All-in-one machine equipment used for automatic production of electronic component

An electronic component and all-in-one technology, which is applied in the production industry of electronic components, electronic component testing, sorting, laser, packaging, and can solve problems such as increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

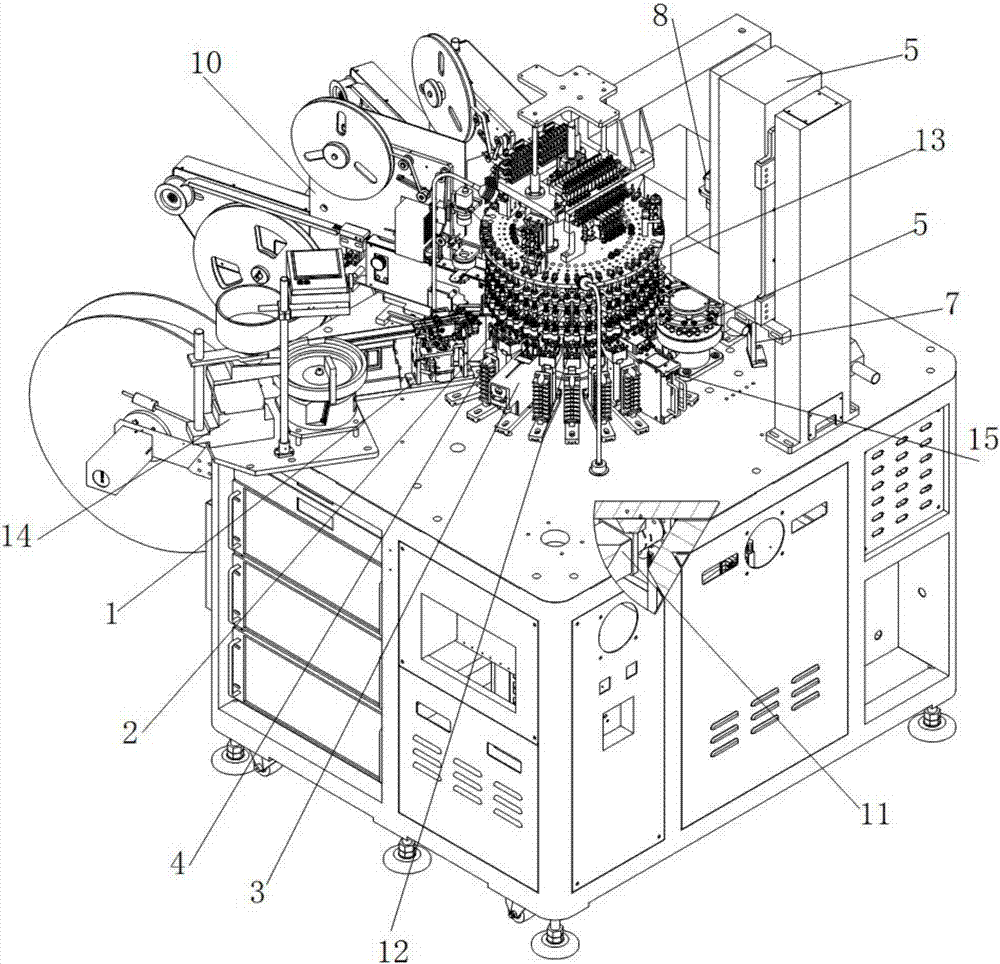

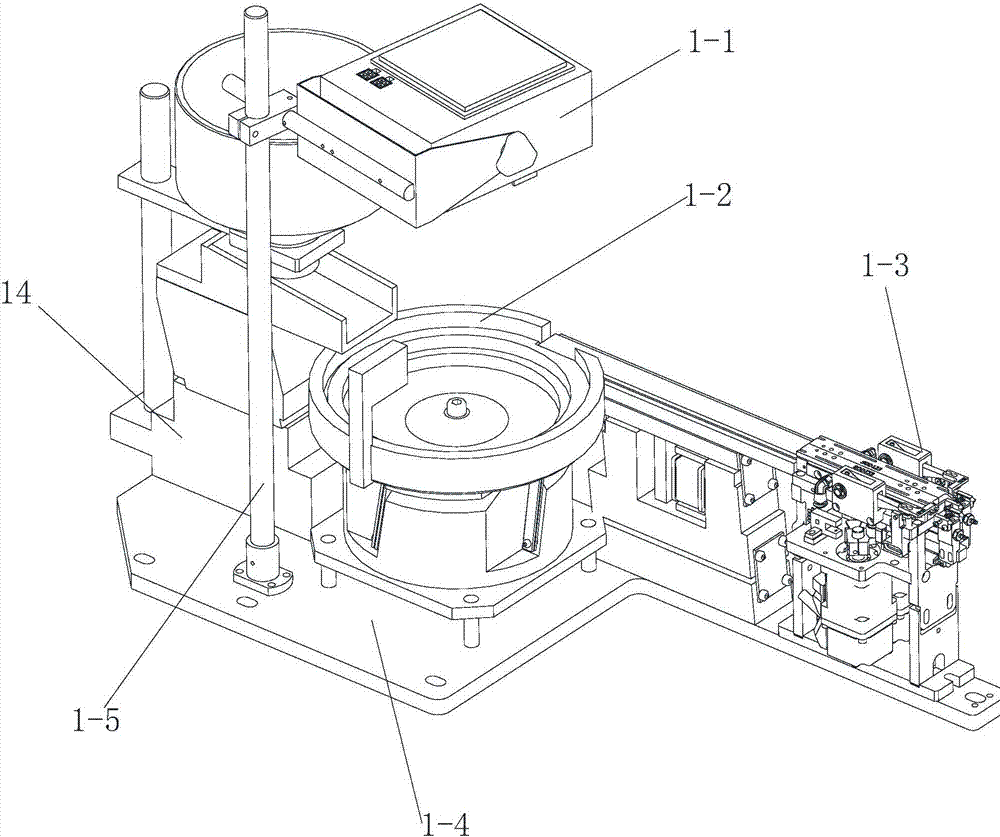

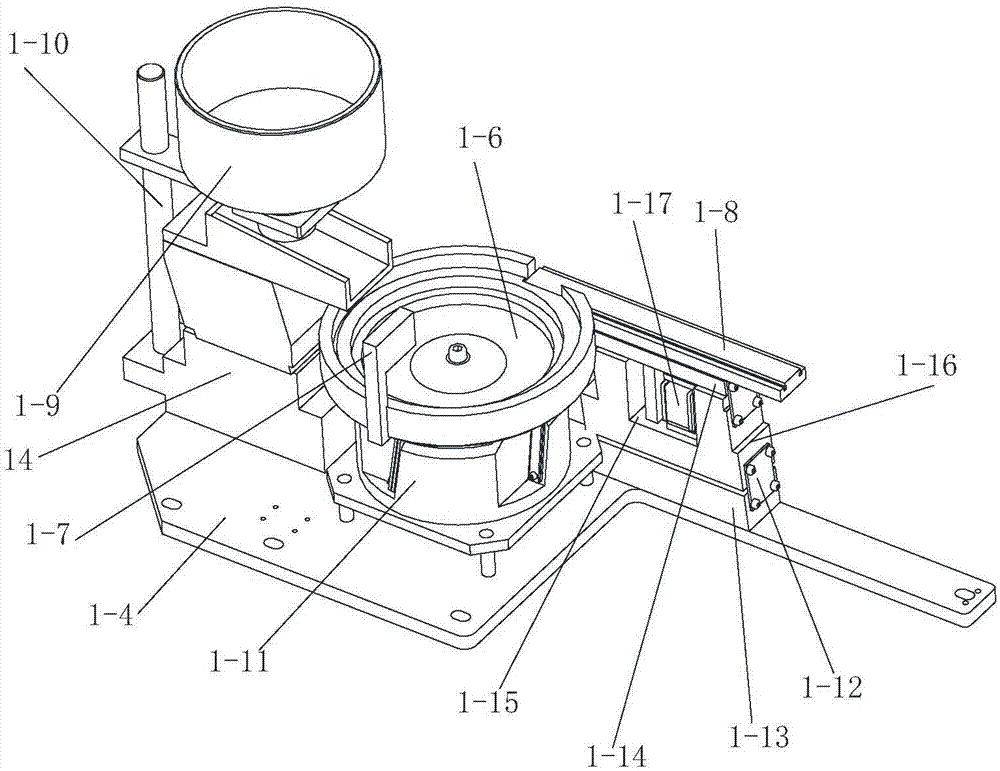

[0056] Such as figure 1 As shown, an all-in-one device for automatic production of electronic components includes a body 16, a transmission mechanism 11, a feeding mechanism 1, a packaging mechanism 10 and a discharge mechanism 15; the transmission mechanism 11 is arranged on the body 16 Inside: the feeding mechanism 1, packaging mechanism 10 and discharge mechanism 15 are arranged on the upper surface of the body 16, which also includes a positioning mechanism 2, a rotating mechanism 3, a testing mechanism 4, a B disk mechanism 5, a laser mechanism 6, and a brush Mechanism 7, 2D MI SI mechanism 8, 3D5S LI mechanism, large plate mechanism 12 and Z-axis mechanism; said Z-axis mechanism is arranged above the large plate mechanism 12; said large plate mechanism 12 and Z-axis mechanism rotate sync...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com