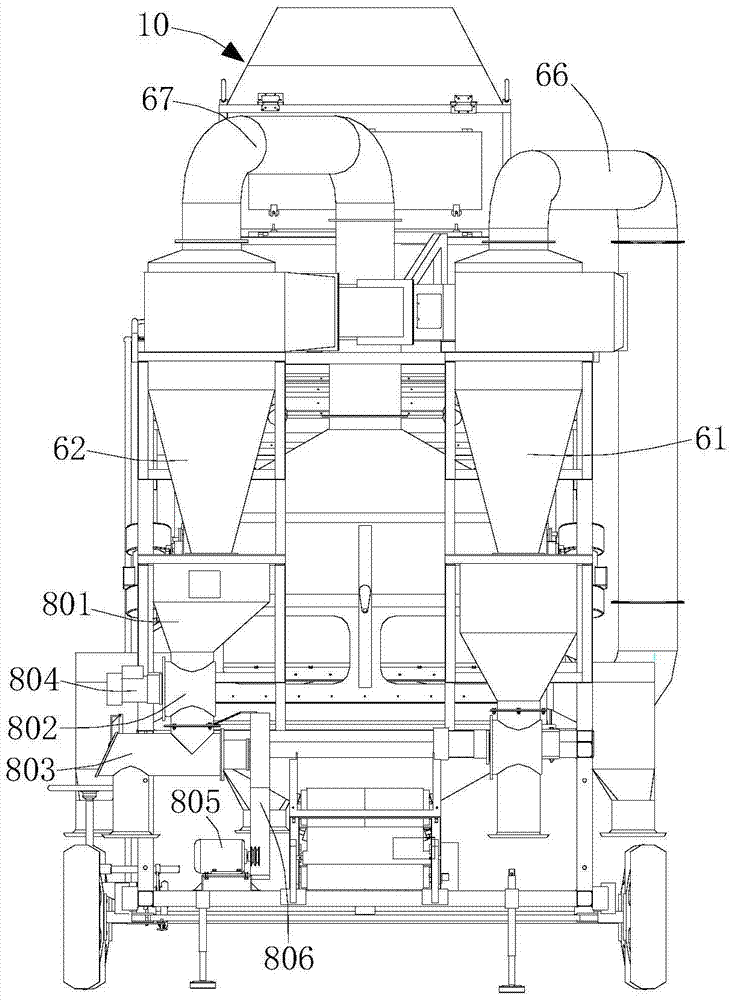

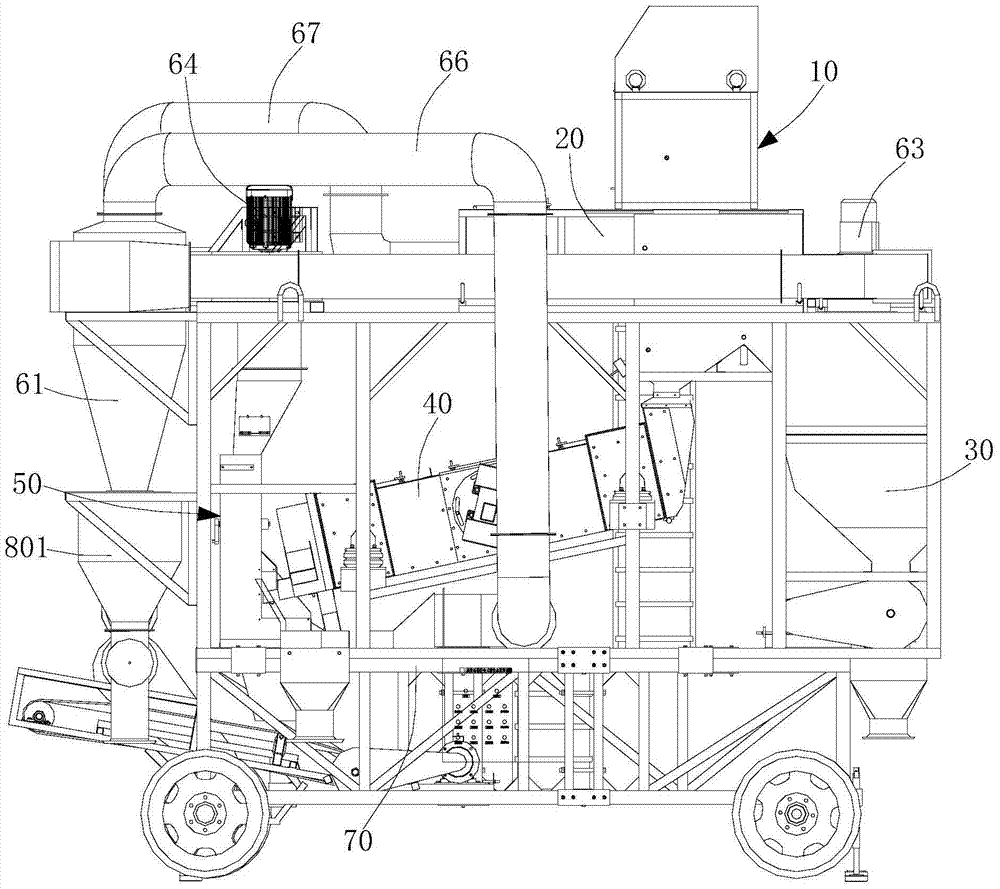

[0040] see figure 1 , figure 2 , image 3 and Figure 4 . For clarity, Figure 4 The horizontal wind selection channel 20 and part of the third air duct 67 are omitted.

[0041] The impurity cleaning equipment before the grain enters the warehouse according to an embodiment of the present invention includes a feeding mechanism 10, a horizontal air selection channel 20, a gravity settling chamber 30, a vibrating screen machine 40, a vertical air selection channel 50, and a first cyclone separator 61 , the second cyclone separator 62 and the supporting frame 70;

[0042] The top of the gravity settling chamber 30 is provided with a first centrifugal blower 63, the top of the vertical wind selection channel 50 is provided with a second centrifugal fan 64, and the feeding mechanism 10 is installed at the inlet of the horizontal wind selection channel 20. At the feed por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com