Outboard maintenance tool testing method

A technology of maintenance tools and test methods, which is applied in the field of manned space vehicles, can solve the problems of not being able to combine maintenance products at the same time, and simulate the pressure difference between the inside and outside of space suit gloves, so as to improve objectivity and accuracy, ensure consistency, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

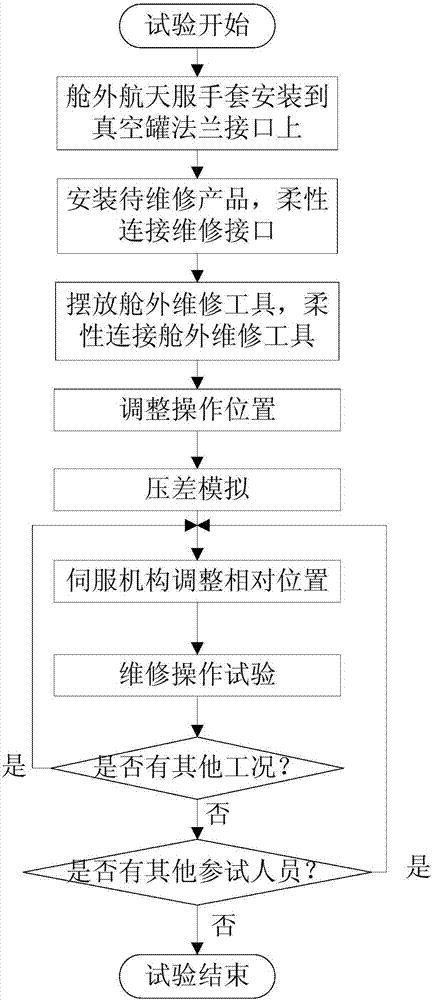

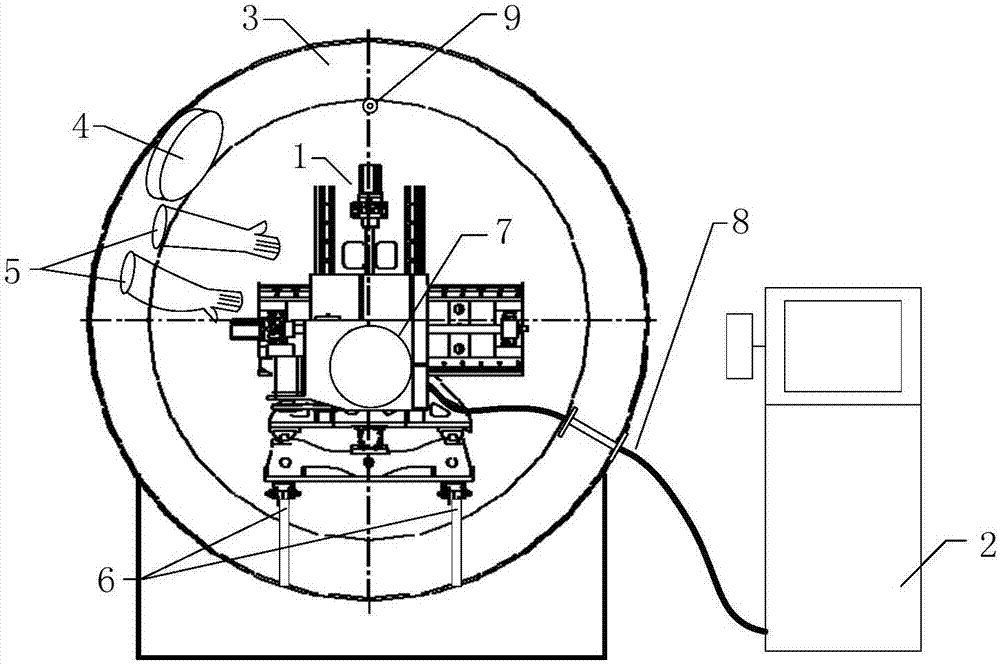

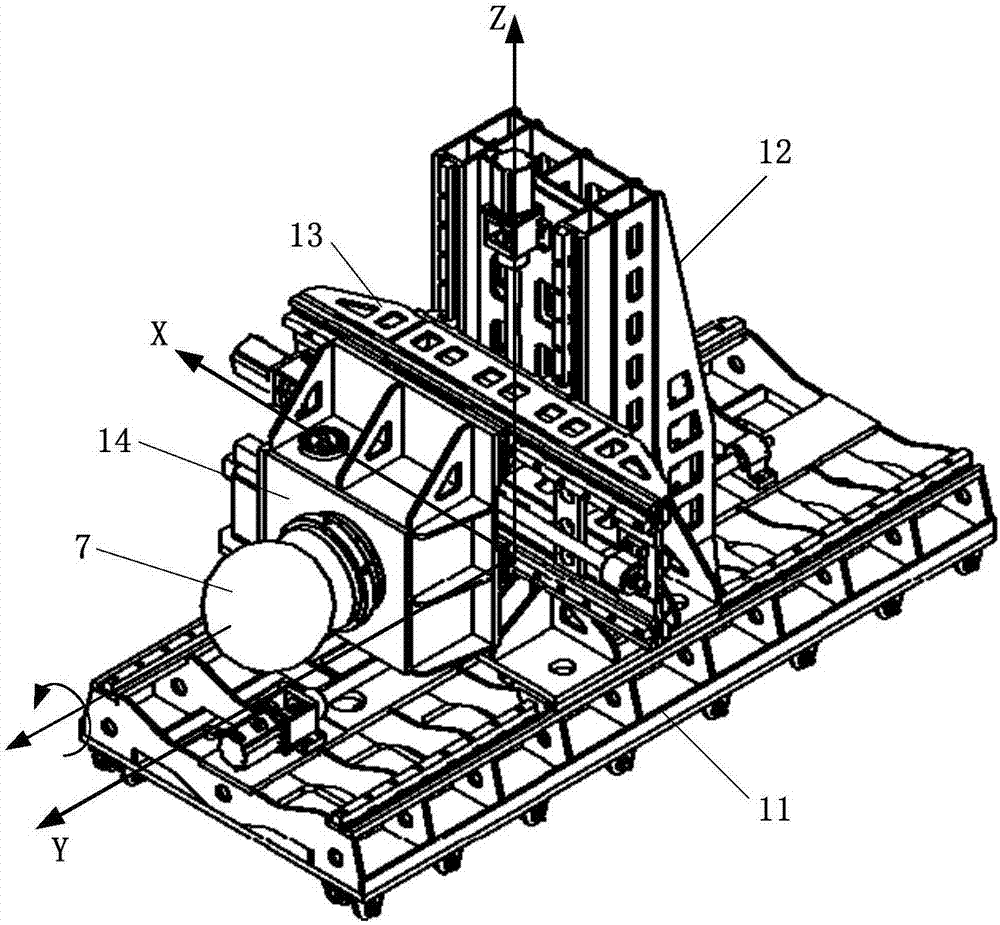

[0076] Follow the steps of this test method, such as figure 1 As shown, four kinds of extravehicular maintenance tools for manned spacecraft were tested. Using the vacuum tank control system, the door of the vacuum tank was opened, and an M6 inner hexagonal wrench was used to install the extravehicular spacesuit gloves on the vacuum tank. Through four M10 Install the maintenance equipment simulation part on the servo mechanism with screws, and use nylon rope to flexibly connect the maintenance interface on the maintenance equipment simulation part to the servo mechanism turntable frame to prevent the maintenance interface from falling during the test and damage the test equipment. The maintenance interface includes mechanical Adapter, M5 non-removable fastening device, J599 electrical connector, J14T electrical connector and J36A electrical connector; use nylon rope to flexibly connect the external maintenance tool to the top of the vacuum tank, and the position of the external...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com